A kind of polyamide material with high friction coefficient and its preparation method and application

A high friction coefficient, polyamide technology, applied in the field of wear-resistant materials, can solve the problems of small friction damping of side bearing wear plates, unfavorable promotion, increased damping and energy dissipation capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: Preparation of high friction coefficient polyamide material

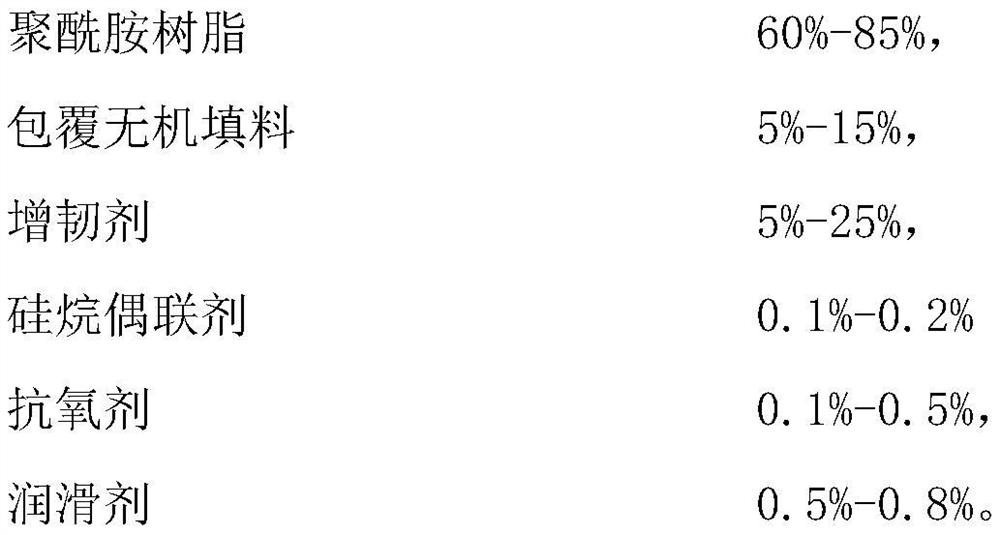

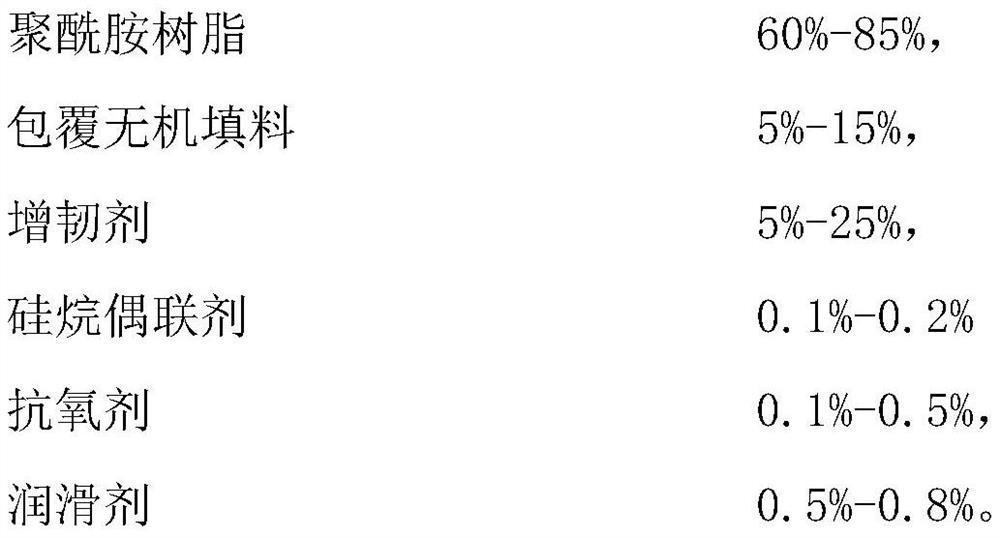

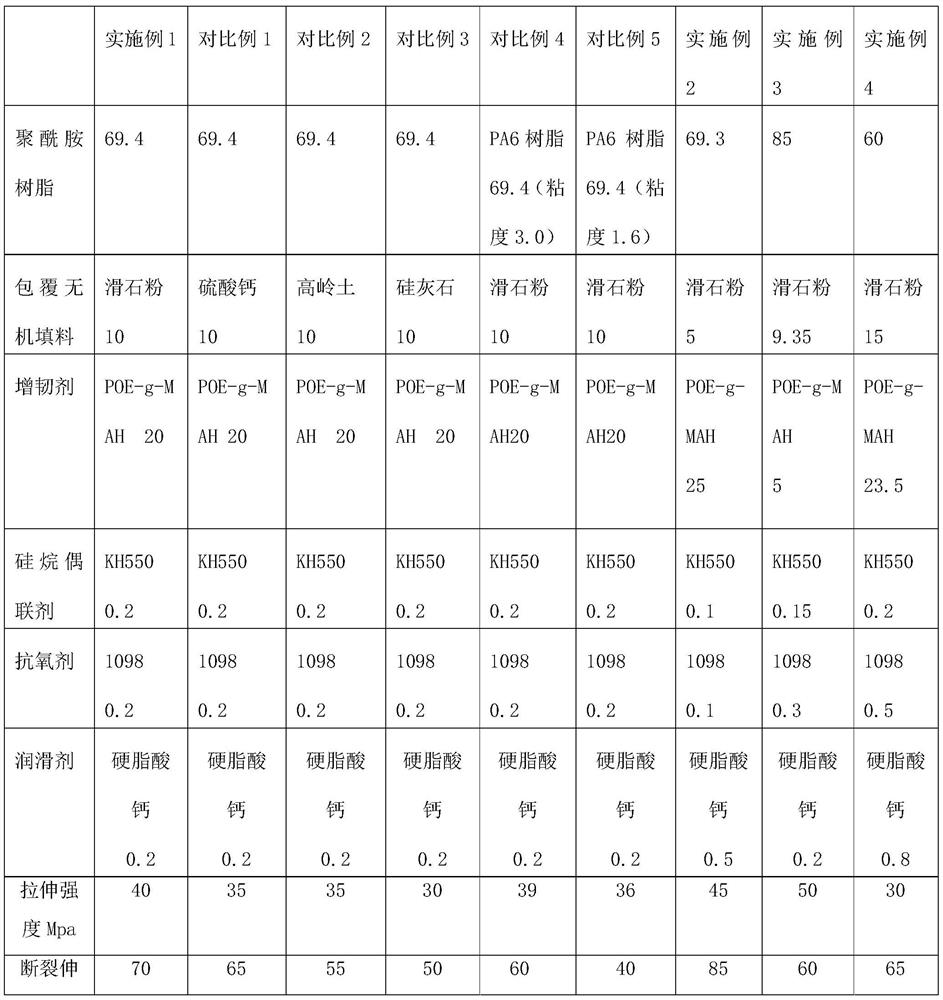

[0036] Raw materials: see Table 1

[0037] Preparation method: Add PA6 resin, coated inorganic filler, toughener, antioxidant and lubricant into a high-speed mixer for stirring

[0038] The mixture obtained above is granulated through a co-rotating intermeshing twin-screw extruder to prepare a polyamide material with a high coefficient of friction.

[0039] The obtained high friction coefficient polyamide material was injection molded into a flat plate, and the basic mechanical properties were measured by proofing. The static friction coefficient was tested according to the ISO8295 standard, as shown in Table 1.

Embodiment 2

[0040] Embodiment 2: Preparation of high friction coefficient polyamide material

[0041] Raw materials: see Table 1

[0042] Preparation method: with embodiment 1

[0043] The obtained high friction coefficient polyamide material was injection molded into a flat plate, and the basic mechanical properties were measured by proofing. The static friction coefficient was tested according to the ISO8295 standard, as shown in Table 1.

Embodiment 3

[0044] Embodiment 3: Preparation of high friction coefficient polyamide material

[0045] Raw materials: see Table 1

[0046] Preparation method: with embodiment 1

[0047] The obtained high friction coefficient polyamide material was injection molded into a flat plate, and the basic mechanical properties were measured by proofing. The static friction coefficient was tested according to the ISO8295 standard, as shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com