High-leveling 50:50 polyester resin for MDF materials, as well as preparation method and application thereof

A polyester resin and leveling technology, used in polyester coatings, epoxy resin coatings, coatings, etc., can solve the problems of insufficient segment flexibility, poor surface leveling performance and high activity of powder coatings, and meet the needs of The effect of coating effect requirements, long gel time and low melt viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

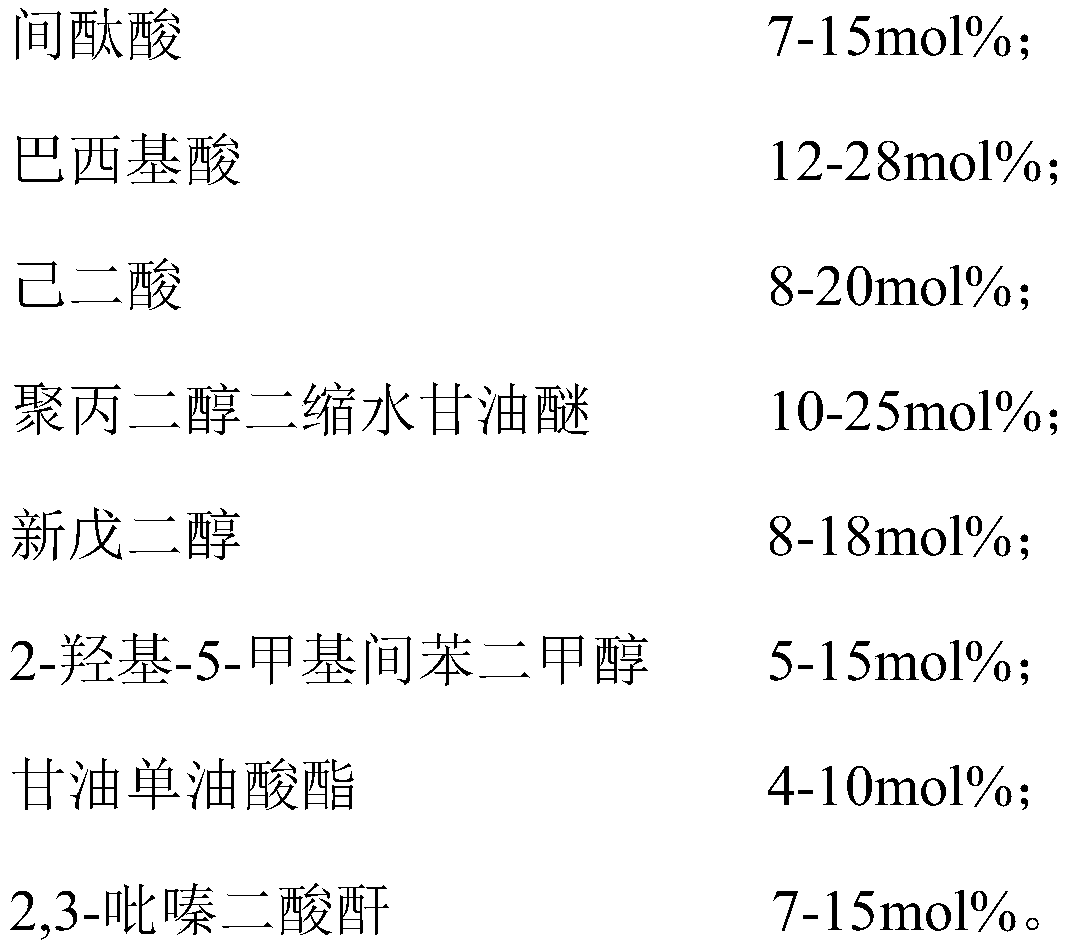

[0027] The high-leveling 50:50 polyester resin used for MDF material in this embodiment, based on the total amount of raw materials prepared by the polyester resin, includes the following raw material components in mole percentages:

[0028]

[0029] The preparation method of the high-leveling 50:50 polyester resin for MDF material in this embodiment includes the following steps:

[0030] (1) Take the polypropylene glycol diglycidyl ether and neopentyl glycol in the formula amount into the reaction kettle, and control the temperature to be lower than 140°C for heating and melting, and stir well;

[0031] (2) Add the formula amount of the isophthalic acid and the brasilic acid to the above mixture material, and add the formula amount of the catalyst at the same time, and gradually raise the temperature to 190°C at a temperature increase rate of 10°C / h for the heat preservation reaction 2- 4h, until the acid value of the reactant is less than 80mgKOH / g;

[0032] (3) Continue to add form...

Embodiment 2

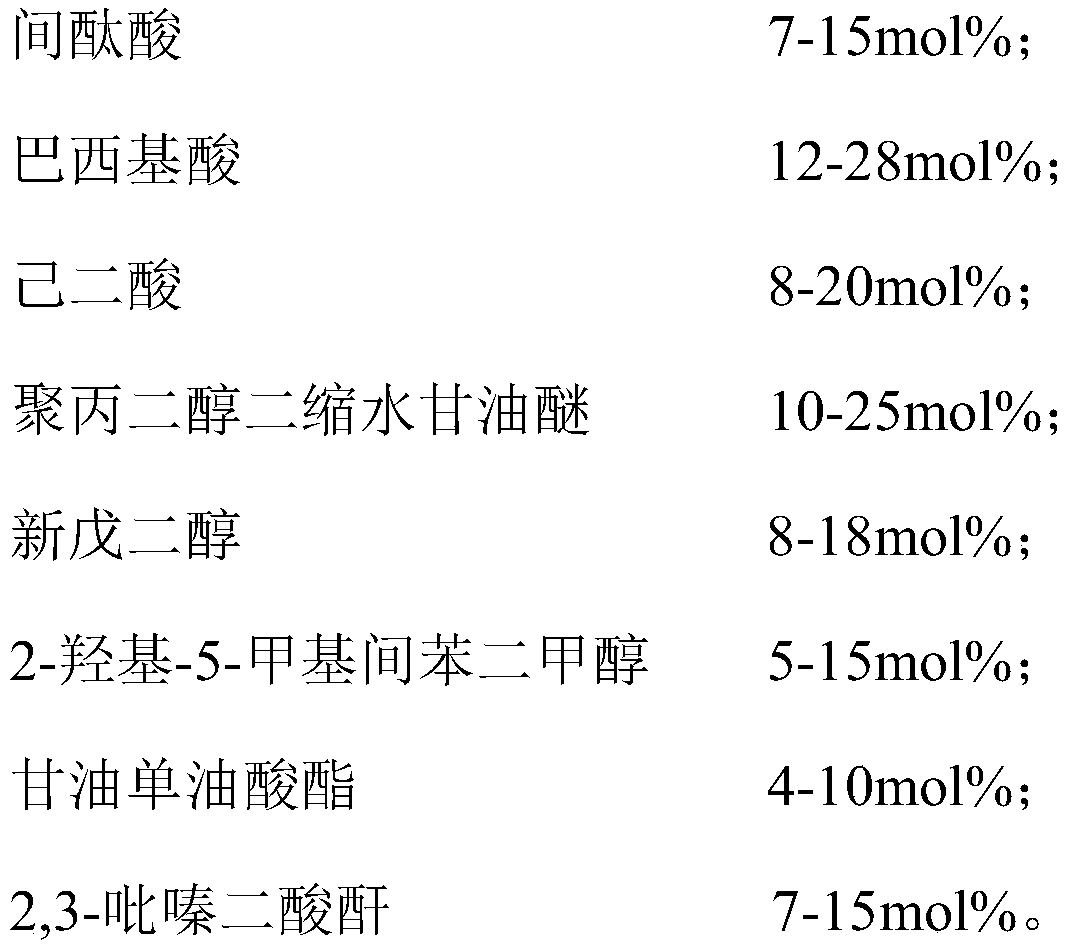

[0037] The high-leveling 50:50 polyester resin used for MDF material in this embodiment, based on the total amount of raw materials prepared by the polyester resin, includes the following raw material components in mole percentages:

[0038]

[0039]

[0040] The preparation method of the high-leveling 50:50 polyester resin for MDF material in this embodiment includes the following steps:

[0041] (1) Take the polypropylene glycol diglycidyl ether and neopentyl glycol in the formula amount into the reaction kettle, and control the temperature to be lower than 140°C for heating and melting, and stir well;

[0042] (2) Add the formula amount of the isophthalic acid and the brasilic acid to the above mixture material, and add the formula amount of the catalyst at the same time, and gradually increase the temperature to 210°C at a temperature increase rate of 10°C / h for the heat preservation reaction 2- 4h, until the acid value of the reactant is less than 80mgKOH / g;

[0043] (3) Continue...

Embodiment 3

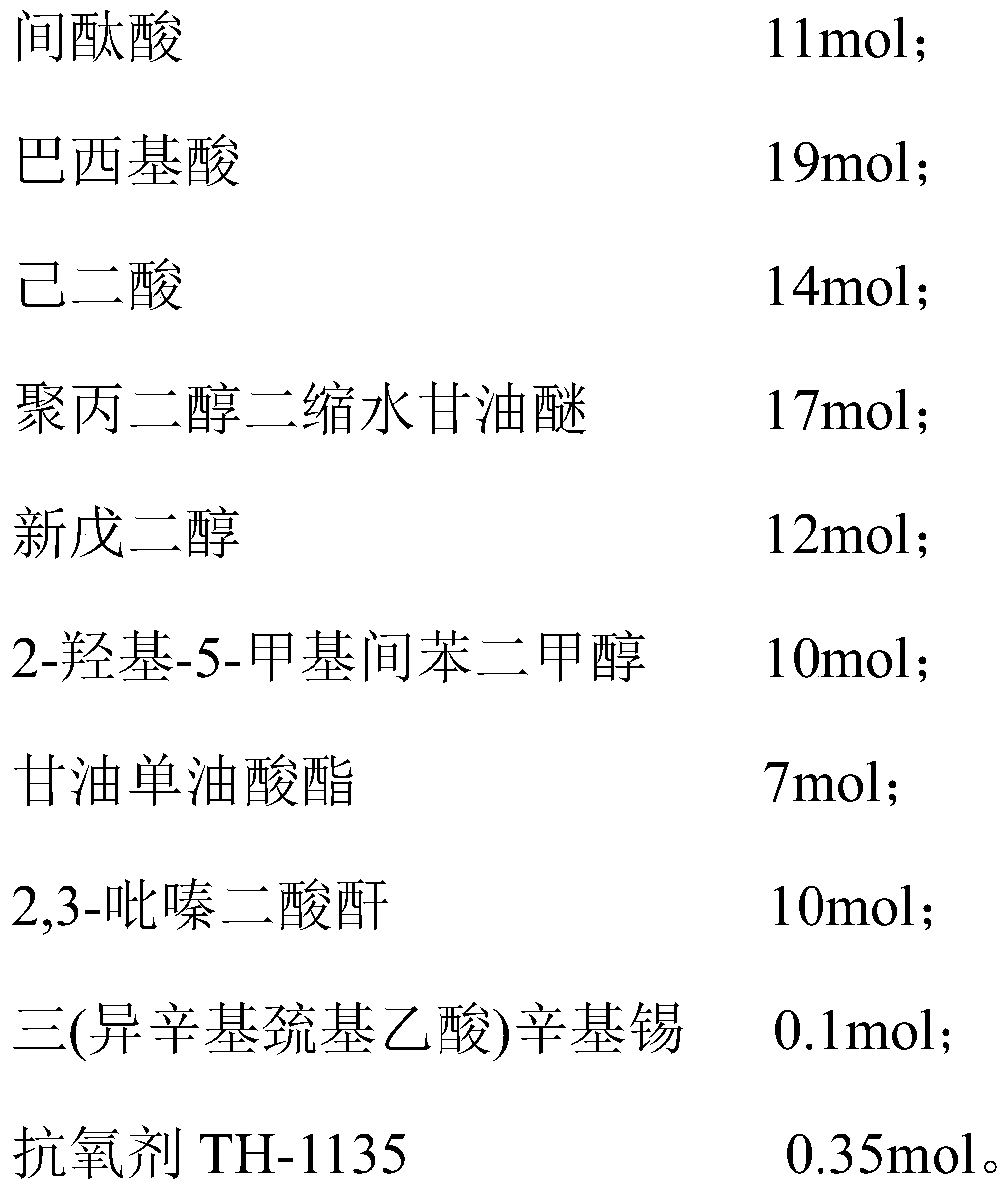

[0048] The high-leveling 50:50 polyester resin used for MDF material in this embodiment, based on the total amount of raw materials prepared by the polyester resin, includes the following raw material components in mole percentages:

[0049]

[0050] The preparation method of the high-leveling 50:50 polyester resin for MDF material in this embodiment includes the following steps:

[0051] (1) Take the polypropylene glycol diglycidyl ether and neopentyl glycol in the formula amount into the reaction kettle, and control the temperature to be lower than 140°C for heating and melting, and stir well;

[0052] (2) Add the formula amount of the isophthalic acid and the brasilic acid to the above mixture material, and add the formula amount of the catalyst at the same time, and gradually raise the temperature to 200°C at a temperature increase rate of 10°C / h for the heat preservation reaction 2- 4h, until the acid value of the reactant is less than 80mgKOH / g;

[0053] (3) Continue to add form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com