Production method of fast scarlet base G

A production method, red-based technology, applied in chemical instruments and methods, preparation of amino compounds, preparation of organic compounds, etc., can solve the problems of difficult disposal of waste acid, low yield, high energy consumption, etc., to reduce the concentration of nitric acid, production The effect of low risk and controlled reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The production method of a kind of bright red base G of the present embodiment is characterized in that, comprises the steps:

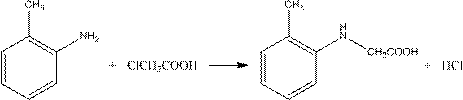

[0028] a) Salt formation: pump o-methylaniline and glacial acetic acid into the reaction kettle, then add chloroacetic acid, raise the temperature to about 60°C, and extract the hydrogen chloride gas generated by the reaction through a micro-vacuum;

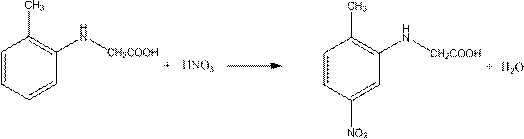

[0029] b) Nitrification: Control the temperature at 30°C, and add the mixture of glacial acetic acid and nitric acid dropwise from the high-level tank;

[0030] c) After the dropwise addition is completed, stir evenly and put it into the separation kettle, then pump methyl tert-butyl ether into the separation kettle, and separate the solid to the double decomposition kettle through pressure filtration, and the liquid to the distillation kettle;

[0031] d) Heating the distillation kettle to 55°C, condensing and recovering methyl tert-butyl ether and remaining glacial acetic acid;

[0032] e) Meta...

Embodiment 2

[0034] The production method of a kind of bright red base G of the present embodiment is characterized in that, comprises the steps:

[0035] b) Salt formation: pump o-methylaniline and glacial acetic acid into the reaction kettle, then add chloroacetic acid, raise the temperature to 62°C, and extract the hydrogen chloride gas generated by the reaction through a slight vacuum;

[0036] b) Nitrification: Control the temperature at 32°C, and add the mixture of glacial acetic acid and nitric acid dropwise from the elevated tank;

[0037] c) After the dropwise addition is completed, stir evenly and put it into the separation kettle, then pump methyl tert-butyl ether into the separation kettle, and separate the solid to the double decomposition kettle through pressure filtration, and the liquid to the distillation kettle;

[0038] d) Heating the distillation kettle to 55°C, condensing and recovering methyl tert-butyl ether and remaining glacial acetic acid;

[0039] e) Metathesis:...

Embodiment 3

[0041] The production method of a kind of bright red base G of the present embodiment is characterized in that, comprises the steps:

[0042] c) Salt formation: pump o-methylaniline and glacial acetic acid into the reaction kettle, then add chloroacetic acid, raise the temperature to 65°C, and extract the hydrogen chloride gas generated by the reaction through a slight vacuum;

[0043] b) Nitrification: Control the temperature at 35°C, and add the mixture of glacial acetic acid and nitric acid dropwise from the elevated tank;

[0044] c) After the dropwise addition is completed, stir evenly and put it into the separation kettle, then pump methyl tert-butyl ether into the separation kettle, and separate the solid to the double decomposition kettle through pressure filtration, and the liquid to the distillation kettle;

[0045] d) Heating the distillation kettle to 56°C, condensing and recovering methyl tert-butyl ether and remaining glacial acetic acid;

[0046] e) Metathesis:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com