Using method for feed pulverizer with separating screen

A sorting sieve and pulverizer technology, applied in the field of poultry breeding, can solve the problems of inability to meet the needs of pulverization, low degree of automation, poor pulverization effect, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

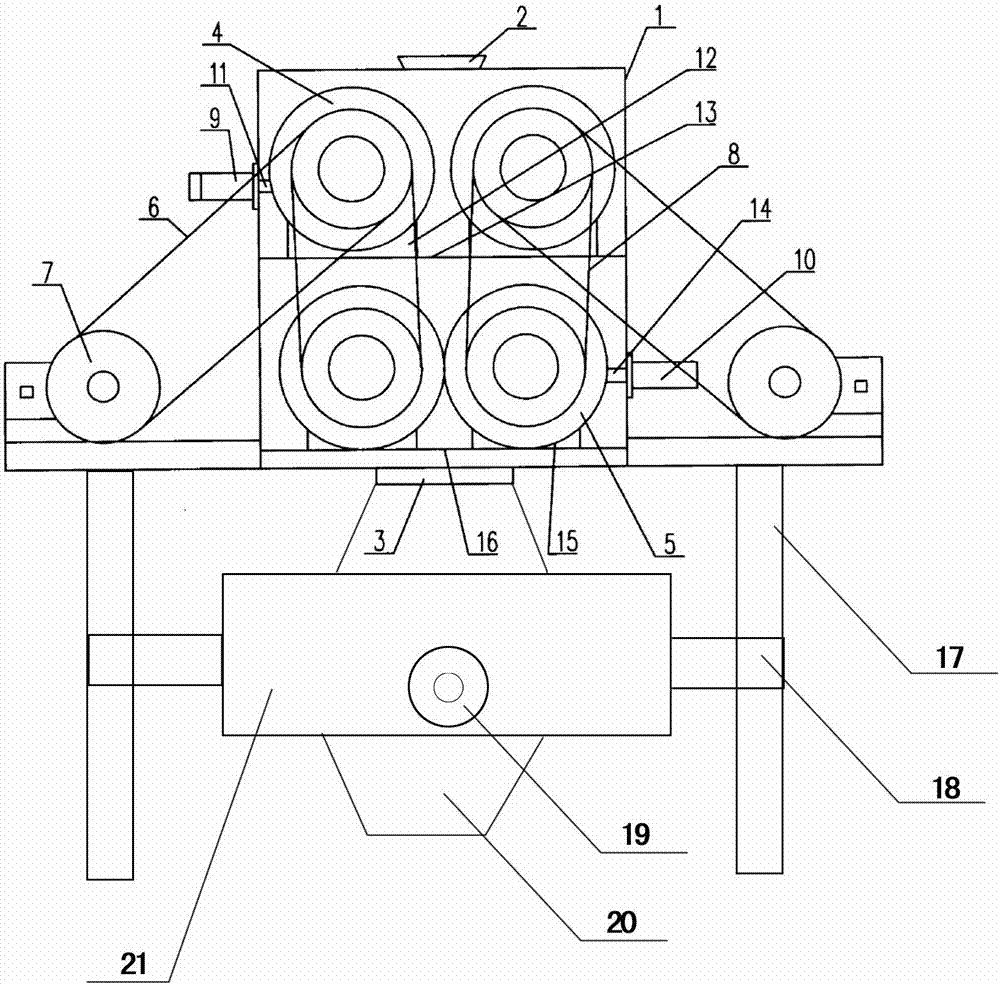

[0030] The present invention will be described below in conjunction with the accompanying drawings.

[0031] The use method of the feed grinder with sorting screen, wherein, comprises the following steps:

[0032] A. When working, the driving device of the control device drives the coarse crushing roller through the driving chain, and the coarse crushing roller drives the coarse crushing roller through the transmission chain. When raw materials such as corn and bones enter the gap between the coarse crushing rollers through the feeding port, the raw materials are crushed and crushed again through the gap between the coarse crushing rollers,

[0033] B. Adjust the coarse crushing wheel: the piston rod of the upper adjustment cylinder is controlled by the control device to push one of the coarse crushing rollers to slide on the slide rail to adjust the gap between the two coarse crushing rollers.

[0034] C. Adjust the fine crushing wheel: under the control of the control devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com