GO/NR composite preparation method and open mill for preparation thereof

A composite material and open mill technology, applied in the field of rubber mixing, can solve the problems of filler reunion, large water consumption, long time consumption, etc., achieve low energy consumption and production cost, reduce time and frequency, and use environmentally friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

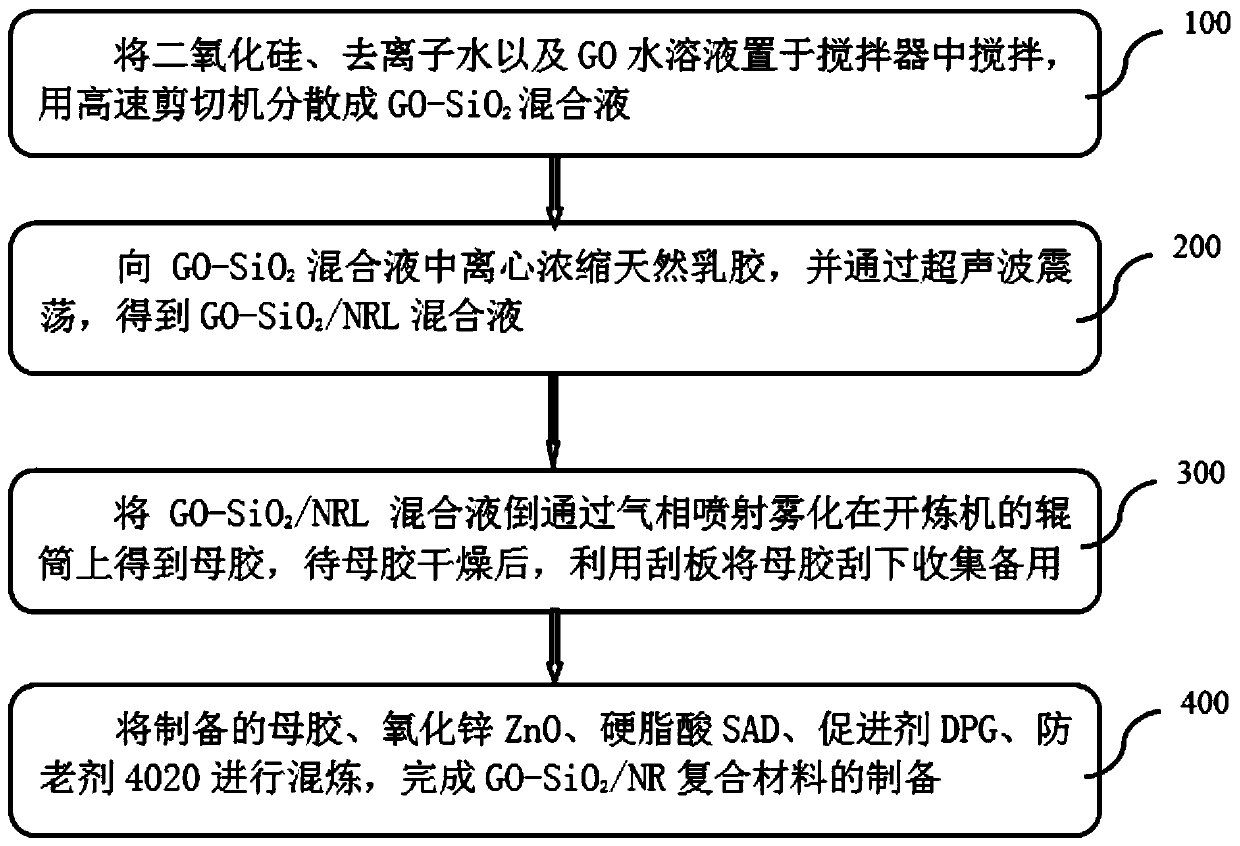

[0040] Such as figure 1 As shown, the invention provides a kind of GO / NR composite material preparation method, it is characterized in that: comprise the steps:

[0041] S100, put silica, deionized water and GO aqueous solution in a stirrer and stir, and then use a high-speed shearing machine to disperse into GO-SiO with a mass fraction of 25wt% 2 mixed solution;

[0042] S200, to GO-SiO 2 Add 100 parts by mass of centrifugally concentrated natural latex with a dry glue mass fraction of 60wt% to the mixture in two equal parts, and vibrate with ultrasonic waves to obtain GO-SiO 2 / NRL mixture;

[0043] S300, GO-SiO 2 / NRL mixed liquid is poured and atomized on the roller of the open mill to obtain the masterbatch through the gas phase spray device, and the temperature of the roller is adjusted to 150-160°C. Scrape off and collect for later use;

[0044] S400, plasticize the prepared masterbatch on the open mill, add the masterbatch, zinc oxide ZnO, stearic acid SAD, accel...

Embodiment 2

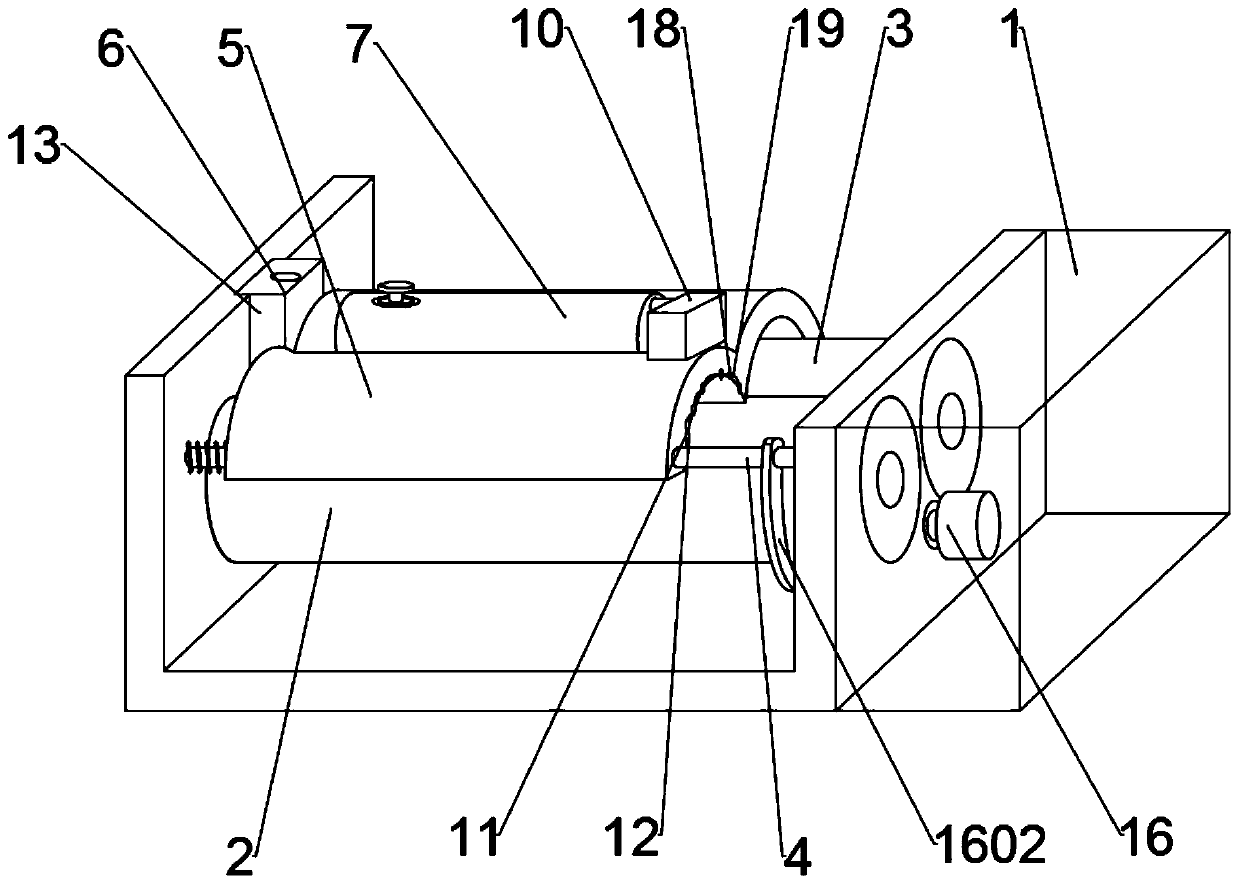

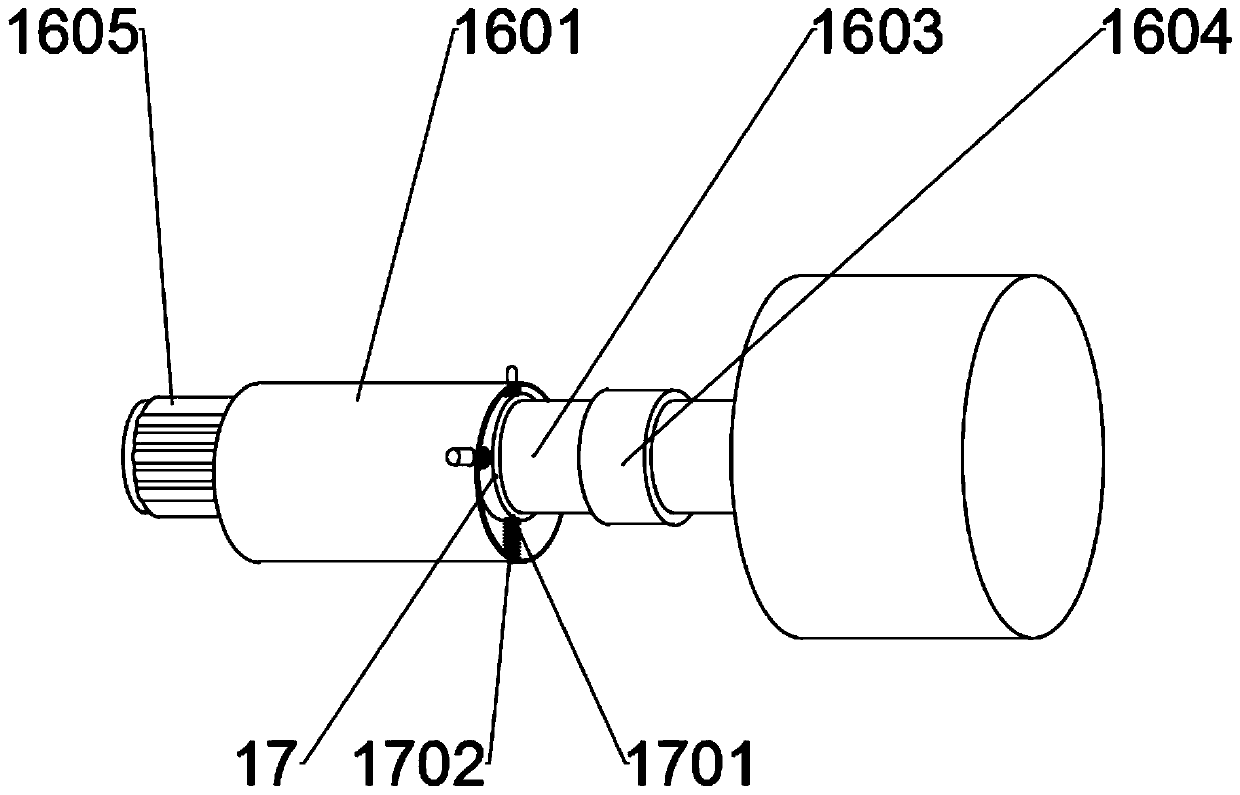

[0050] Such as Figure 2 to Figure 5 As shown, the present invention also provides an open mill for the preparation of GO / NR composite materials in Example 1, including a base 1 and a front roller 2 and a rear roller 3 installed on the base 1, the front roller 2 and The top of the rear roller 3 is movably installed with a cover plate 5 through the guide rail bar 4, and the two ends of the cover plate 5 are provided with a micro-motion assembly 6 that drives the cover plate 5 to reciprocate on the guide rail bar 4, and the top of the cover plate 5 is installed in the middle Rubber material pipe 7, rubber material pipe 7 comprises material storage pipe 8 and feed pipe 9, is provided with pressure control valve 10 on the connecting pipeline between material storage pipe 8 and feed pipe 9, and the back side of cover plate 5 is along the roller There are several lumen tubes 11 in an array at equal intervals in the length direction of the wheel, and the feeding pipe 9 is connected t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com