A resource utilization method of landfill leachate

A landfill leachate recycling technology, which is applied in the field of landfill leachate resource utilization, can solve the problems that pellets are difficult to meet, and achieve the effect of realizing secondary economic value, simple method, and feasible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

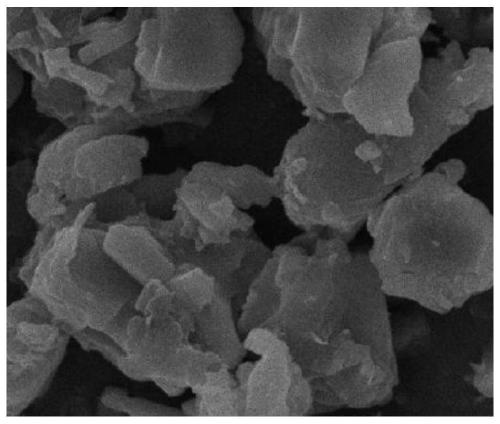

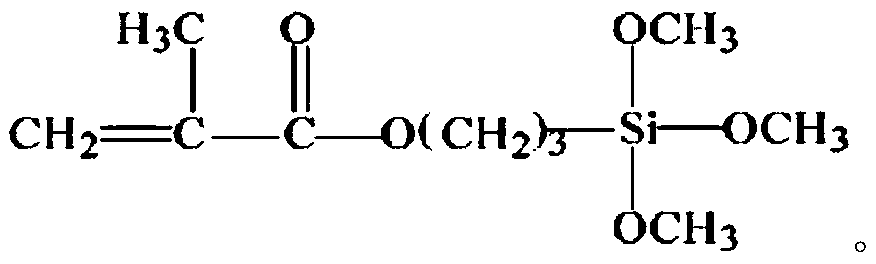

Image

Examples

Embodiment 1

[0031] A resource utilization method of landfill leachate, mixing and mixing the landfill leachate concentrate with a solid content of 30% and sodium hydroxide solution, stirring and reacting in a water bath at 80°C, and then cooling the solution , the modified landfill leachate can be obtained, and the prepared modified landfill leachate is mixed with cement and modified dolomite in proportion, and after spray drying, the composite iron ore pellet sticky binder; the prepared composite iron ore pellet binder is added to the iron ore concentrate by 3% of the iron concentrate mass to prepare iron ore pellets.

[0032] Wherein, the mixed mass parts of the modified landfill leachate, cement and modified dolomite are: 40 parts of modified landfill leachate, 25 parts of cement, and 10 parts of modified dolomite.

[0033] Wherein, the modified dolomite is prepared by the following method:

[0034] S1 grinds dolomite to 400 mesh to obtain dolomite powder;

[0035] S2 Weigh a certain...

Embodiment 2

[0042] A resource utilization method of landfill leachate, mixing and mixing the landfill leachate concentrate with a solid content of 35% and sodium hydroxide solution, stirring and reacting in a water bath at 85°C, and then cooling the solution , the modified landfill leachate can be obtained, and the prepared modified landfill leachate is mixed with cement and modified dolomite in proportion, and after spray drying, the composite iron ore pellet sticky binder; the prepared composite iron ore pellet binder is added to the iron ore concentrate by 3% of the iron concentrate mass to prepare iron ore pellets.

[0043] Wherein, the mixed mass parts of the modified landfill leachate, cement and modified dolomite are: 45 parts of modified landfill leachate, 28 parts of cement, and 13 parts of modified dolomite.

[0044] Wherein, the modified dolomite is prepared by the following method:

[0045] S1 grinds dolomite to 500 mesh to obtain dolomite powder;

[0046] S2 Weigh a certain...

Embodiment 3

[0053] A resource utilization method of landfill leachate, mixing and mixing the landfill leachate concentrate with a solid content of 40% and sodium hydroxide solution, stirring and reacting in a water bath at 90°C, and then cooling the solution , the modified landfill leachate can be obtained, and the prepared modified landfill leachate is mixed with cement and modified dolomite in proportion, and after spray drying, the composite iron ore pellet sticky binder; the prepared composite iron ore pellet binder is added to the iron ore concentrate by 3% of the iron concentrate mass to prepare iron ore pellets.

[0054] Wherein, the mixed mass parts of the modified landfill leachate, cement and modified dolomite are: 50 parts of modified landfill leachate, 30 parts of cement, and 15 parts of modified dolomite.

[0055] Wherein, the modified dolomite is prepared by the following method:

[0056] S1 grinds dolomite to 600 mesh to obtain dolomite powder;

[0057] S2 Weigh a certain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com