Device and method for removing burrs in a cracked waveguide inner cavity

A burr removal and waveguide technology, which is applied in the field of cracked waveguide cavity burr removal devices, can solve the problems of difficult quality assurance, short service life, easy displacement and damage of sandpaper, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

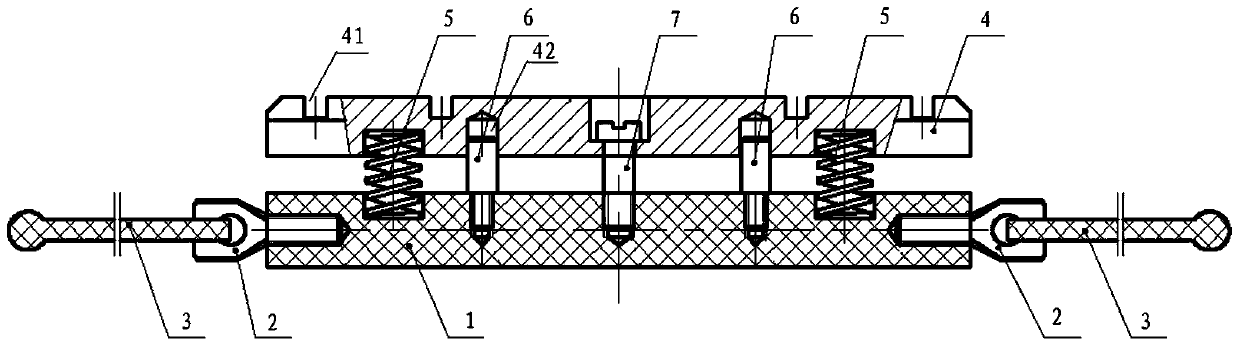

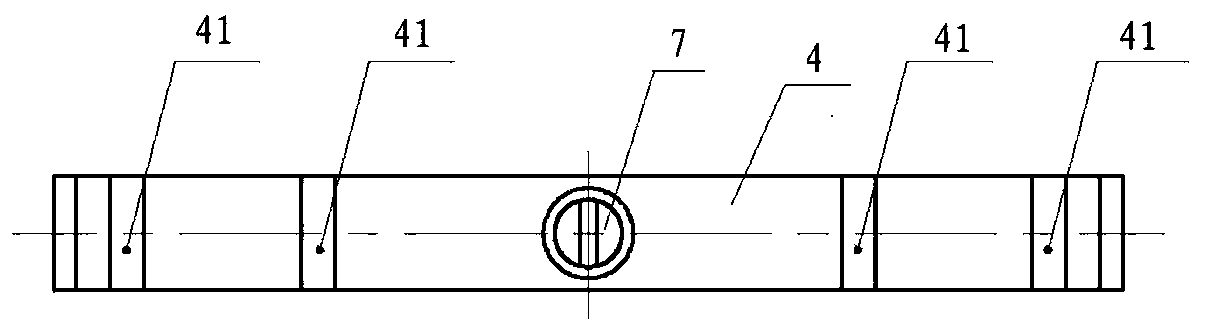

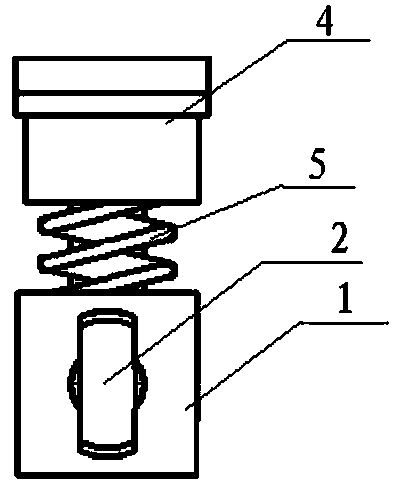

[0042] Such as Figure 1-4 As shown, a device for removing burrs in the cavity of a cracked waveguide includes a base 1, a deburring device 4 and an adjustment device, and the deburring device 4 is installed on the base 1 in a liftable manner through the adjustment device; the The deburring device 4 is provided with several burr collection grooves 41; wherein, the burr collection groove 41 is moved so that the burr 82 in the inner cavity of the crack waveguide 8 is cut and removed by the edge of the open end, and collected in the In the burr collection tank 41. Preferably, the base 1 is made of bakelite sticks, which can protect the inner wall of the inner cavity and avoid scratches.

[0043] The beneficial effect of this embodiment is: adjust the height of the thorn removing device 4 relative to the base 1 through the adjusting device, and the thorn removing device 4 descends relative to the base 1, reducing the height of the present invention, which can facilitate the present...

Embodiment 2

[0045] Such as Figure 1-4 As shown, a device for removing burrs in the cavity of a cracked waveguide includes a base 1, a deburring device 4 and an adjustment device, and the deburring device 4 is installed on the base 1 in a liftable manner through the adjustment device; the The deburring device 4 is provided with several burr collection grooves 41; wherein, the burr collection groove 41 is moved so that the burr 82 in the inner cavity of the crack waveguide 8 is cut and removed by the edge of the open end, and collected in the In the burr collection tank 41.

[0046] Preferably, the material of the base 1 is a Bakelite stick, which is an epoxy phenolic laminated glass cloth stick (3722-3725, 3841) in this embodiment, which can protect the inner wall of the inner cavity and avoid scratches; the material of the destab device 4 is Tool steel (45# steel, alloy steel, etc.) ensures the sharpness of the knife edge and improves the efficiency of scraping and removing burrs 82; th...

Embodiment 3

[0079] A method for removing burrs in a cracked waveguide cavity, using the above-mentioned device for removing burrs in a cracked waveguide cavity, characterized in that it includes the steps of:

[0080] S1: Squeeze the burr 82 in the crack 81 of the cracked waveguide 8 into the inner cavity;

[0081]S2: After the deburring device 4 is lowered relative to the base 1 by the adjusting device, the device for removing burrs in the cavity of the cracked waveguide enters the cracked waveguide 8 from the waveguide opening of the cracked waveguide 8 Under the action of the adjustment device, the side of the puncture removal device 4 away from the base 1 and the side of the base 1 away from the puncture removal device 4 are respectively tightly abutted against the crack waveguide 8 on the inner wall of the cavity;

[0082] The device for removing burrs in the inner cavity of the cracked waveguide moves back and forth in the inner cavity of the cracked waveguide 8; during the movemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com