Small super-hard material grinding wheel segment deburring machine

A technology of grinding wheel segments and superhard materials, which is applied to the parts of grinding machine tools, machine tools suitable for grinding the edge of workpieces, grinding machines, etc. It can solve the problems of easy dust generation, time-consuming and labor-intensive scrap rate, etc., and achieve high work efficiency , Low manufacturing cost, and shortened working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

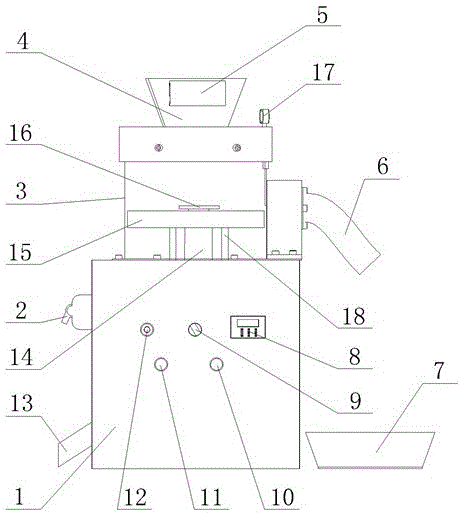

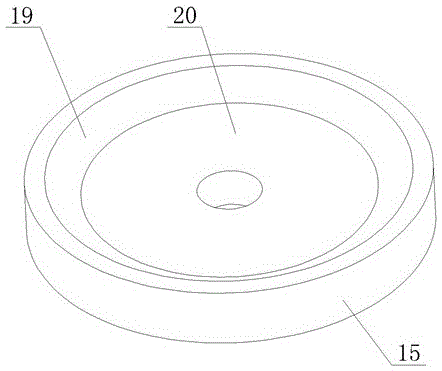

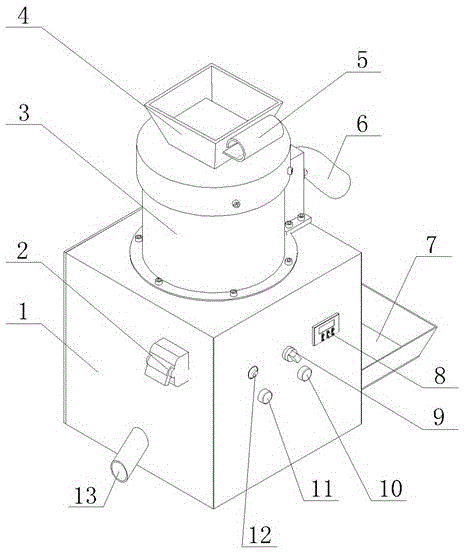

[0017] Such as figure 1 and figure 2 As shown, the present invention mainly comprises base 1, and base 1 is the housing of cubic shape, and outer cover 3 is fixed on the top of base 1, is provided with a plurality of openings between base 1 inside and outer cover 3, and this is for the dust that produces Fall into the inside of the base 1, and then be discharged through the waste outlet 13. A feed hopper 4 is arranged on the top of the outer cover 3, and a feed valve 5 is installed at the lower end of the feed hopper 4, and an outlet valve 5 is installed on the side of the outer cover 3. Feeding pipe 6, a discharge valve 17 is installed at the connection between the discharge port 6 and the outer cover 3, and a receiving box 7 is arranged at the lower end of the outlet of the discharge pipe 6. The outer cover 3, the feed valve 5, and the discharge valve The setting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com