Electrode for potential detection of electromagnetic flowmeter

An electromagnetic flowmeter and potential detection technology, which is used in the application of electromagnetic flowmeters to detect fluid flow, volume/mass flow generated by electromagnetic effects, measurement flow/mass flow, etc. Issues such as applying shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

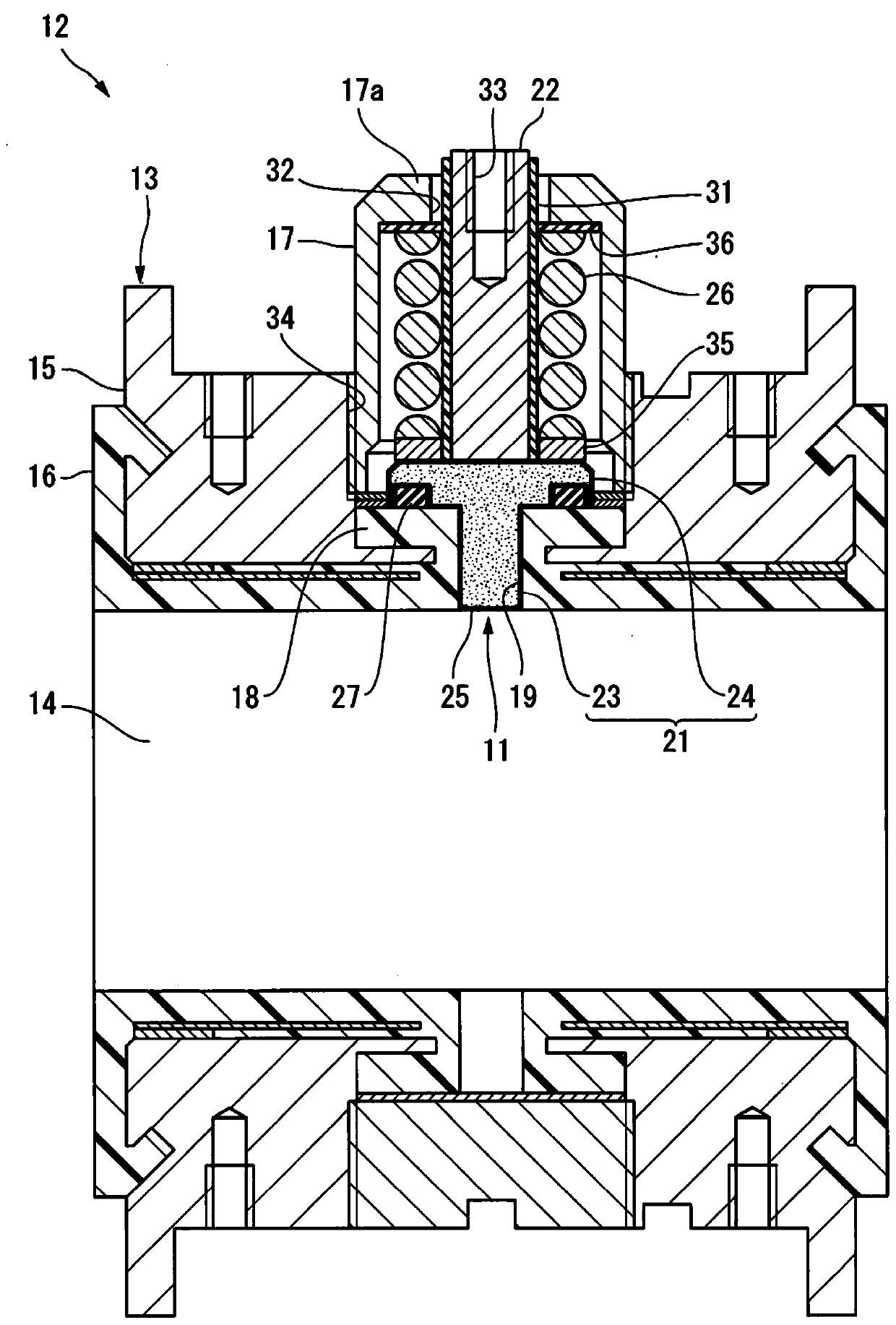

[0033] Below, refer to Figure 1 to Figure 5 One embodiment of the electrode for potential detection of the electromagnetic flowmeter of the present invention will be described in detail. The electrode for potential detection of the present embodiment is an example of the electrode for potential detection described in claim 1 and claim 3 .

[0034] figure 1 The shown potential detection electrode 11 (hereinafter simply referred to as the electrode 11 ) is attached to the measurement tube 13 of the electromagnetic flowmeter 12 from the outside of the fluid passage 14 .

[0035] The measuring tube 13 includes a main body 15 , a liner 16 provided on the inner surface of the main body 15 , a bottomed cylindrical electrode cap 17 for accommodating the electrode 11 , and the like. The electrode mount 18 is integrally provided on the liner 16 . An electrode insertion hole 19 into which the electrode 11 is inserted is perforated in the electrode mount 18 .

[0036] The electrode ...

no. 2 approach

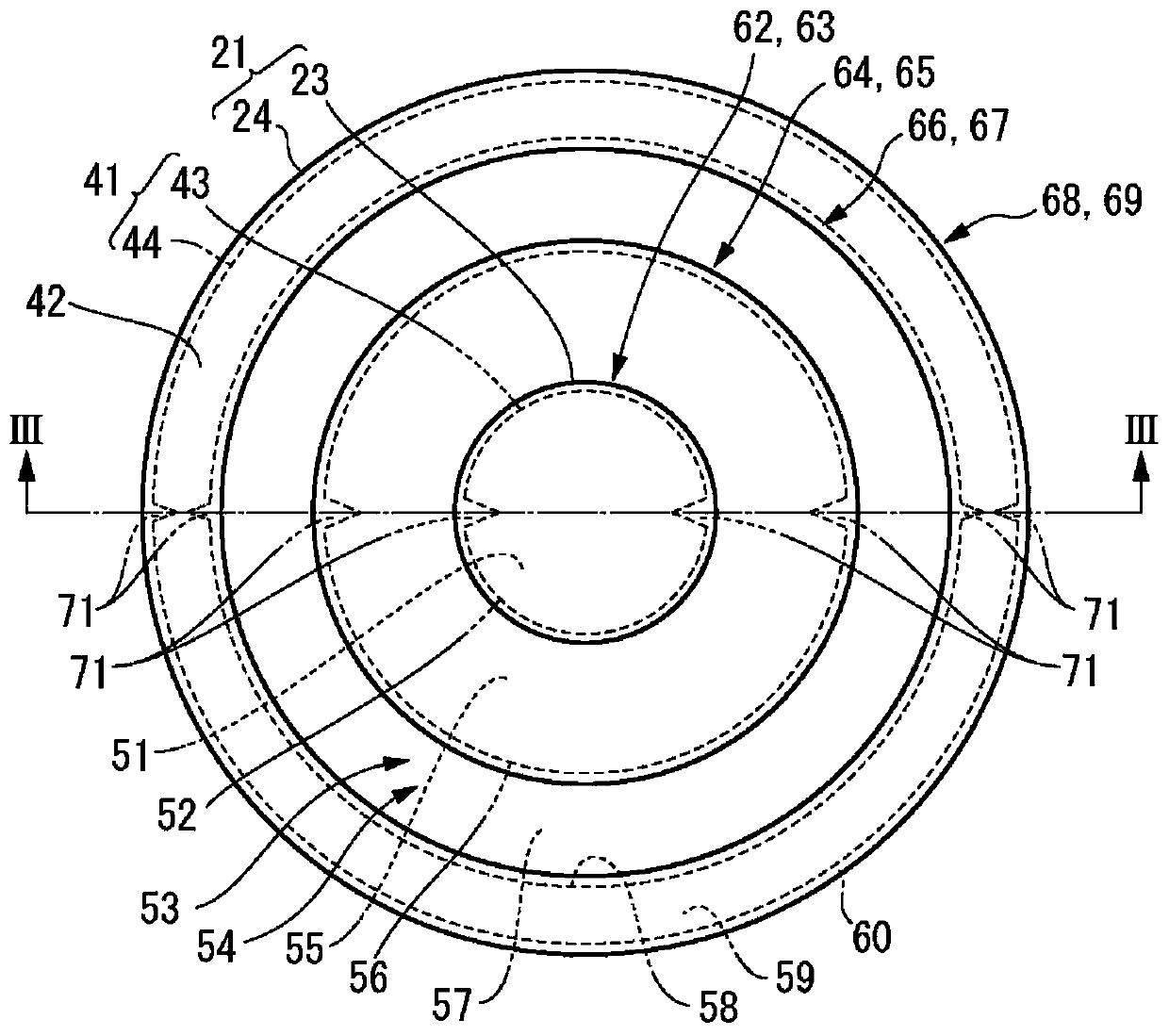

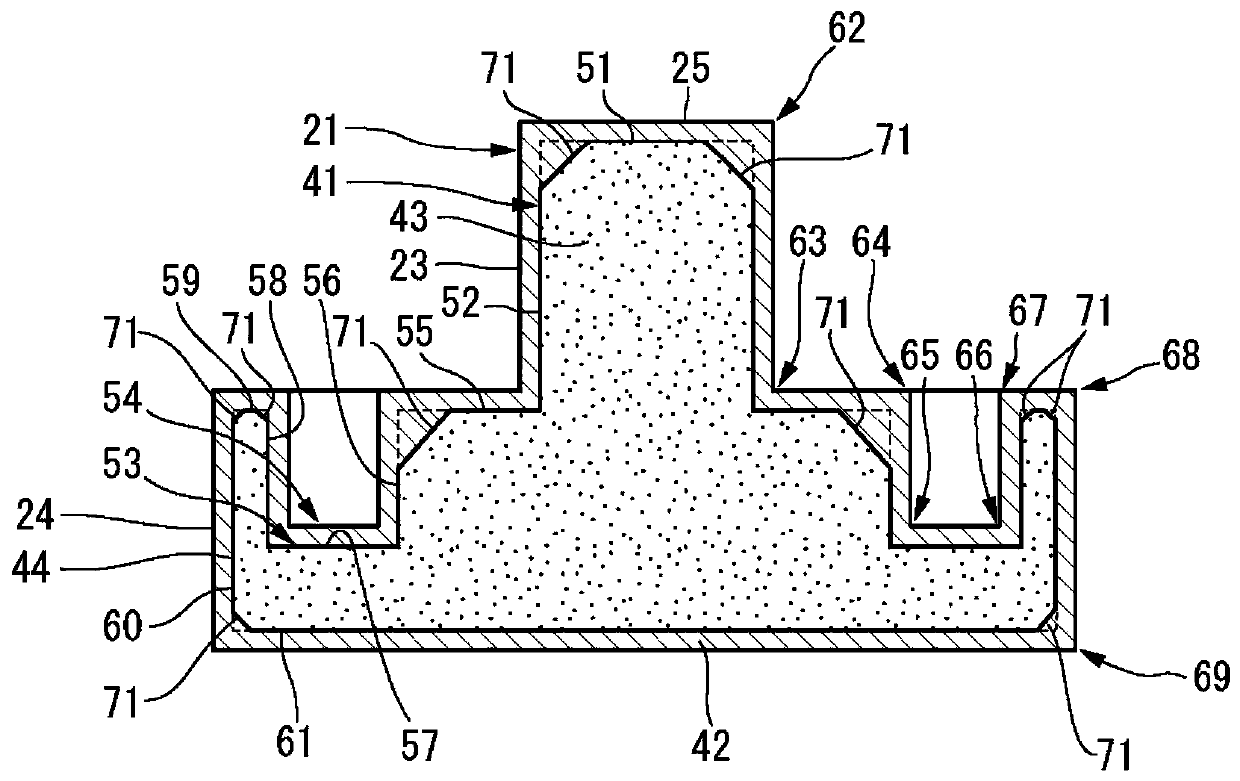

[0066] Slot can be as Figure 6 ~ Figure 8 constructed as shown. exist Figure 6 ~ Figure 8 in, for with Figure 1 to Figure 5 Members that are the same as or equivalent to those described will be given the same reference numerals, and detailed descriptions will be appropriately omitted. The electrode for potential detection of the present embodiment is an example of the electrode for potential detection described in claim 2 .

[0067] The groove 71 in this embodiment extends continuously along the outer surface of the base material 41 from the first end surface 51 at one end in the axial direction of the base material 41 to the fifth end surface 61 at the other end in the axial direction. In detail, the groove 71 extends along the first side surface 52 in the axial direction of the base material 41 to the other end side of the main body portion 21 with one end open on the first end surface 51 of the base material 41 , and radially transversely. Cut the second end surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com