Inclined nuclear power plant transportation channel system and its construction method

A technology for inclined passages and transportation passages, which is used in hoisting devices, buildings, lifting devices, etc., can solve the problems of complex construction procedures, cumbersome installation processes, and long installation periods, and can meet the requirements of high-precision installation and deformation control. , The effect of simplifying the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the drawings and embodiments.

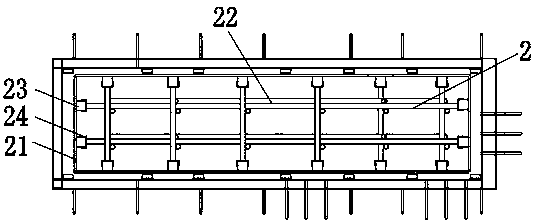

[0035] See Figure 1-5 with Picture 10 , Inclined nuclear power plant transportation channel system, the system includes an inclined channel 1, an inner mold support system 2, a hoop 3, and a positioning device; the inclined channel 1 is composed of a plurality of prefabricated modules, and the prefabricated modules are stainless steel cladding 14 The stainless steel cladding 14 has a channel steel frame 12 and an angle steel frame 13 arranged at intervals, and a stainless steel backing plate 11 is arranged between the stainless steel cladding 14. The two ends of the inclined channel 1 are provided with There is a flange plate 15 which is welded to the channel steel frame 12 of the inclined channel; the inner mold support system 2 is arranged inside the inclined channel 1, and consists of plywood 21, scaffold steel pipe 22, wooden square 23 and adjustment The support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com