Imaging sensor packaging structure and method based on glass substrate

An image sensor and glass substrate technology, which is applied in the direction of electric solid-state devices, semiconductor devices, radiation control devices, etc., can solve the problem of parallelism between the sensing surface of the chip and the glass surface, affect the imaging performance of the CIS chip, and poor heat dissipation performance, etc. problems, to achieve improved thermal management performance, low cost, and good heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with specific drawings and embodiments.

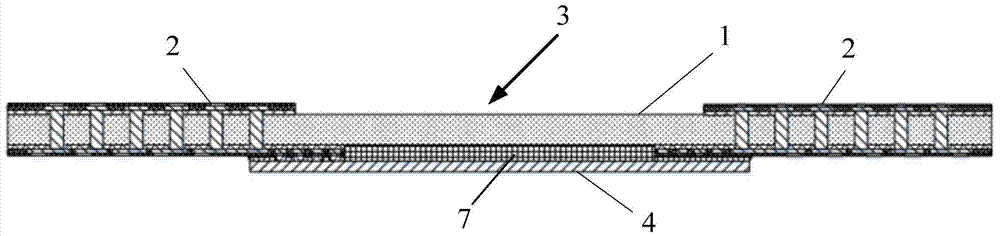

[0035] Such as Figure 1 to Figure 7 Shown: a glass substrate-based image sensor packaging structure, including a transparent glass substrate 1, the front and back of the glass substrate 1 are provided with wiring structures 2 and are electrically connected to each other; the glass substrate 1 has at least one The transparent area 3 without the wiring structure 2, the inverted image sensing chip 4 is mounted on the back of the glass substrate 1, and the sensing surface of the image sensing chip 4 faces the transparent area 3 of the glass substrate 1; the image sensing The chip 4 is electrically connected to the wiring structure 2 outside the transparent area 3 on the back of the glass substrate 1 ; The passive device 5 and the image sensor driver chip 6 are mounted on the front side of the glass substrate 1 other than the transparent area 3 and electrically co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com