Packaging structure and packaging method based on flip-chip image sensor chip

A technology of image sensor and packaging method, which is applied in radiation control devices and other directions, can solve problems such as poor precision of CIS chips, achieve good vibration resistance and reliability, and facilitate heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with specific drawings and embodiments.

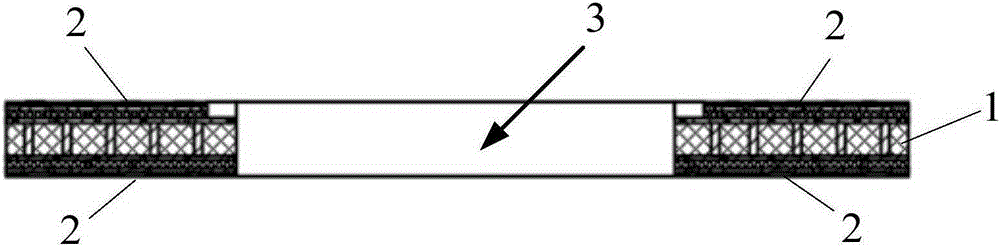

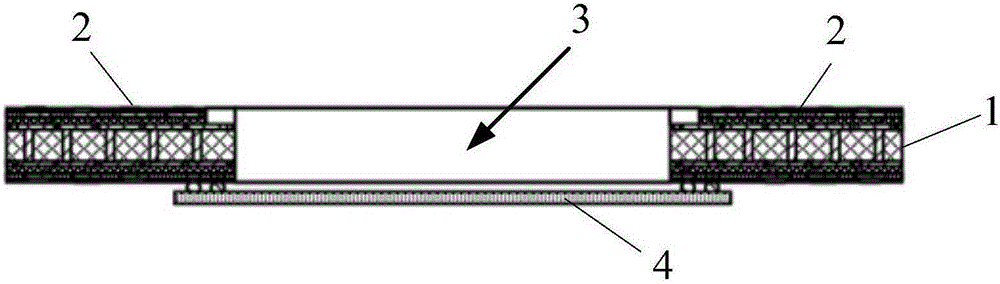

[0035] Such as Figure 1 to Figure 7 Shown: a packaging structure based on a flip-chip image sensor chip, including a substrate 1, a transparent window 3 is opened on the substrate 1, and wiring structures 2 are provided on the front and back of the substrate 1 and are electrically connected to each other; inverted The image sensor chip 4 is mounted on the back of the substrate 1, and the sensing surface of the image sensor chip 4 faces the transparent window 3; the image sensor chip 4 is electrically connected to the wiring structure 2 on the surface; the glass 5 is fixed on the front of the substrate 1 and completely cover the through window 3; the heat sink 10 is bonded to the back of the image sensor chip 4 through the heat dissipation glue 11; the passive device 7 and the image sensor driver chip 8 are mounted on the front side of the substrate 1 other tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com