Preparation method of pressure-resistant washing-resistant super-hydrophobic fabric

A super-hydrophobic fabric technology, applied in animal fibers, plant fibers, textiles and papermaking, etc., can solve the problems of poor stability of super-hydrophobic fabrics and limit the practical application of super-hydrophobic fabrics, and achieve low cost, mild preparation conditions and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] (1) Preparation of pressure-resistant and washable superhydrophobic fabric

[0018] The method for preparing pressure-resistant and washable super-hydrophobic fabrics of the present invention is to disperse methacrylic resin and hydrophobic nanoparticles in a dispersant to form a composite emulsion with a concentration of 5-100 mg / mL, and then coat the composite emulsion by a dip coating method. Cover the surface of fabric fibers, and then heat and cure for 2 to 10 minutes to obtain a pressure-resistant and washable super-hydrophobic fabric.

[0019] Fabrics are polyester, cotton, wool, silk, acrylic, nylon, polyurethane and their blends.

[0020] Its specific preparation method comprises the following process steps:

[0021] (1) Preparation of methacrylic resin: Methyl methacrylate, butyl methacrylate and lauryl methacrylate are added to the aqueous solution that is dissolved with sodium lauryl sulfate and sodium persulfate, in React at 70-90°C for 1-8 hours; cool to...

Embodiment 1

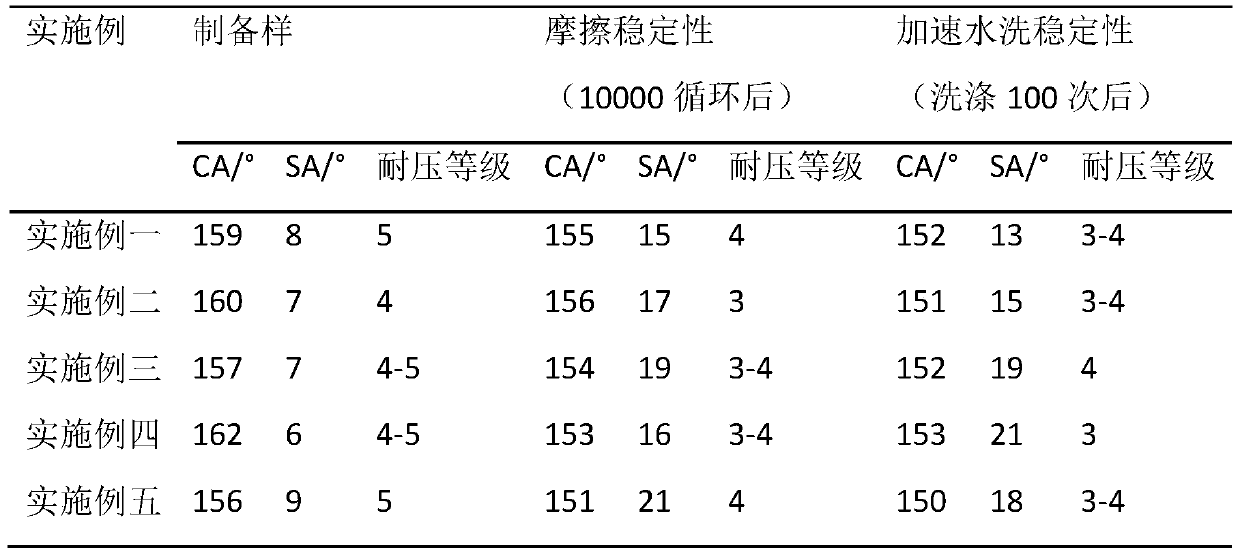

[0037]Weigh 3.2g of methyl methacrylate, 2.6g of butyl methacrylate and 1.2g of dodecyl methacrylate into 80mL aqueous solution dissolved with 1.2g of sodium lauryl sulfate and 0.2g of sodium persulfate , and reacted at 80°C for 2 hours; cooled to room temperature to obtain a crude product; washed, filtered, and vacuum-dried at 50°C to obtain a methacrylic resin. Weigh 1.0 g of methacrylic resin and 0.2 g of hydrophobic silica nanoparticles, and disperse them in 50 mL of ethanol-water (1:1) at high speed to prepare a composite emulsion. Then immerse the 5cm×5cm polyester fabric in the composite emulsion and let it stand for 5 minutes, stirring 2 to 3 times during the period; finally remove the excess composite emulsion in the fabric by pressure filtration, and then heat-cure at 150°C for 3 minutes to obtain the resistant Pressure washable superhydrophobic polyester fabric. The evaluation results of the sample's superhydrophobicity, pressure resistance and stability are shown ...

Embodiment 2

[0039] Weigh 5.0g of methyl methacrylate, 1.2g of butyl methacrylate and 2.3g of dodecyl methacrylate into 120mL aqueous solution dissolved with 3.0g of sodium lauryl sulfate and 0.4g of sodium persulfate , reacted at 80° C. for 4 hours; cooled to room temperature to obtain a crude product; washed, filtered and then vacuum-dried at 50° C. to obtain a methacrylic resin. Weigh 1.0 g of methacrylic resin and 0.1 g of hydrophobic carbon nanotube nanoparticles, and disperse them in 50 mL of ethanol-water (1:1) at high speed to prepare a composite emulsion. Then immerse the 5cm×5cm cotton fabric in the composite emulsion and let it stand for 3 minutes, stirring 2 to 3 times during the period; finally remove the excess composite emulsion in the fabric by pressing filtration, and then heat-cure at 150°C for 4 minutes to obtain the pressure-resistant Washable superhydrophobic polyester fabric. The evaluation results of the sample's superhydrophobicity, pressure resistance and stabilit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com