FeCoNiCrMn high-entropy alloy and method for preparing wear-resisting coating through alloy

A high-entropy alloy and wear-resistant coating technology, applied in the field of engineering science, can solve the problems of high cost of bulk alloys, hindering wide application and high price, and achieve the effects of low cost, improved solubility, and improved friction performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Design the high-entropy alloy composition according to the equiatomic ratio, weigh the original powder with a purity higher than 99.9%, and prepare spherical high-entropy alloy powder by gas atomization.

[0033] 2. Sieve the high-entropy alloy powder prepared by gas atomization, and select the powder with a particle size range of 45-84 mm to ensure good fluidity of the powder during the spraying process, and place the high-entropy alloy powder at 90 Dry at ℃ for 2 hours for later use.

[0034] 3. Choose 304L stainless steel as the substrate, ultrasonically clean the substrate with ethanol to remove oil stains, and roughen the substrate by sandblasting to increase the bonding strength between the coating and the substrate.

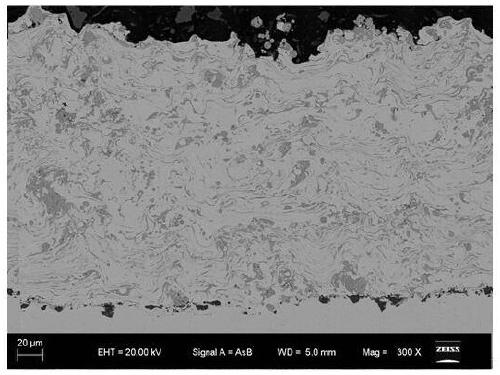

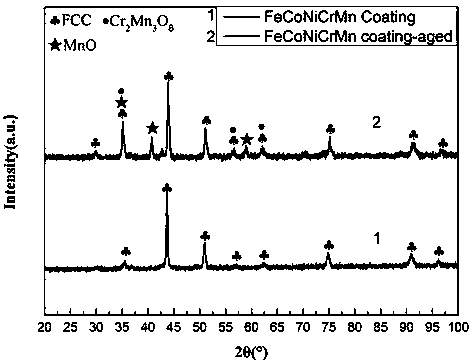

[0035] 4. Using the high-entropy alloy powder prepared above as a raw material, spray it on the surface of the substrate after sandblasting and roughening treatment by atmospheric plasma spraying equipment to obtain a FeCoNiCrMn high-entropy allo...

Embodiment 2

[0041] The differences between this example and Example 1 are: the hydrogen flow rate in step 4 is 5 L / min, the spraying distance is 135 m; the heat treatment temperature in step 5 is 800 °C, and the heat treatment time is 3 h. In step 8, the wear rate of the sprayed FeCoNiCrMn coating was 3.21×10 -4 mm 3 / N m, the coating wear rate after heat treatment is 5.48×10 -5 mm 3 / N·m.

Embodiment 3

[0043] The differences between this example and Example 1 are: the hydrogen flow rate in step 4 is 4 L / min, the spraying distance is 145 mm; the heat treatment temperature in step 5 is 750 °C, and the heat treatment time is 2 h. In step 8, the wear rate of the sprayed FeCoNiCrMn coating was 4.18×10 -4 mm 3 / N m, the coating wear rate after heat treatment is 5.64×10 -5 mm 3 / N·m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com