Pretreatment and leaching method of lepidolite

A lepidolite and pretreatment technology, which is applied in the field of lithium extraction from ores, can solve problems such as inability to carry out industrial operations, low industrial application value, and expensive potassium sulfate, so as to reduce energy consumption for lithium concentration, less impurities, and low production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

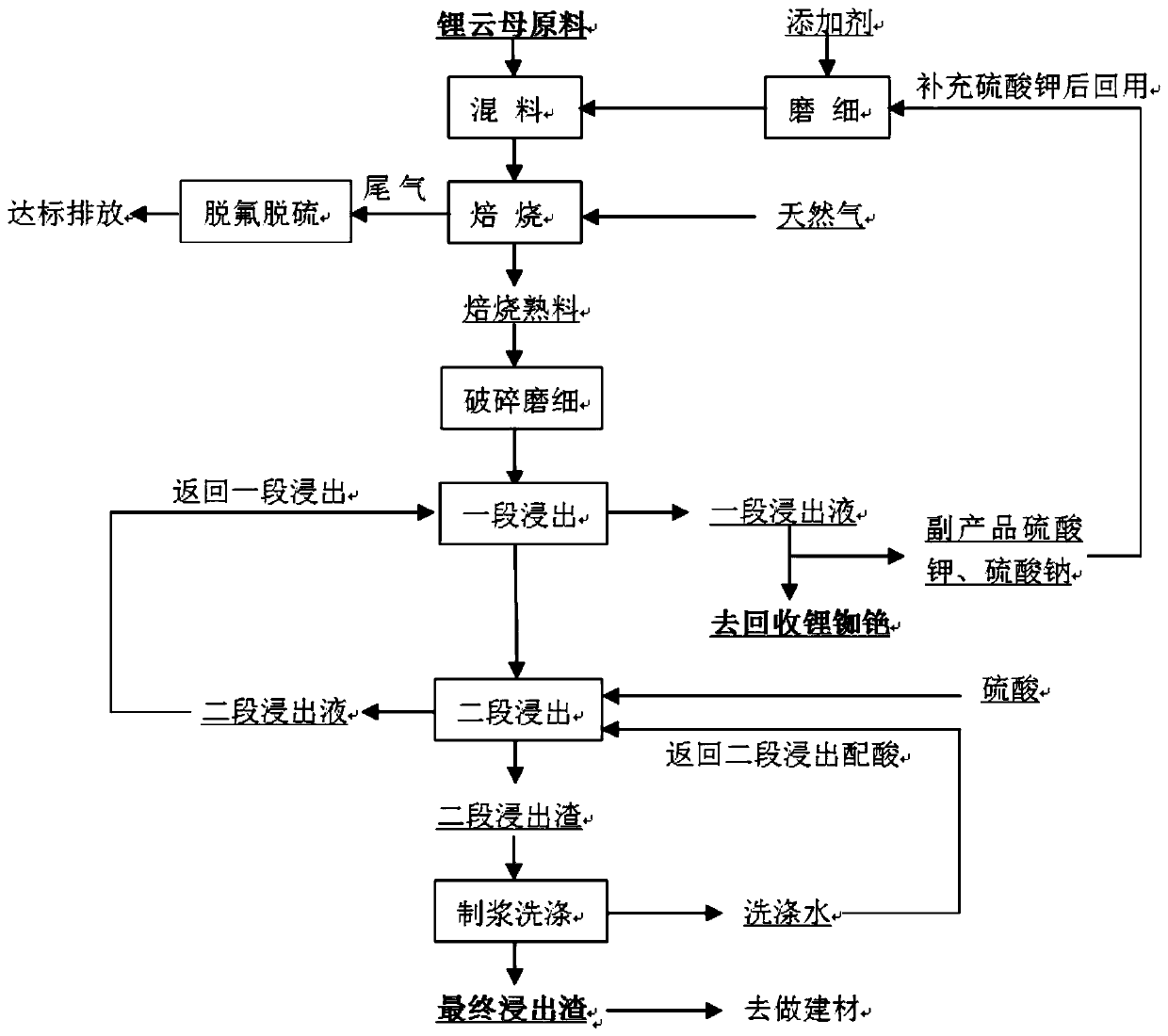

Method used

Image

Examples

Embodiment 1

[0088] Proceed as follows:

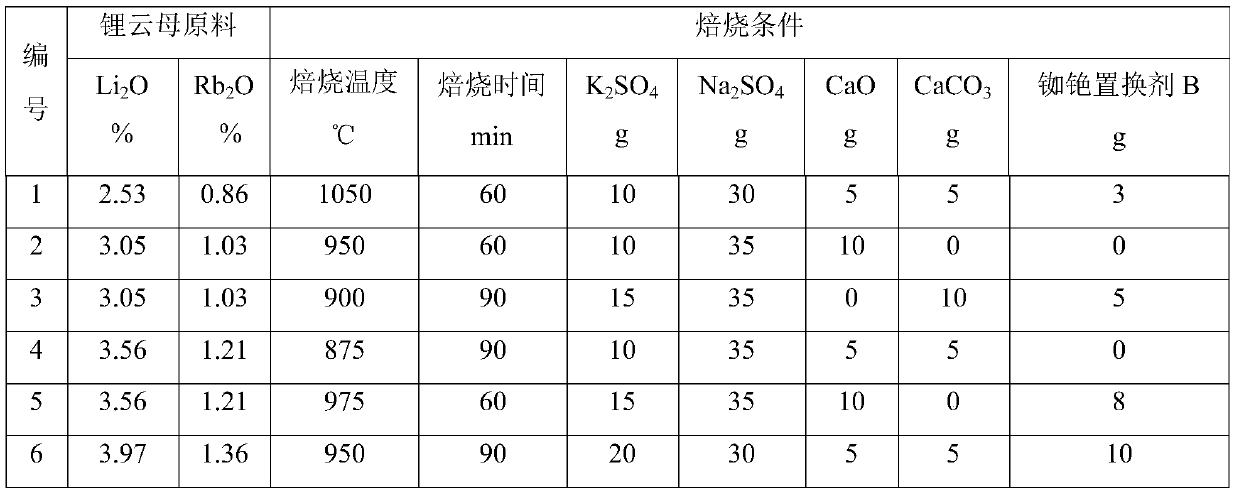

[0089] ① Take 100g lepidolite concentrate and weigh the following reagents: 10g K 2 SO 4 , 30g Na 2 SO 4 , 5g CaO, 5g CaCO 3 , 3g of rubidium and cesium displacer, the reagents are mixed and ground to more than 50% and less than 200 mesh;

[0090] ②Mix the lepidolite concentrate and the finely ground reagent evenly;

[0091] ③Put the mixed material in a crucible and bake at 1050°C for 60 minutes;

[0092] ④ Grind the calcined sand until 85% of it is less than -100 mesh;

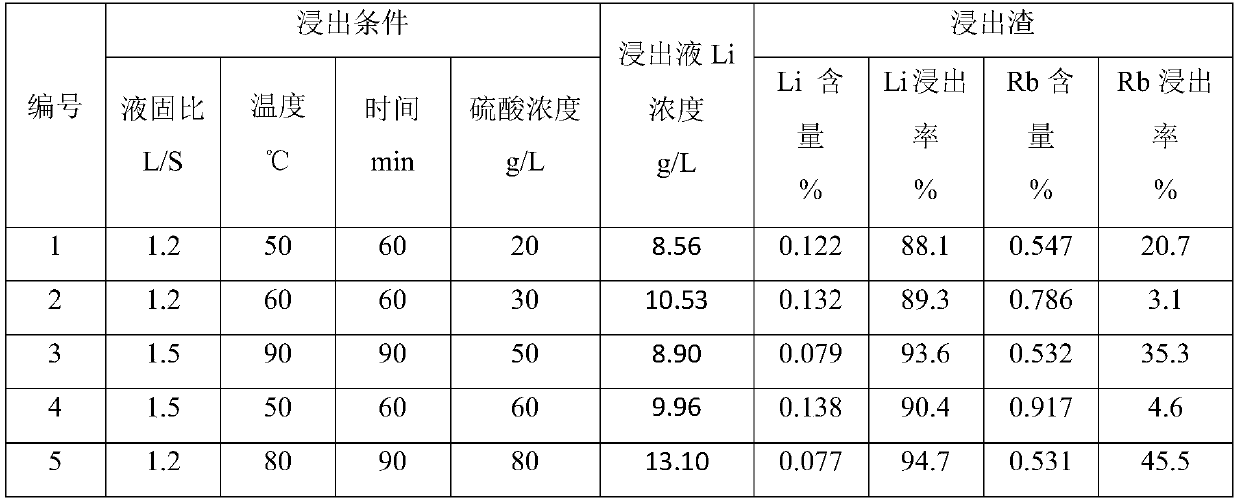

[0093] ⑤Transfer the finely ground calcined sand to the leaching tank for one-stage leaching. The leaching agent used is the second-stage leaching solution obtained from the previous operation under the same conditions. The dosage is 120ml, the temperature is 50°C, and it is stirred for 60 minutes;

[0094] ⑥ For the second-stage leaching, add the washing water and sulfuric acid obtained from the previous operation under the same conditions to the leaching residue of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com