PBAT/starch full biodegradation thin film and preparation method thereof

A technology of butylene adipate and polyterephthalic acid, applied in the field of materials, can solve the problems of reduced material cost, low tensile strength, low tear strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The invention provides a preparation method of polybutylene terephthalate-adipate / starch fully biodegradable film, comprising:

[0045] Mixing starch with a modifier for modification treatment to obtain modified starch;

[0046] Mix and extrude polybutylene terephthalate-adipate resin, modified starch, reinforcing agent, lubricant, and small-molecule plasticizer to obtain the resin for film blowing;

[0047] The blown film is blown with the resin to obtain the polybutylene terephthalate-adipate / starch fully biodegradable film.

[0048] The preparation method of a polybutylene terephthalate-adipate / starch fully biodegradable film provided by the present invention first mixes starch with a modifier for modification treatment to obtain modified starch.

[0049] The weight ratio of starch and modifier in the modified starch is preferably (90-100): (1-3); more preferably (93-100): (1-2.5); most preferably (95-100 ): (1~2); The starch is preferably corn starch.

[0050] Mi...

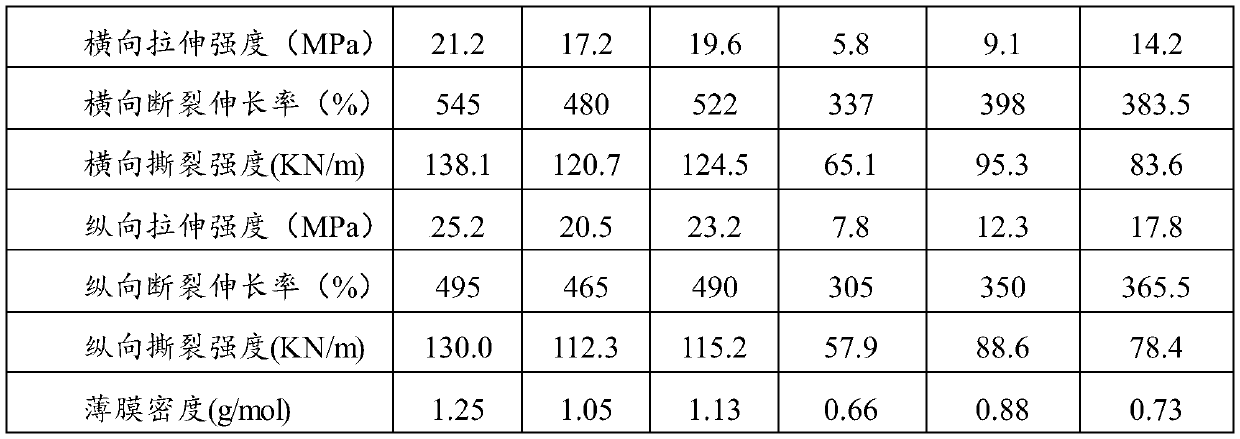

Embodiment 1

[0060] (1) Weigh 98.5 parts of starch, 1 part of maleic anhydride, and 0.5 parts of titanate coupling agent; the order of addition is starch, maleic anhydride, and titanate coupling agent; 90°C, continue to stir for about 3 minutes to discharge, and obtain modified starch;

[0061] (2) Weigh 60 parts of PBAT, 25 parts of modified starch, 10 parts of sorbitol liquid, 5 parts of talcum powder, 1 part of erucamide, and 1 part of ethylene bisstearamide;

[0062] (3) Add each raw material into the high-speed mixer in a certain order, and the order of addition is PBAT, modified starch, talc powder, erucamide, ethylene bisstearamide, and sorbitol liquid; the mixing speed is turned to high speed , high-speed stirring for about 10 minutes to discharge;

[0063] (4) Add the mixed raw materials into the hopper of the twin-screw extruder, set the processing temperature in each temperature zone of the extruder, the operating temperature is 100-180°C, and obtain the PBAT modified resin thr...

Embodiment 2

[0066] (1) Weigh 98.5 parts of starch, 1 part of maleic anhydride, and 0.5 parts of titanate coupling agent; the order of addition is starch, maleic anhydride, and titanate coupling agent; turn the mixing speed to high speed and stir at high speed to 90°C, continue to stir for about 3 minutes to discharge, and obtain modified starch;

[0067] (2) Weigh 55 parts of PBAT, 35 parts of modified starch, 10 parts of sorbitol, 0.5 part of erucamide, and 0.5 part of ethylene bis-stearamide;

[0068] (3) Add the raw materials into the high-speed mixer in a certain order, and the order of addition is PBAT, starch, erucamide, ethylene bisstearamide, and sorbitol; turn the mixing speed to high speed, and stir at high speed for about 10 minutes ready to discharge;

[0069] (4) Add the mixed raw materials into the hopper of the twin-screw extruder, set the processing temperature in each temperature zone of the extruder, the operating temperature is 100-180°C, and obtain the PBAT modified r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com