Method for manufacturing inert coating layer on surface of ceramic core

A technology for ceramic cores and manufacturing methods, which is applied in cores, manufacturing tools, casting molds, etc., and can solve the problem of poor high-temperature chemical stability of silicon oxide ceramic cores, absence of alumina-based ceramic cores, and alumina-based ceramic cores. Get rid of problems such as difficulties, achieve huge economic value and social value, not easy to crack, and eliminate the effect of reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A method for manufacturing an inert coating layer on the surface of a ceramic core, which coats the surface of a silicon-based ceramic core with an inert layer, avoids direct contact between the core and a high-temperature alloy to cause thermochemical reactions, and solves the problem of the reaction between the core and the alloy.

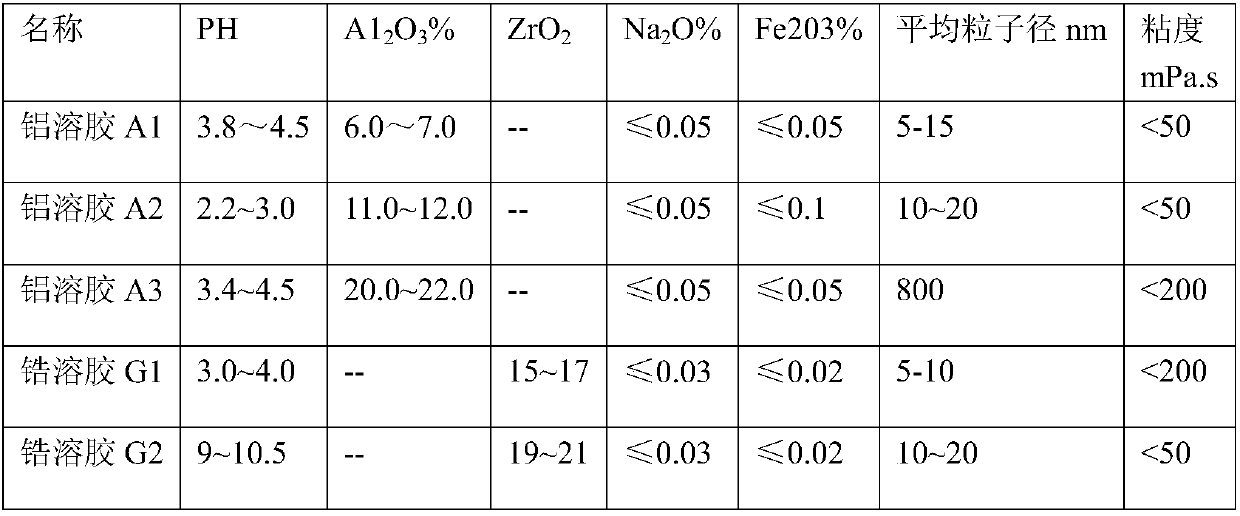

[0051] The inert layer coated on the surface of the silicon-based ceramic core meets the following requirements: aluminum sol and zirconium sol are selected as the coating agent. The models and performance indicators of aluminum sol and zirconium sol meet the requirements of Table 1:

[0052] Table 1 Models and performance indicators of aluminum sol and zirconium sol

[0053]

[0054] Specifically, a combination of aluminum sol A1, aluminum sol A2, aluminum sol A3, zirconium sol G1, and zirconium sol G2 is selected.

[0055] The typical application scheme of the manufacturing method of the inert coating layer on the surface of the cera...

Embodiment 2

[0069] The content of this embodiment is basically the same as that of Embodiment 1, and its difference mainly lies in:

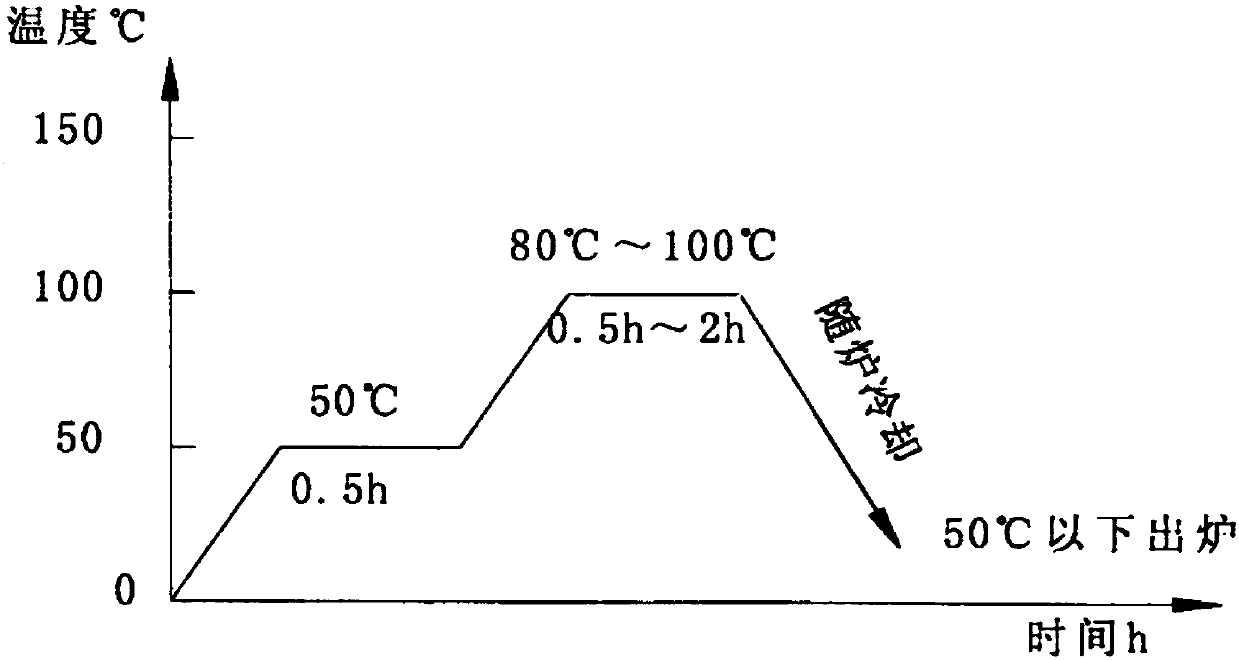

[0070] The baking process curve requirements are as follows (such as figure 1 shown):

[0071] First raise the temperature to 40-70°C, bake for 0.2-1h, then raise the temperature to 70-120°C, and dry for 0.5-2h; then cool down to below 50°C with the furnace and leave the oven.

Embodiment 3

[0073] A method for manufacturing an inert coating layer on the surface of a ceramic core, which coats the surface of a silicon-based ceramic core with an inert layer, avoids direct contact between the core and a high-temperature alloy to cause thermochemical reactions, and solves the problem of the reaction between the core and the alloy.

[0074] The inert layer coated on the surface of the silicon-based ceramic core meets the following requirements: aluminum sol and zirconium sol are selected as the coating agent. The models and performance indicators of aluminum sol and zirconium sol meet the requirements of Table 1:

[0075] Table 1 Models and performance indicators of aluminum sol and zirconium sol

[0076]

[0077] Specifically, a combination of aluminum sol A1, aluminum sol A2, aluminum sol A3, zirconium sol G1, and zirconium sol G2 is selected.

[0078] The typical application scheme of the manufacturing method of the inert coating layer on the surface of the cera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com