Method for mediating albumin to form protein layer on material surface, biomaterial and application thereof

A biomaterial, albumin technology, applied in the preparation method of albumin peptide, serum albumin, peptide, etc., can solve the problem that the biocompatibility of titanium and titanium alloy does not meet the clinical requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

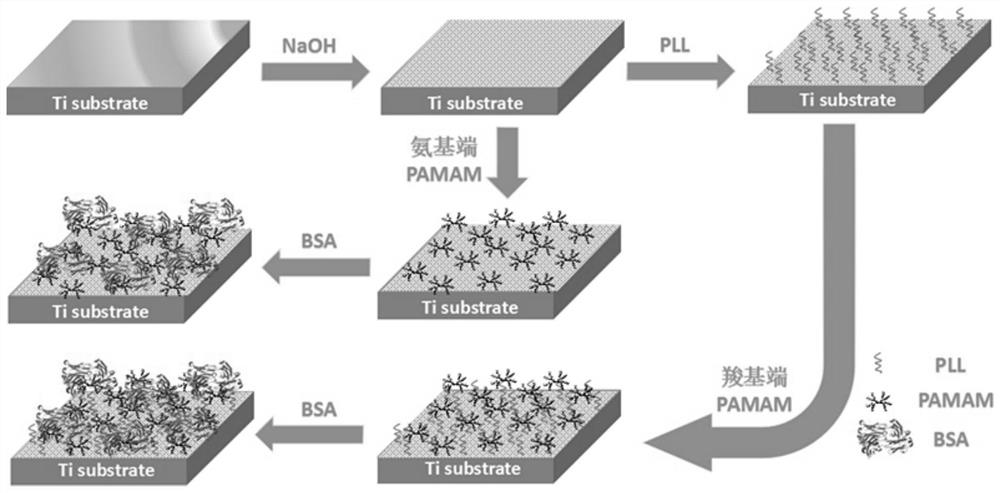

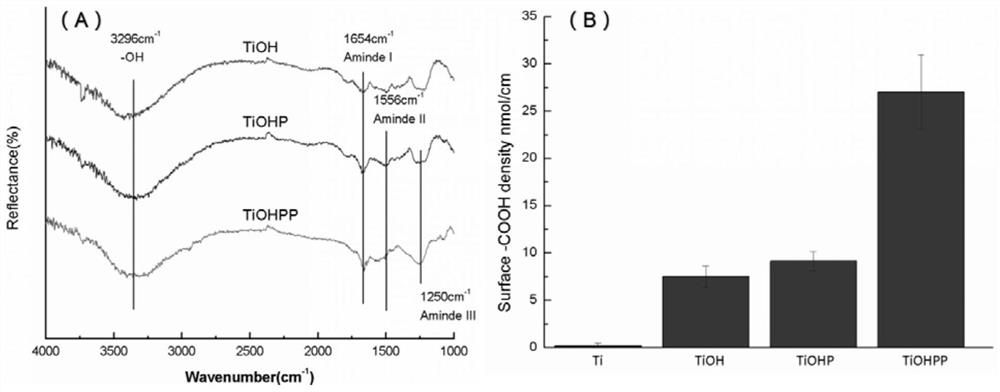

[0050] This embodiment provides a method for mediating albumin to form a protein layer on the surface of a material, which includes the following steps:

[0051] (1) Alkali activation. After cleaning the surface of pure titanium, it is immersed in 2.5mol / L NaOH solution and reacted for 8 hours. Then, after ultrasonic cleaning with RO water, immerse in UP water, let stand at 80°C for 8 hours, ultrasonically clean with UP water, and dry for later use.

[0052] (2) Surface amination. Submerge the alkali-activated sample in a poly-L-lysine solution with a concentration of 2 mg / mL (poly-L-lysine with an average molecular weight of about 150 KDa is dissolved in a phosphate buffer with pH=7), and the reaction 8h, and then washed 3 times with phosphate buffered saline and stored for later use.

[0053] (3) Covalent immobilization of PAMAM. Use PAMAM with a molecular weight of about 1000 (carboxyl at the end) to configure a 0.5 mg / mL dendrimer solution, add carboxyl activator dichl...

Embodiment 2

[0056] This embodiment provides a method for mediating albumin to form a protein layer on the surface of a material, which includes the following steps:

[0057] (1) Alkali activation. After cleaning the surface of pure titanium, it is immersed in 3.5mol / L NaOH solution and reacted for 12 hours. Then, after ultrasonic cleaning with RO water, immerse in UP water, let stand at 90°C for 12 hours, ultrasonically clean with UP water, and dry for later use.

[0058] (2) Surface amination. Submerge the alkali-activated sample in a poly-L-lysine solution with a concentration of 3 mg / mL (poly-L-lysine with an average molecular weight of about 300 KDa is dissolved in a phosphate buffer solution of pH=8), and the reaction 12h, and then washed 3 times with phosphate buffered saline, and then stored for future use.

[0059] (3) Covalent immobilization of PAMAM. Use PAMAM with a molecular weight of about 100,000 (carboxyl at the end) to configure a 10 mg / mL dendrimer solution, add carbo...

Embodiment 3

[0062] This embodiment provides a method for mediating albumin to form a protein layer on the surface of a material, which includes the following steps:

[0063] (1) Alkali activation. After cleaning the surface of pure titanium, it is immersed in 3mol / L NaOH solution and reacted for 10 hours. Then, after ultrasonic cleaning with RO water, immerse in UP water, let stand at 85°C for 10 hours, ultrasonically clean with UP water, and then dry for use.

[0064] (2) Surface amination. Submerge the alkali-activated sample in a poly-L-lysine solution with a concentration of 2.5 mg / mL (poly-L-lysine with an average molecular weight of about 200 KDa is dissolved in a phosphate buffer with pH=7.4), React for 10 h, then wash with phosphate buffered saline for 3 times and store for future use.

[0065] (3) Covalent immobilization of PAMAM. Use PAMAM with a molecular weight of about 9000 (carboxyl at the end) to configure a 1 mg / mL dendrimer solution, add carboxyl activator N-hydroxysu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com