Special fixture for aluminum profiles and use method

A special fixture and aluminum profile technology, which is applied in the field of aluminum profile manufacturing, can solve the problems of pollution sources, material waste of aluminum profiles, copper fixture dissolution and damage, etc., and achieve the effect of excellent electrical conductivity and good clamping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

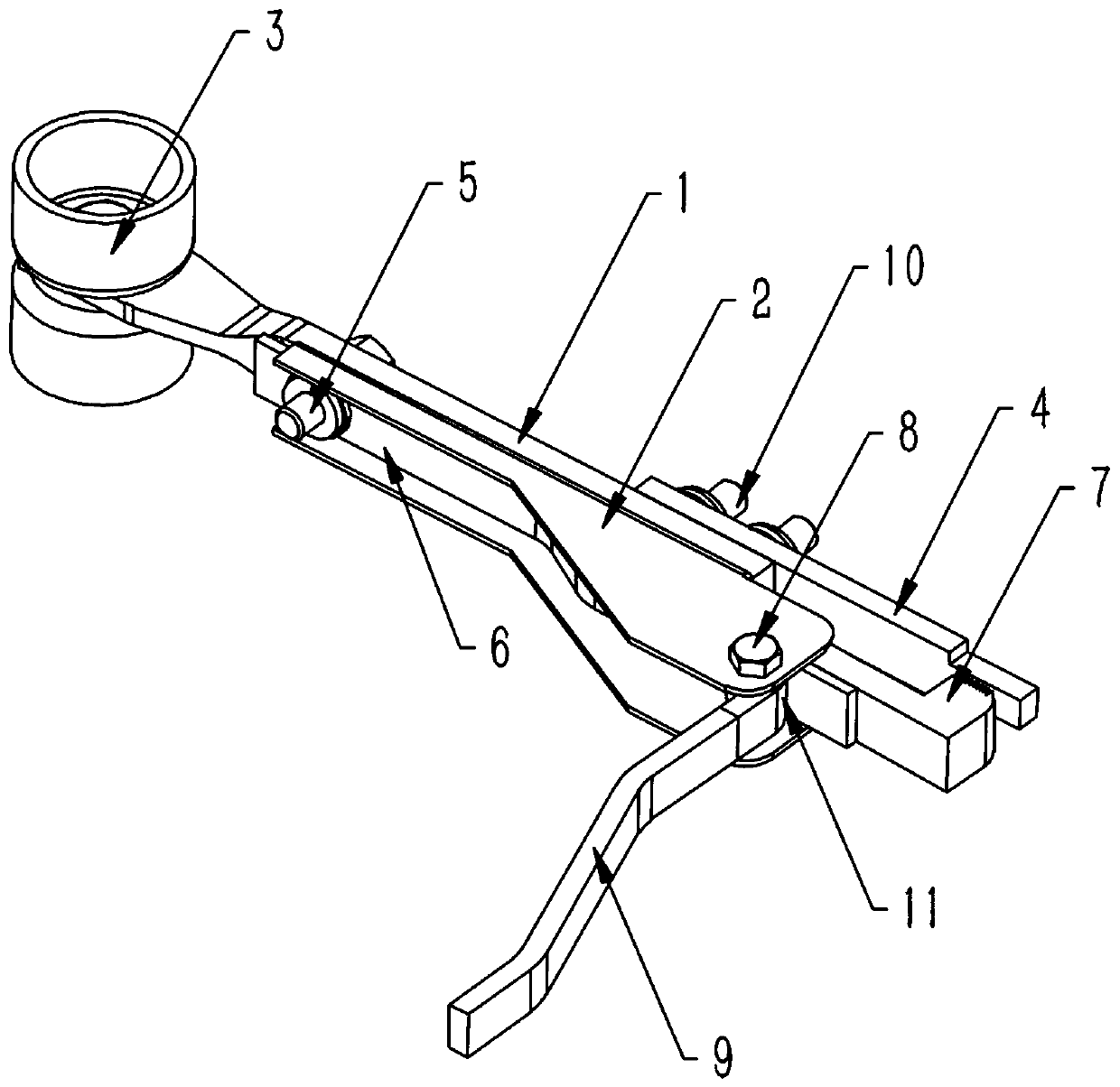

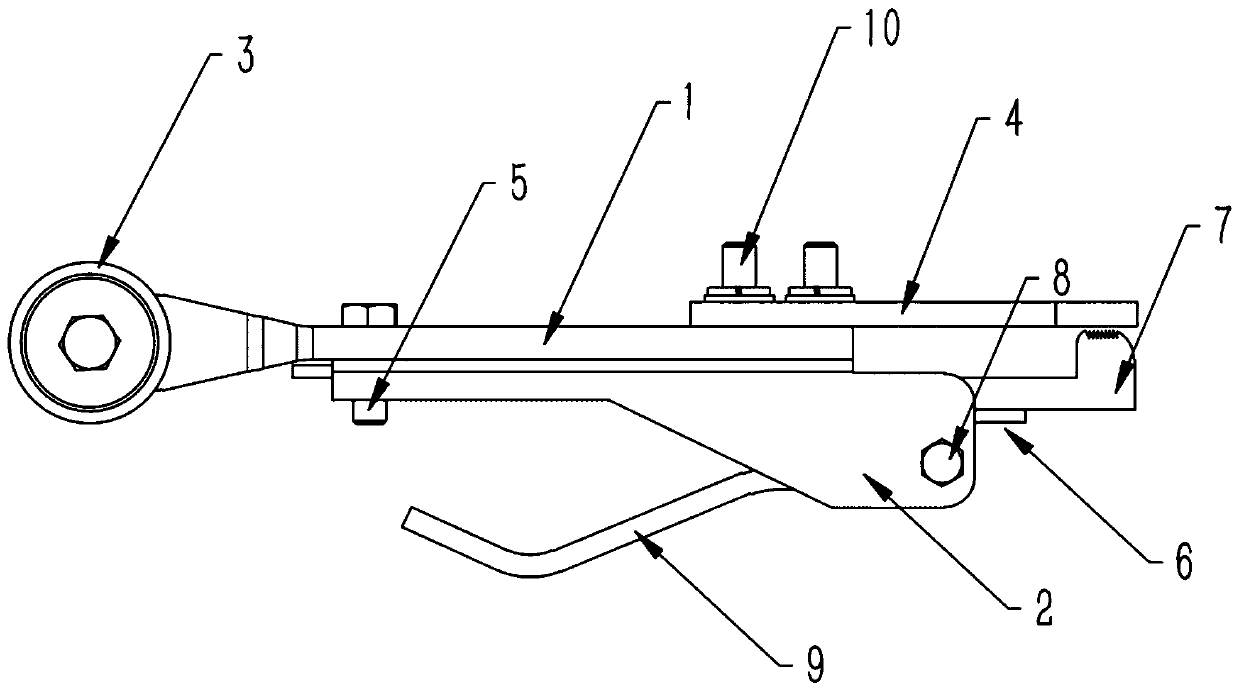

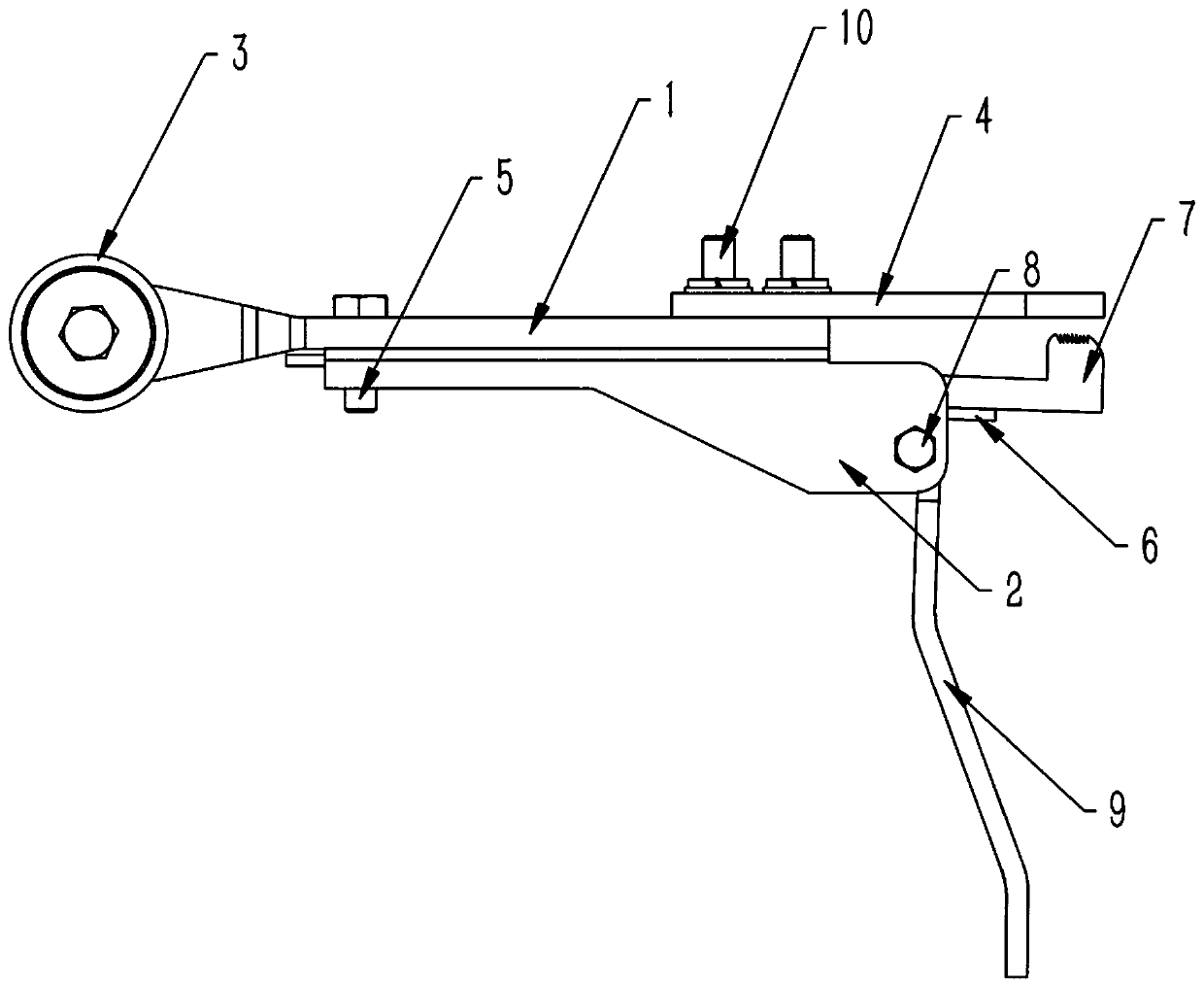

[0021] In conjunction with the accompanying drawings, a special fixture for aluminum profiles is characterized in that it includes a fixture body 1 and a support 2, the support 2 is a groove-shaped structure, the support 2 is located at the bottom of the fixture body 1, and the fixture body 1 There is a bowl-shaped fixing part 3 on both sides of one end, and a stopper 4 is arranged on the top of the other end. The stopper 4, the clamp body 1 and the bowl-shaped fixing part 3 are all made of copper material, and the outer surface of the stopper 4 is covered with Titanium alloy thin plate (titanium alloy thin plate is not covered at the joint with the fixture body 1), one end in the groove of the support member 2 is fixed to the fixture body 1 and the elastic bending plate 6 through the bolt and nut assembly 5, and the other end in the groove is fixed through the bolt and nut The assembly 10 is fixed with the fixture main body 1 and the stopper 4, and the end of the elastic bent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com