Preparation method of trench MOSFET integrating Schottky diode

A technology of Schottky diodes and trenches, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of asymmetric sidewall technology, which is difficult to realize, large forward conduction loss recovery current, and low product yield. , to achieve the effect of improving device performance, improving yield level, and reducing manufacturing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

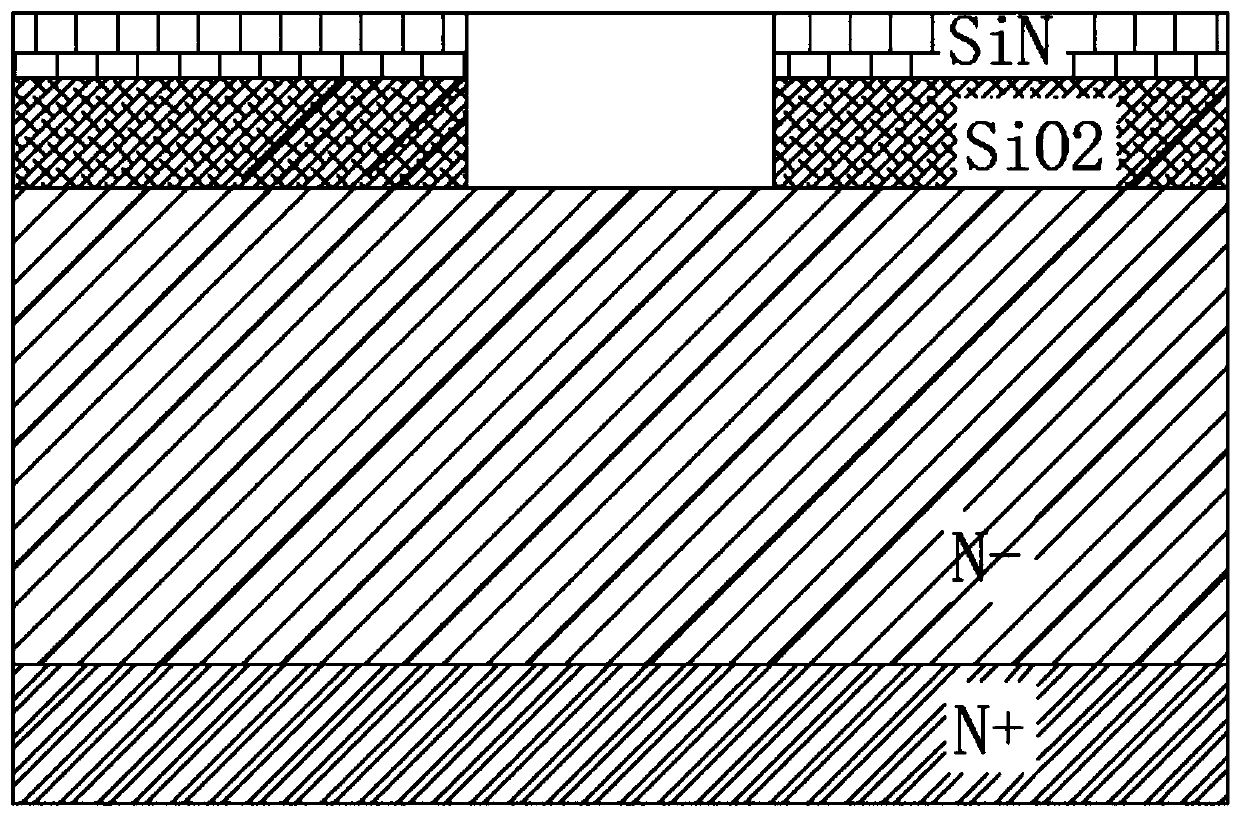

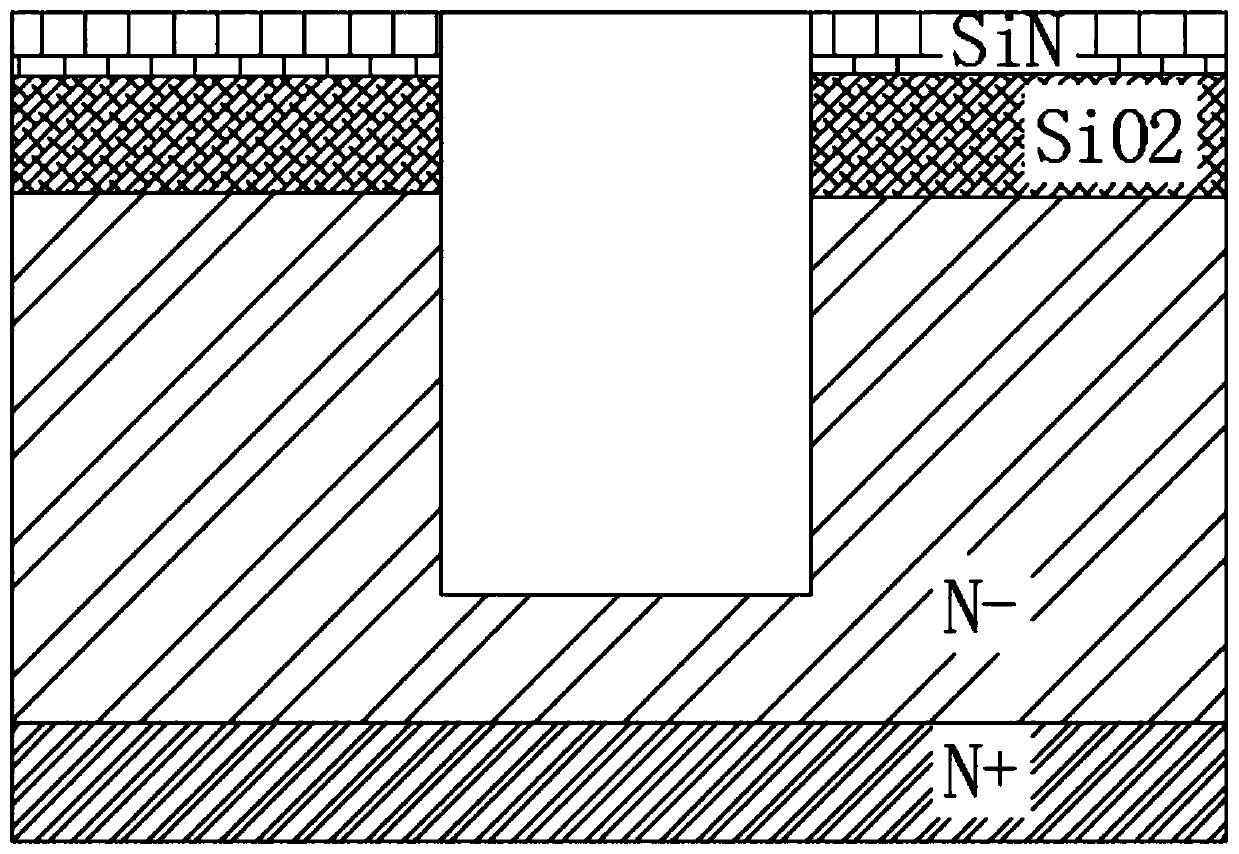

[0025] The present invention is explained by taking N-channel devices as an example, and P-channel devices can also be prepared by a similar process. figure 1 In this case, the N-type substrate 101 (N- epitaxial layer grown on the N++ substrate) is used as the drain of the device. In this example, the doping concentration of the epitaxial layer is 5.15×10 15 / cm 3 , the thickness is 7um.

[0026] S1: combine figure 1 , a silicon dioxide layer is formed on the N-region by deposition or thermal oxidation, and a silicon nitride layer is deposited on top of the silicon dioxide layer. In this example, the thickness of the silicon dioxide layer is The thickness of the silicon nitride layer is The oxide layer needs to have a certain thickness to prevent contamination of the source region during the subsequent preparation of the Schottky region.

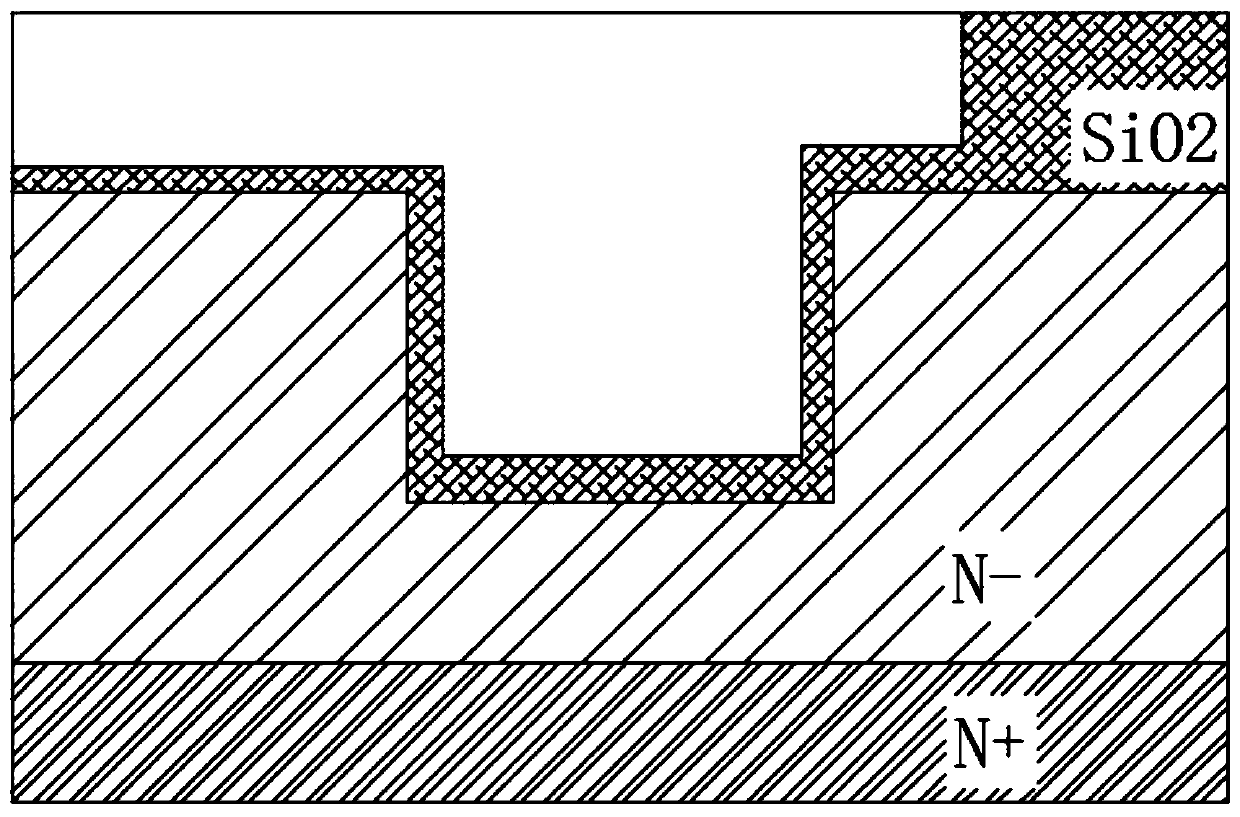

[0027] S2: combine figure 2 , apply photoresist on the silicon nitride layer, and use the first layer of mask plate, using the char...

Embodiment 2

[0036] The present invention is explained by taking N-channel devices as an example, and P-channel devices can also be prepared by a similar process. figure 1 In this case, the N-type substrate 101 (N- epitaxial layer grown on the N++ substrate) is used as the drain of the device. In this example, the doping concentration of the epitaxial layer is 5.15×10 15 / cm 3 , the thickness is 7um.

[0037] S1: combine figure 1 , a silicon dioxide layer is formed on the N-region by deposition or thermal oxidation, and a silicon nitride layer is deposited on top of the silicon dioxide layer. In this example, the thickness of the silicon dioxide layer is The thickness of the silicon nitride layer is The oxide layer needs to have a certain thickness to prevent contamination of the source region during the subsequent preparation of the Schottky region.

[0038] S2: combine figure 2 , apply photoresist on the silicon nitride layer, and use the first layer of mask plate, using the char...

Embodiment 3

[0047] The present invention is explained by taking N-channel devices as an example, and P-channel devices can also be prepared by a similar process. figure 1 In this case, the N-type substrate 101 (N- epitaxial layer grown on the N++ substrate) is used as the drain of the device. In this example, the doping concentration of the epitaxial layer is 5.15×10 15 / cm 3 , the thickness is 7um.

[0048] S1: combine figure 1 , a silicon dioxide layer is formed on the N-region by deposition or thermal oxidation, and a silicon nitride layer is deposited on top of the silicon dioxide layer. In this example, the thickness of the silicon dioxide layer is The thickness of the silicon nitride layer is The oxide layer needs to have a certain thickness to prevent contamination of the source region during the subsequent preparation of the Schottky region.

[0049] S2: combine figure 2 , apply photoresist on the silicon nitride layer, and use the first layer of mask plate, using the char...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com