Method for increasing crude oil recovery ratio through modifying, flooding and washing alternate injection

A technology of alternate injection and recovery, applied in chemical instruments and methods, production fluids, earthwork drilling, etc., can solve the problems of difficult cleaning, limited recovery, and difficult injection, and achieve low cumulative output concentration, Delaying the output time and realizing the effect of cost reduction and efficiency increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

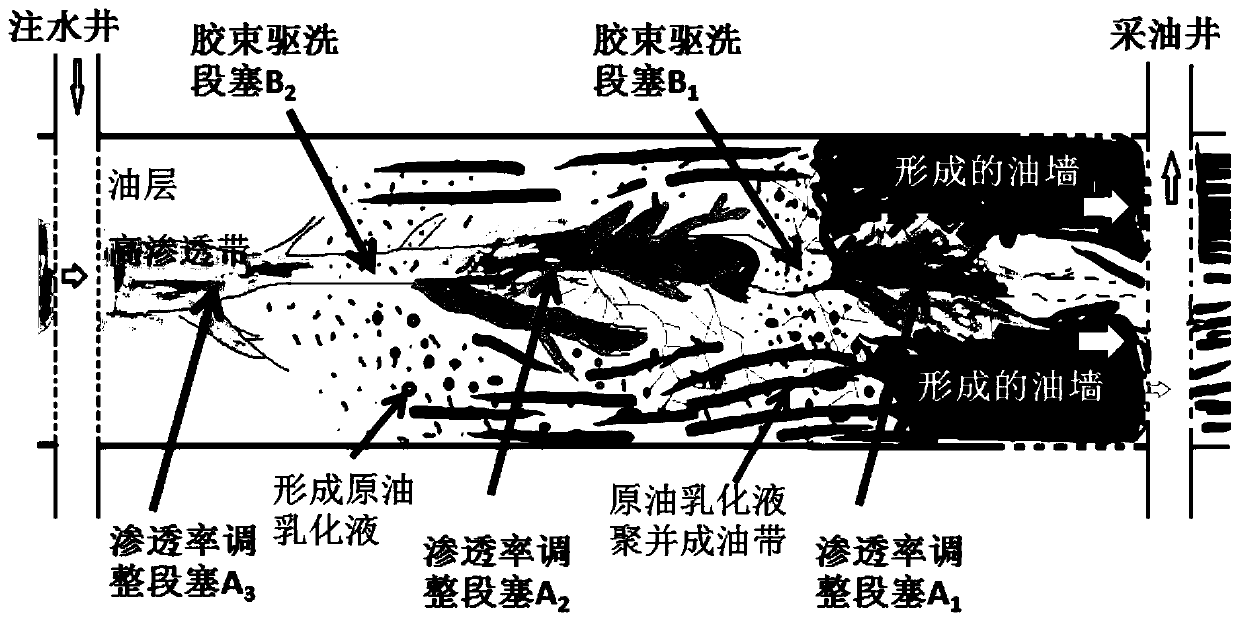

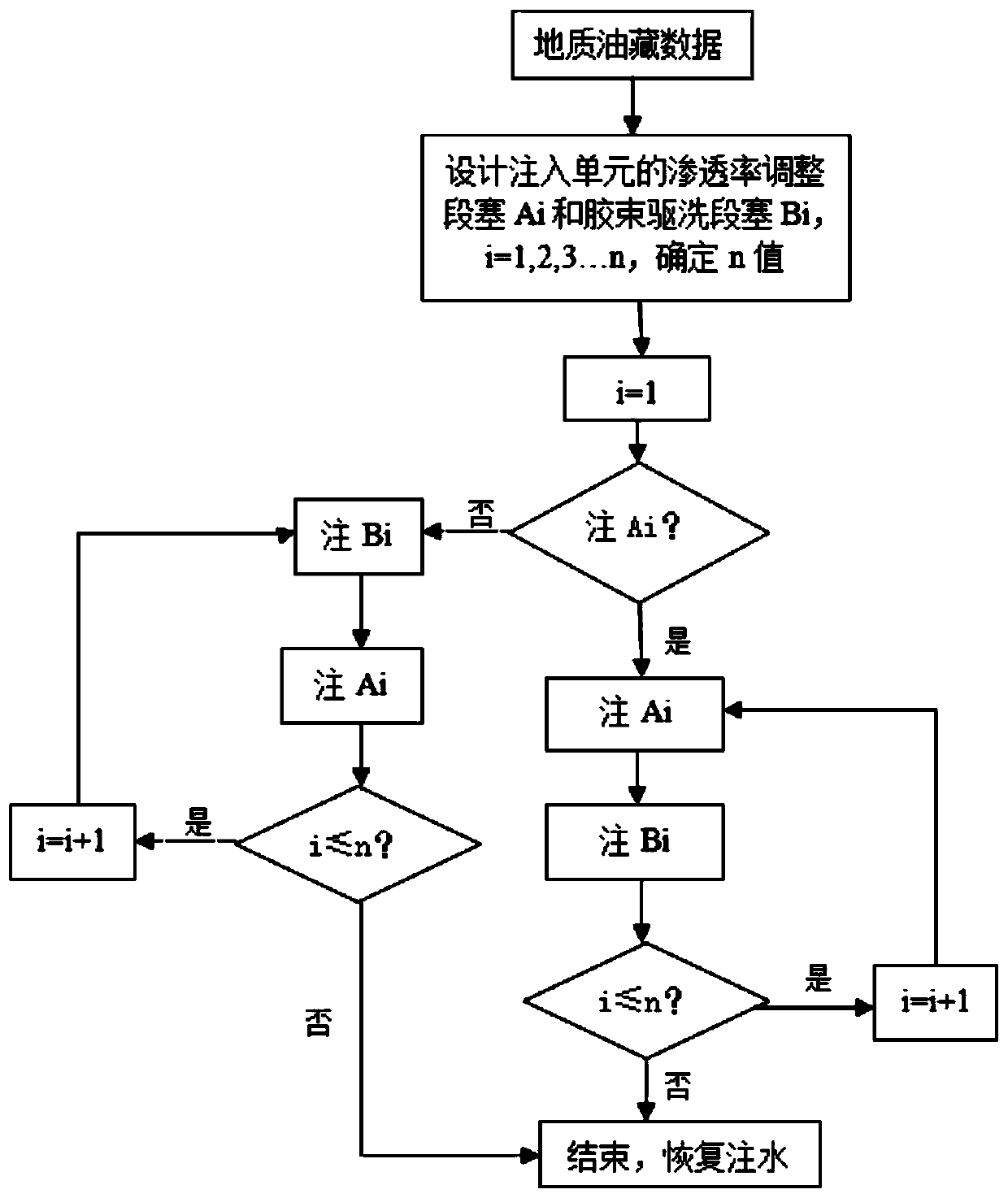

Method used

Image

Examples

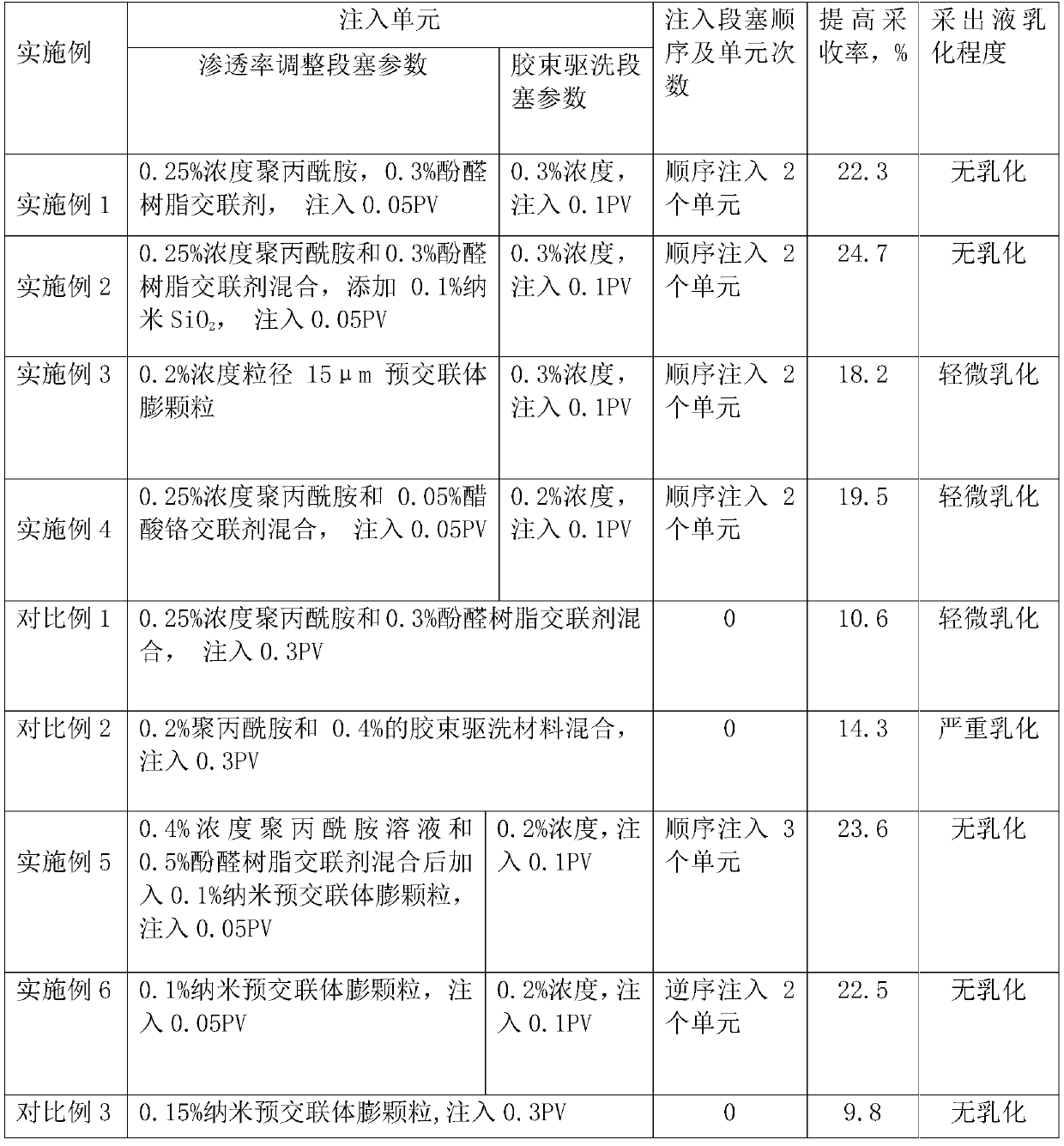

Embodiment 1

[0043] Target reservoir 1: The permeability of QHD32-6 reservoir is 50-18000mD, the reservoir temperature is about 65℃, the salinity is about 10000mg / L, the comprehensive water content of the block is more than 90%, the crude oil recovery degree is about 18%, and water flooding exists Advantageous channel, low water flooding efficiency.

[0044] Flood saturated oil cores with water to 98% water content, prepare a polyacrylamide solution with a mass percentage of 0.2% of the molecular weight of 17 million and a degree of hydrolysis of 25% with injected water, add 0.3% of the mass percentage of phenolic resin cross-linking agent, and mix the permeability adjustment material t 1, inject 0.05PV core of simulated reservoir permeability, wait for 48 hours to complete the permeability adjustment slug A 1 ; Prepare 0.3% micellar flushing material s by injecting water 1 Continue to inject 0.1PV to complete the micelles flushing slug B 1 , complete one injection unit, and repeat 2 inj...

Embodiment 2

[0046] According to the method of Example 1, the difference is that the permeability regulator t 1 Adding 0.1% by mass percentage of nano-SiO 2 , and the results are shown in Table 1.

Embodiment 3

[0048] According to the method of Example 1, the difference is that the permeability regulator t 1 Table 1 shows the results of enhanced oil recovery by replacing the pre-crosslinked expanded particles with a mass percentage of 0.2% and an average particle size of 15 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com