Closing device for grout inlet of steel bar connecting sleeve for fabricated structure

A technology for connecting sleeves and closing devices of steel bars, which is applied to structural elements, building components, building structures, etc., can solve problems such as affecting the compactness of sleeves, and achieve the goal of reducing grouting leakage, reducing grouting material waste, and reducing plugging failures. possible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

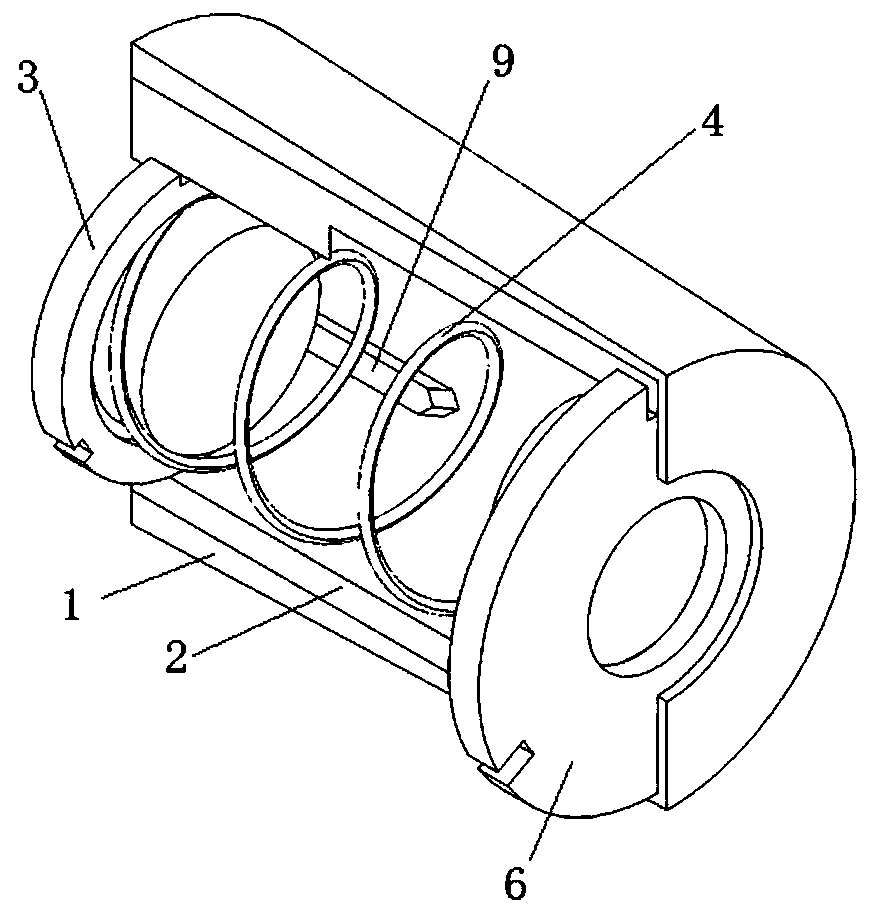

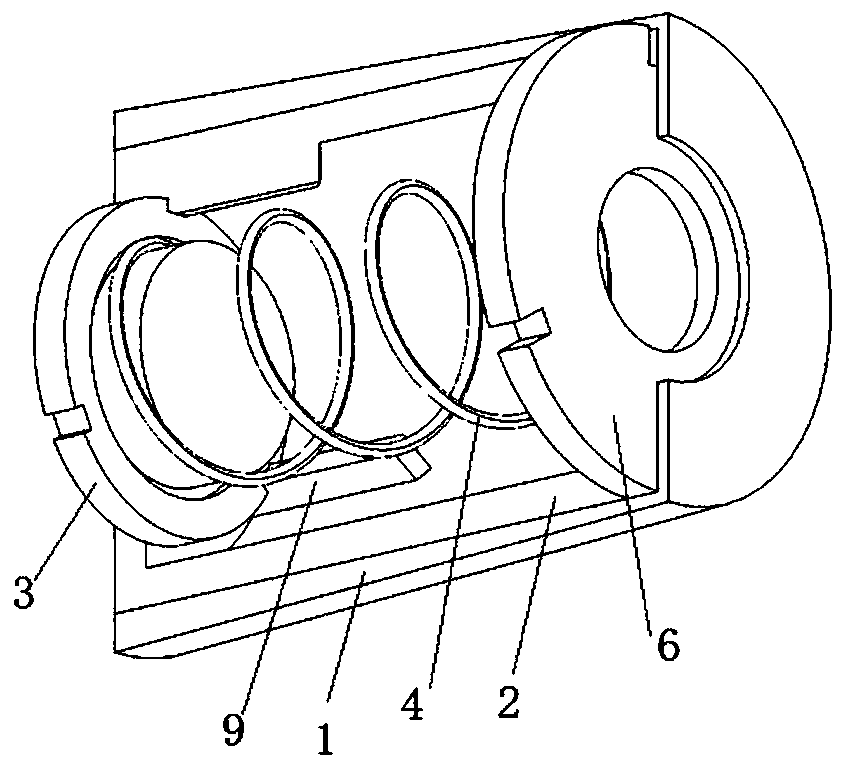

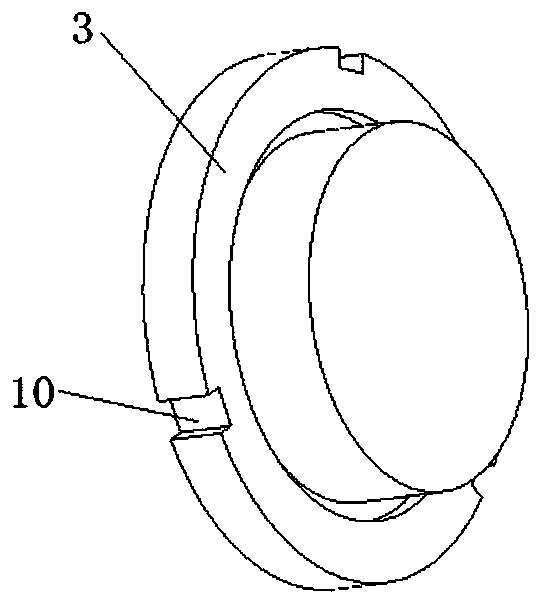

[0023] Such as Figure 1-6 As shown, the present invention provides a closed device for the slurry inlet of an assembled structural steel bar connection sleeve, including a seal 1, a hard tube 2, a sliding baffle 3 and a spring 4, the seal 1 is in the shape of a cone, and the center A through hole is opened; the hard tube 2 is cylindrical and is fixed in the through hole of the seal 1, the side close to the seal 1 with a large diameter is the front end, and the side close to the seal 1 with a small diameter One end is the rear end; the sliding baffle 3 is arranged on the front end of the hard pipe 2, and the diameter is smaller than the inner diameter of the hard pipe 2, so that the slurry can flow from the inner wall of the hard pipe 2 and the outer wall of the sliding baffle 3 One end of the spring 4 is connected with the sliding baffle 3 , and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com