Blue light CdSe nanosheet crystal form regulation and control method

A technology of crystal form control and nanosheets, which is applied in nanotechnology, nano-optics, nanotechnology, etc., can solve the problems of incompatibility, differences in synthesis methods, and inability to synthesize at the same time, and achieve long storage time, narrow half-peak width, and centrifugation. The effect of easy purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

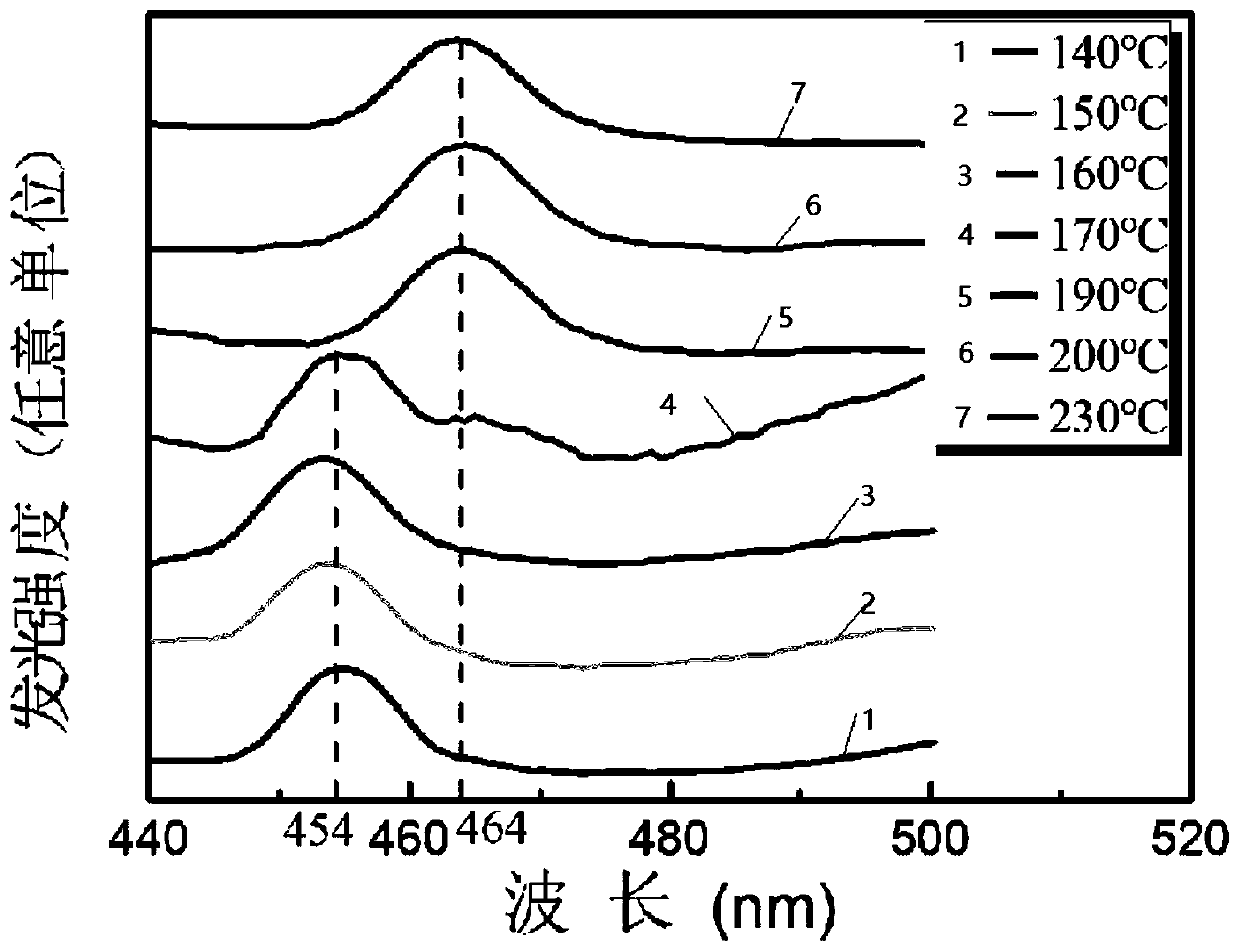

[0016] Step 1, dissolve 0.9mmol cadmium acetate dihydrate and 0.15mmol selenium powder in 30ml polar solvent ODE, then add 0.15mml oleic acid, mix well, and heat up to 140°C, 150°C and 160°C under the protection of inert gas ℃, react for 1h, and cool to obtain blue-light hexagonal wurtzite CdSe nanosheets;

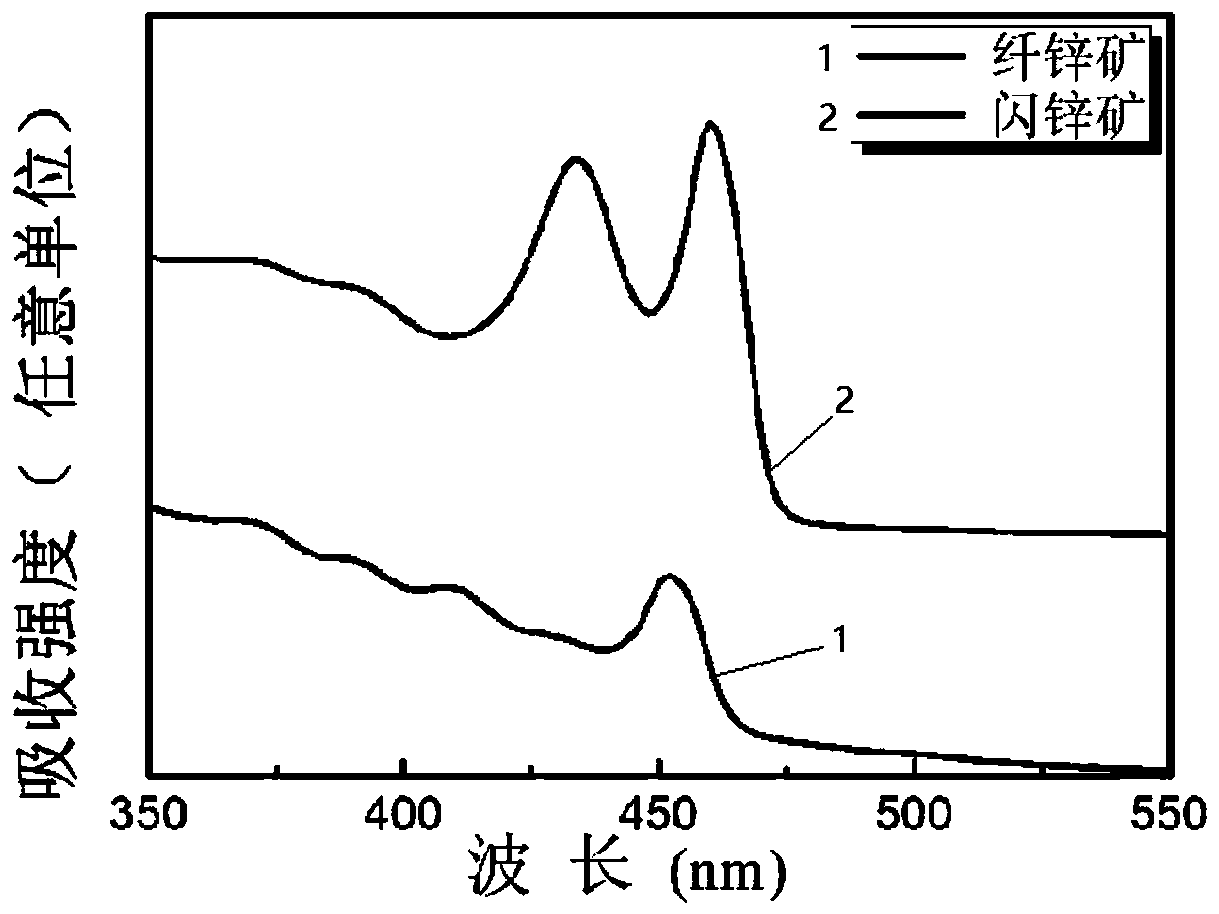

[0017] Step 2, mix the wurtzite CdSe nanosheet solution with ethanol and hexane at a volume ratio of 1:1:3, and centrifuge at a speed of 8000r / min, pour off the supernatant after centrifugation, and repeat the centrifugation for 2-4 times. The purer CdSe nanosheets were obtained, and then dispersed into n-hexane for storage. See the test results figure 1 , image 3 and Figure 4 , indicating that the nanosheets with wurtzite structure are all synthesized at the temperature between 140-160°C, and the emission peaks are all around 454nm.

Embodiment 2

[0019] This example is the same as Example 1, except that the reaction temperature in Example 1 is changed from 140°C to 170°C, and the reaction time is changed from 1h to 3min. See the test results figure 1 and image 3 , it can be seen that at the reaction temperature of 170°C, the emission spectrum of the nanosheets has two peaks, one at 454nm and one at 465nm. It shows that the solution contains both face-centered cubic sphalerite structure nanosheets and hexagonal wurtzite structure nanosheets.

Embodiment 3

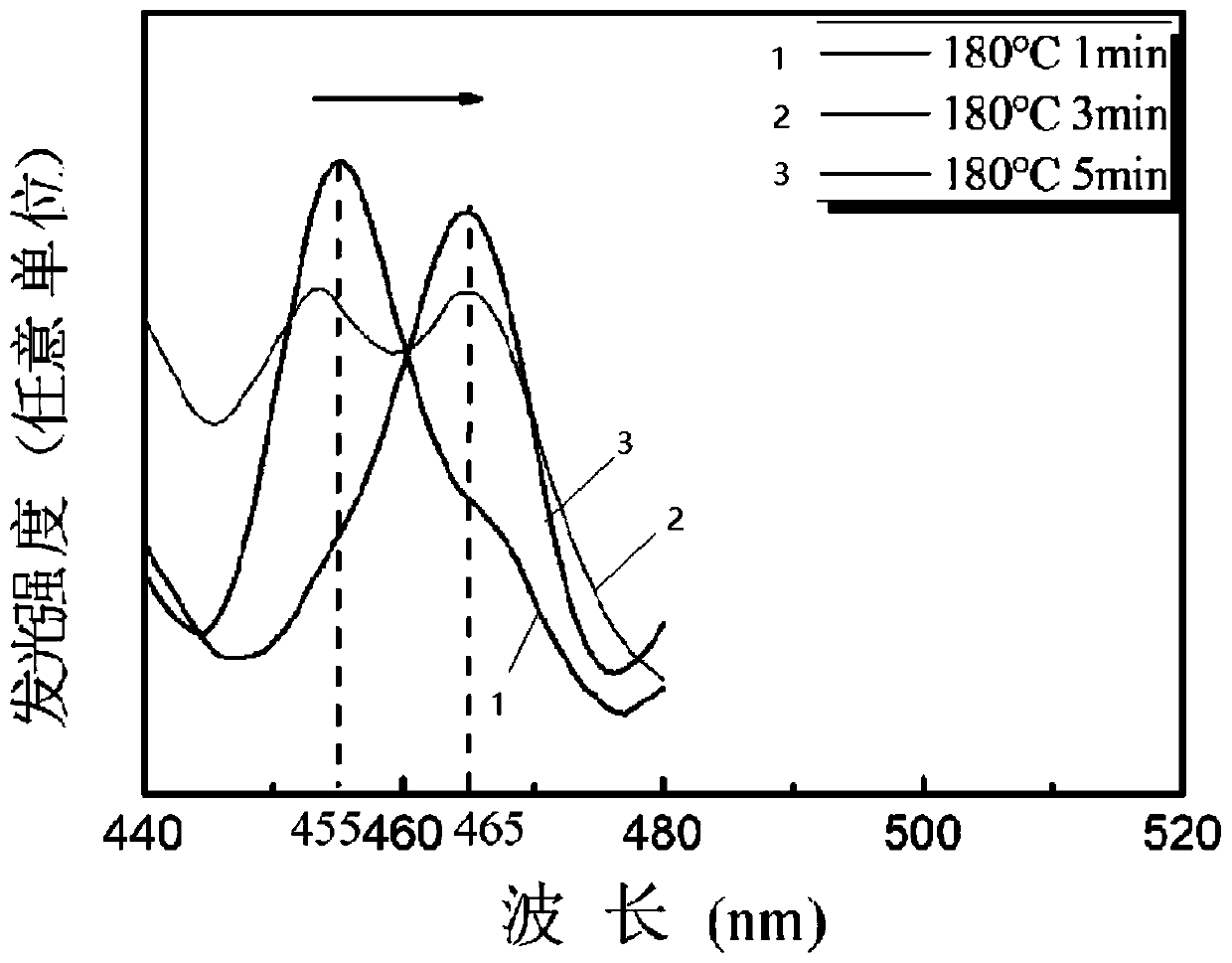

[0021] This example is the same as Example 1, except that the reaction temperature in Example 1 is changed from 140° C. to 180° C., and the reaction time is changed to 1, 3, and 5 minutes. See the test results figure 2 and image 3 , it can be seen that there is only 454nm main peak at 1min, and there are two main peaks in the emission spectrum at 3min, and the emission peak is red-shifted from 454nm to 464nm at 5min, indicating that the crystal structure of the nanosheets has changed from hexagonal wurtzite to face-centered cubic sphalerite .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com