Treatment method for improving electrochemical performance of B-site doped perovskite catalyst

A treatment method and a doping-type technology, which is applied in the field of treatment to improve the electrochemical performance of B-site doped perovskite catalysts, and can solve problems such as performance gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

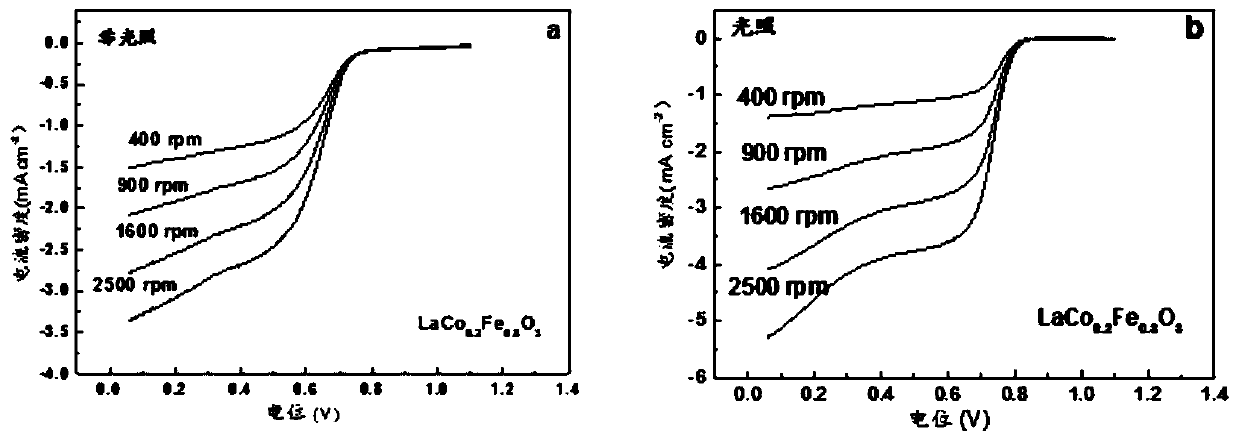

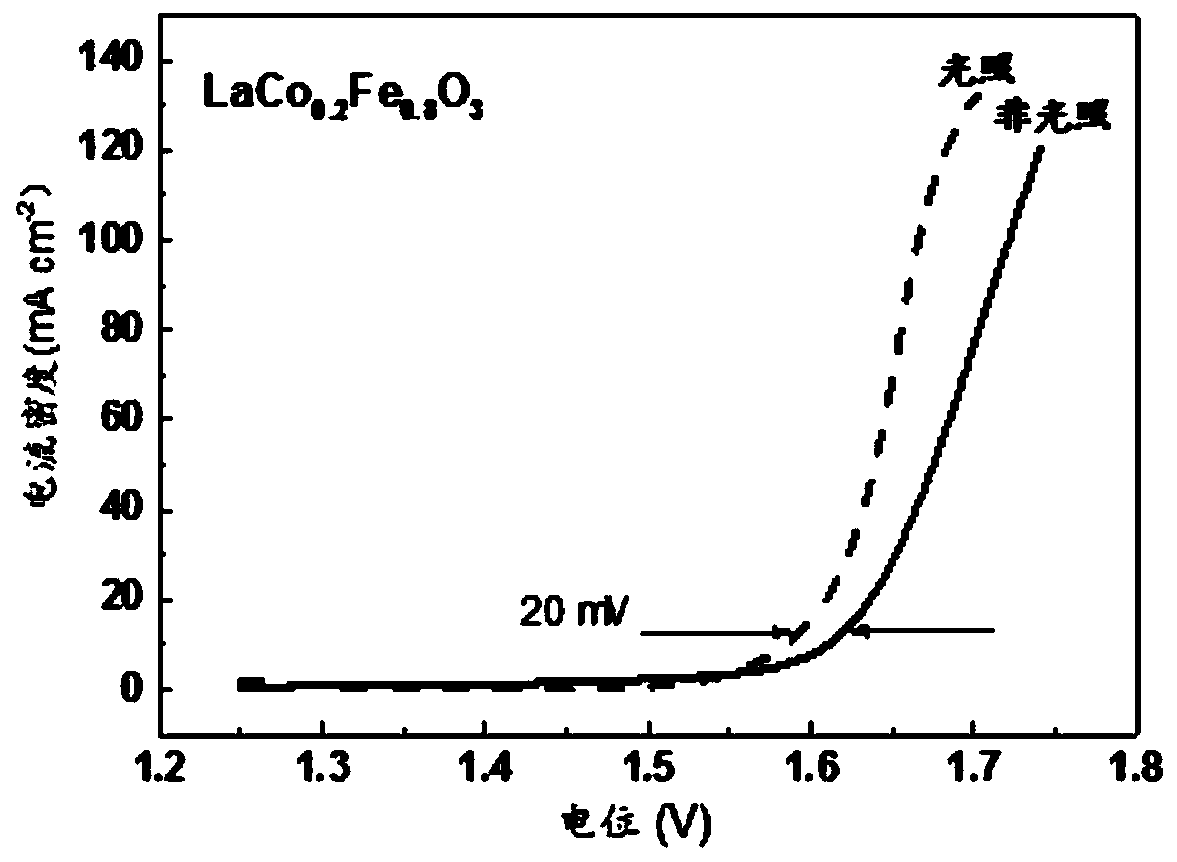

[0028] Example 1: Effect of light on the performance of B-site doped transition metal perovskite catalysts (1) Preparation of B-site Co-doped LaFeO 3 type catalyst (LaCo 0.2 Fe 0.8 o 3 ): (i) Dissolve lanthanum acetate, cobalt acetate, and iron acetate in deionized water according to the stoichiometric ratio, and after ultrasonic treatment for 30 minutes to form a homogeneous solution, add 0.1mol L -1Lithium hydroxide was used to adjust the pH of the solution to 9, and stirring was continued for 2 hours. (ii) Centrifugation and washing: Centrifuge at a speed of 10000rpm for 10 minutes to obtain a solid product, then use a mixed solution of ethanol and deionized water to centrifugally wash the solid product for 3 times, and dry it for 8 hours at a temperature of 60°C. A composite hydroxide precursor is obtained. (iii) High-temperature calcination: The composite hydroxide precursor prepared in (ii) was calcined at 600 °C for 2 h in an air atmosphere to obtain Co-doped LaFeO ...

Embodiment 2

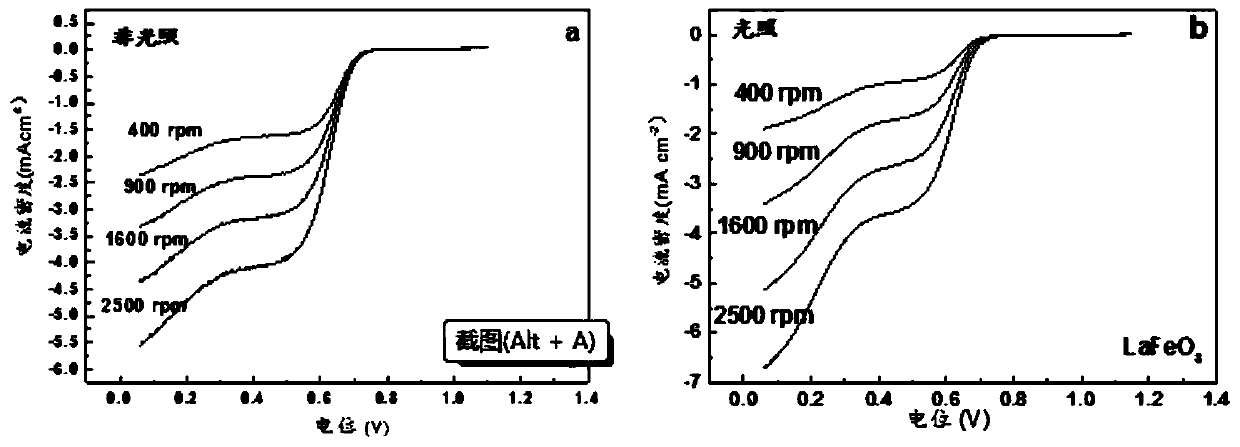

[0036] Example 2: Effect of light on the performance of undoped perovskite catalysts

Embodiment 3

[0046] Example 3: Effect of light on the performance of B-site doped perovskite catalysts with non-transition metals

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com