Lithium-ion ternary positive electrode material with high nickel and low free lithium and its preparation method and application

A positive electrode material, lithium ion technology, applied in the field of preparation of high-nickel ternary positive electrode materials, can solve the problems of poor safety of lithium ion batteries, uneven crystal growth, high content of free lithium, etc., to achieve structural stability and good safety performance , the effect of high particle content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

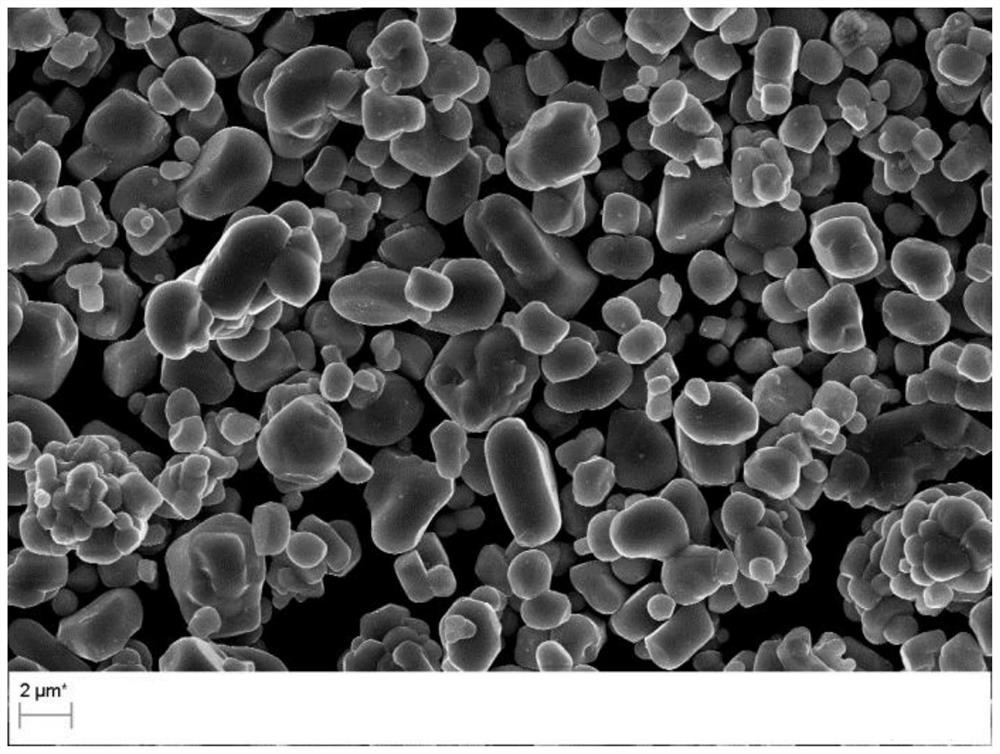

Embodiment 1

[0098] Take by weighing 27kg monohydrate cobalt carbonate (industrial grade, purity 99wt%), 29.0kg tetrahydrate cobalt acetate (industrial grade, purity 99.0wt%), 115.3kg hexahydrate nickel acetate (industrial grade, purity 99.5%), 17.0kg single Manganese sulfate water, 20.22kg manganese acetate (industrial grade, purity 99.5%) powder, 0.015kg nanometer magnesium oxide (ceramic grade, purity 99.5%), 0.045kg magnesium carbonate (ceramic grade, purity 99.7%) joins in the kneader. Then take the container and slowly add 200.0kg of industrial acetic acid (industrial grade, purity 99.5%, its addition amount is 200% of the mass of the active component of the positive electrode material obtained in theory), and 50kg of deionized water to prepare about 30% acetic acid aqueous solution , and then slowly add the above aqueous acetic acid solution into the kneader under stirring, while controlling the reaction temperature of the solution to be 55°C±5°C. The dropwise addition time is 4h. A...

Embodiment 2

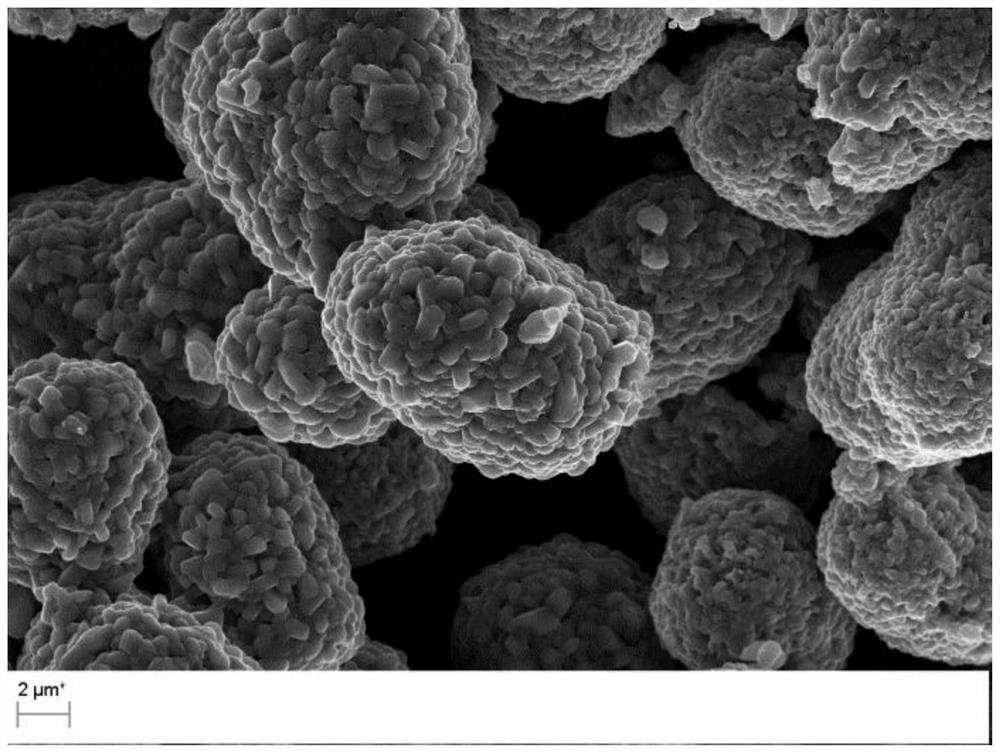

[0105] Take by weighing 19.45kg cobalt carbonate (technical grade, purity 99wt%), 199.6kg nickel sulfate hexahydrate (technical grade, purity 99.0wt%), 18.8kg manganese carbonate powder (technical grade, purity 99.0wt%) join in the kneader , 0.033kg zirconia (ceramic grade, purity 99.5wt%), slowly add 500.0kg industrial adipic acid (industrial grade, purity 99.5wt%), and its addition is 500% of the positive electrode material active component quality that makes theoretically ), while controlling the reaction temperature of the solution to be 55°C±5°C. Adding time is 4h, add and add 0.92kg zirconium nitrate pentahydrate (industrial grade, 95wt%) again, 0.33kg nano zirconium oxide (ceramic grade, purity 99.5wt%) powder is aged under stirring state for 30 hours, and then use The diaphragm pump is pumped into the high-speed centrifuge for centrifugation, and a pipeline demagnetizer is installed on the pumping pipeline to demagnetize (magnetic field strength 11000GS) until the impu...

Embodiment 3

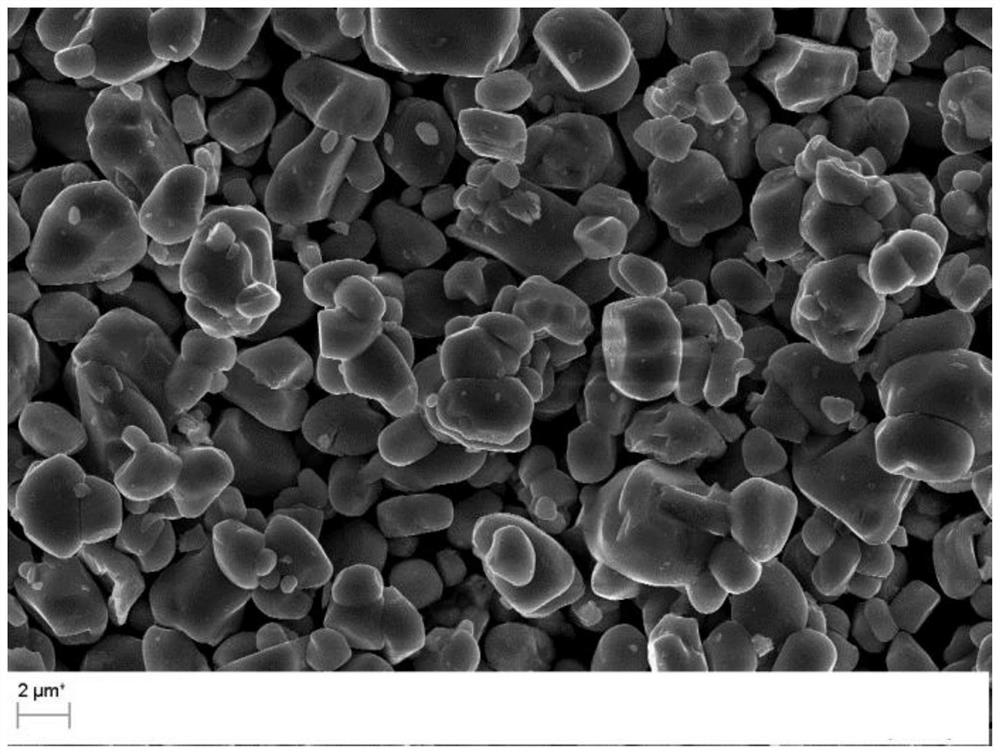

[0110] Take by weighing 30.88kg cobalt sulfate heptahydrate (technical grade, purity 98wt%), 104.6kg nickel carbonate (technical grade, purity 99.0wt%), 16.7kg manganese sulfate monohydrate (technical grade, purity 99.5wt%) powder joins in kneading in the plane. Take the container again and slowly add 80.0kg industrial isooctanoic acid (industrial grade, purity 99.5%, its addition is 80% of the mass of the positive electrode material active ingredient that is theoretically prepared), and 70kg deionized water, to be mixed with about 83% acetic acid aqueous solution, and then slowly add the above aqueous acetic acid solution into the kneader under stirring, while controlling the reaction temperature of the solution to be 55°C±5°C. Adding time is 4h, add 0.09kg nanometer magnesia (ceramic grade, purity 99.5wt%) powder again after dropping, 1.05kg nanometer zirconia (ceramic grade, purity 99.5wt%), aging 30 under stirring state Hours, then use a diaphragm pump to pump into a high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com