Electrochemical Synchronous Testing System for Elbow Corrosion and Wear under Different Impact States

A synchronous test, corrosion and wear technology, applied in the direction of testing wear resistance, weather resistance/light resistance/corrosion resistance, measuring device, etc. Ensuring accuracy and rigor, reducing test costs, and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

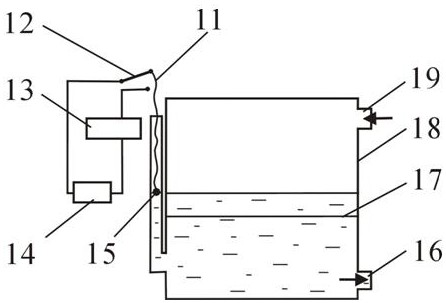

Image

Examples

Embodiment

[0121] 1) System information:

[0122] The reservoir material is an acrylic plate, which has a capacitive volume of 12m 3 ;

[0123] Sand liquid separation box material is an acrylic plate, which is effective volume of 8M 3 ;

[0124] Both the main pipe and the auxiliary conduit are acrylic tubes, and the elbow pipes are also bent by the acrylic tube. The inner diameter of the pipe is 90mm, and the wall thickness is 5 mm.

[0125] The study sample diameter was 8 mm.

[0126] 2) Test parameters:

[0127] Corrosion: 1 mol / l NaCl solution

[0128] Solid phase particles: quartz sand having less than 200 mesh particles;

[0129] W 液 : W 砂 = 4: 1;

[0130] Multiphase flow flow rate: 1.2m / s;

[0131] Test material: P110 steel.

[0132] 3) Test results:

[0133] Result 1: Instant corrosion rate

[0134] like Figure 7 It is the polarization curve measured by the electrochemical workstation when the P110 steel is corroded around 30 ° elbow, 120 min, and 240 min.

[0135] By trying to fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com