Preparing method of flexible carbon nanotube/metal composite film applied to electromagnetic shielding field

A carbon nanotube film and carbon nanotube technology, applied in the direction of carbon nanotubes, nanocarbons, carbon compounds, etc., can solve problems such as uneven current distribution, increased production costs, and large resistance, and achieve reduced overall weight and combined Strong, evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

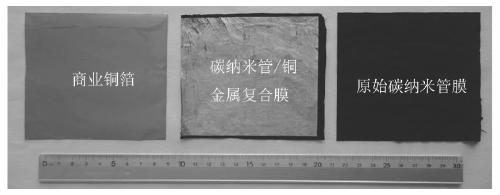

Image

Examples

Embodiment 1

[0015] Step 1, surface morphology construction of carbon nanotube film: prepare macroscopic continuum of carbon nanotubes by floating cracking chemical vapor deposition method, collect through collection device and transfer to rolling equipment for rolling to form film; select surface microscopic The metal thin plate or metal foil with regular shape is used as the substrate material, and the substrate material is covered on the macroscopic continuum of carbon nanotubes, and it is rolled synchronously with it at a pressure of 100 MPa; the macroscopic continuum of carbon nanotubes after rolling is Compressed into a carbon nanotube film with a thickness of 1 μm, and has a surface microscopic morphology similar to metal foil; separate the carbon nanotube film from the substrate material for use;

[0016]Step 2, configuration of electrodeposition solution: weigh the sulfate and chloride salt of the metal to be deposited according to the mass concentration of 10 g / L and 10 g / L respec...

Embodiment 2

[0021] Step 1, surface morphology construction of carbon nanotube film: prepare macroscopic continuum of carbon nanotubes by floating cracking chemical vapor deposition method, collect through collection device and transfer to rolling equipment for rolling to form film; select surface microscopic The metal thin plate or metal foil with regular shape is used as the substrate material, and the substrate material is covered on the macroscopic continuum of carbon nanotubes, and it is rolled synchronously with it at a pressure of 50 MPa; the macroscopic continuum of carbon nanotubes after rolling is Compressed into a carbon nanotube film with a thickness of 2 μm, and has a surface microscopic morphology similar to metal foil; separate the carbon nanotube film from the substrate material for use;

[0022] Step 2, configuration of electrodeposition solution: weigh the sulfate and chloride salt of the metal to be deposited according to the mass concentration of 20 g / L and 50 g / L respec...

Embodiment 3

[0027] Step 1, surface morphology construction of carbon nanotube film: prepare macroscopic continuum of carbon nanotubes by floating cracking chemical vapor deposition method, collect through collection device and transfer to rolling equipment for rolling to form film; select surface microscopic The metal thin plate or metal foil with regular shape is used as the substrate material, and the substrate material is covered on the macroscopic continuum of carbon nanotubes, and it is rolled synchronously with it at a pressure of 500 MPa; the macroscopic continuum of carbon nanotubes after rolling is Compressed into a carbon nanotube film with a thickness of 2 μm, and has a surface microscopic morphology similar to metal foil; separate the carbon nanotube film from the substrate material for use;

[0028] Step 2, configuration of electrodeposition solution: weigh the sulfate and chloride salt of the metal to be deposited according to the mass concentration of 250 g / L and 70 g / L resp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com