A kind of magnesium-based alloy modulated thin film and its preparation method and application

A technology of magnesium-based alloys and magnesium alloys, applied in metal material coating technology, vacuum evaporation plating, coating, etc., to achieve fast hydrogenation speed, large application value, and improved sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

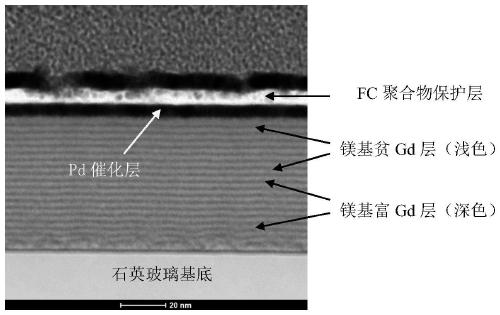

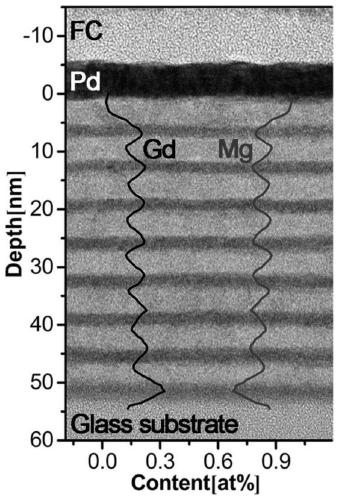

[0054] The invention provides a magnesium-based alloy modulation film for a hydrogen sensor and a preparation method thereof, comprising the following steps:

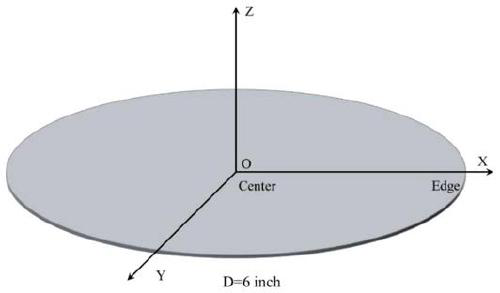

[0055] (1) Prepare a mixture of concentrated sulfuric acid and hydrogen peroxide (3:1) as a cleaning solution, soak the substrate in the above solution for 10 minutes, then rinse it with deionized water, then ultrasonically clean it for 10 minutes, and finally blow it with nitrogen And placed in an oven to dry (50 ° C, 0.5h). Put the cleaned quartz glass substrate into the magnetron sputtering reaction chamber, and the placement position of the film is located on the sample stage ( figure 1 ) at the edge (r=7.6cm), turn on the vacuum system for vacuuming until the background vacuum of the deposition chamber is 6.67×10 -4 Pa;

[0056] (2) Introduce the working gas, turn on the power of the magnesium and gadolinium targets, and pre-sputter for 10 minutes to clean the targets. Set the sputtering power of the magnesium ...

Embodiment 2

[0063] The invention provides a magnesium-based alloy modulation film for a hydrogen sensor and a preparation method thereof, comprising the following steps:

[0064] (1) Prepare a mixture of concentrated sulfuric acid and hydrogen peroxide (3:1) as a cleaning solution, soak the substrate in the above solution for 10 minutes, then rinse it with deionized water, then ultrasonically clean it for 10 minutes, and finally blow it with nitrogen And placed in an oven to dry (50 ° C, 0.5h). Put the cleaned quartz glass substrate into the magnetron sputtering reaction chamber. The thin film is placed at 1 / 2 of the center and edge of the sample stage (r=3.8cm). Turn on the vacuum system to vacuum until the background Vacuum degree is 6.67×10 -4 Pa;

[0065] (2) Introduce the working gas, turn on the power of the magnesium and gadolinium targets, and pre-sputter for 10 minutes to clean the targets. Set the sputtering power of the magnesium and gadolinium targets to 100W and 50W respec...

Embodiment 3

[0070] The invention provides a magnesium-based alloy modulation film for a hydrogen sensor and a preparation method thereof, comprising the following steps:

[0071] (1) Prepare a mixture of concentrated sulfuric acid and hydrogen peroxide (3:1) as a cleaning solution, soak the substrate in the above solution for 10 minutes, then rinse it with deionized water, then ultrasonically clean it for 10 minutes, and finally blow it with nitrogen And placed in an oven to dry (50 ° C, 0.5h). Put the cleaned quartz glass substrate into the magnetron sputtering reaction chamber, place the film at the position of r=2.5cm on the sample stage, turn on the vacuum system to vacuumize until the background vacuum is 6.67×10 -4 Pa;

[0072] (2) Introduce the working gas, turn on the power of the magnesium and gadolinium targets, and pre-sputter for 10 minutes to clean the targets. Set the sputtering power of the magnesium and gadolinium targets to 200W and 100W respectively, the sputtering tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com