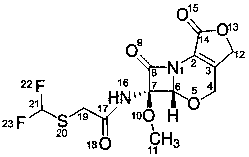

Preparation and structure confirmation method of lactone impurities in flomoxef sodium

A technology of fluoxefom sodium and impurities, which is applied in the field of preparation and structure confirmation of lactone impurities in fluoxefom sodium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

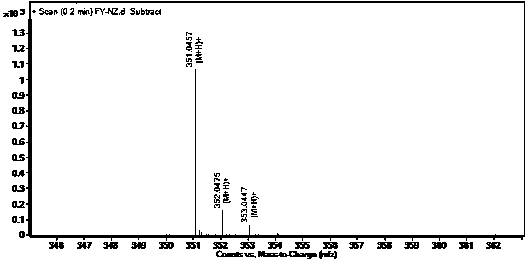

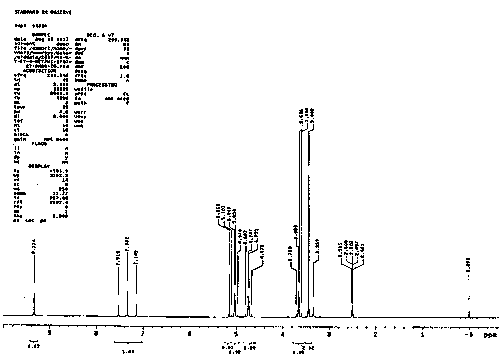

Image

Examples

Embodiment 1

[0028] 1. Preparation of impurities

[0029] The chromatographic conditions are as follows: Agilent 1200 high-performance liquid chromatography, octadecylsilane bonded silica gel as a semi-preparative column (10mm × 250mm, 10 μm) as a filler, 5mmol / L ammonium acetate solution-methanol (the volume ratio of the two 700-900:300-100) as the mobile phase, take an appropriate amount of sample, dissolve it in water, and prepare the test solution for 10-200mg / ml impurities, the injection volume is 100μl, the flow rate is 1-3ml / min, and the detection wavelength is 246nm. The column temperature is 30°C. Under the chromatographic conditions, the fluoxetal sodium peaks out in about 10 minutes, and the impurities peak out in about 17 minutes. After the impurities are detected by the ultraviolet detector, the fractions are collected after the column is started at the peak position, and the samples are enriched.

[0030] Take the collected fractions and concentrate them under reduced pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com