Automatic positioning equipment applied to quartz product

An automatic positioning and product technology, which is applied in glass manufacturing equipment, glass production, glass forming, etc., can solve the problems of unsatisfactory positioning accuracy, rising labor cost of skilled workers, long production cycle, etc., and facilitate welding and other processing procedures , save manpower and material resources and time, and move with subtle and precise effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the examples, but not as a basis for limiting the present invention.

[0024] Example.

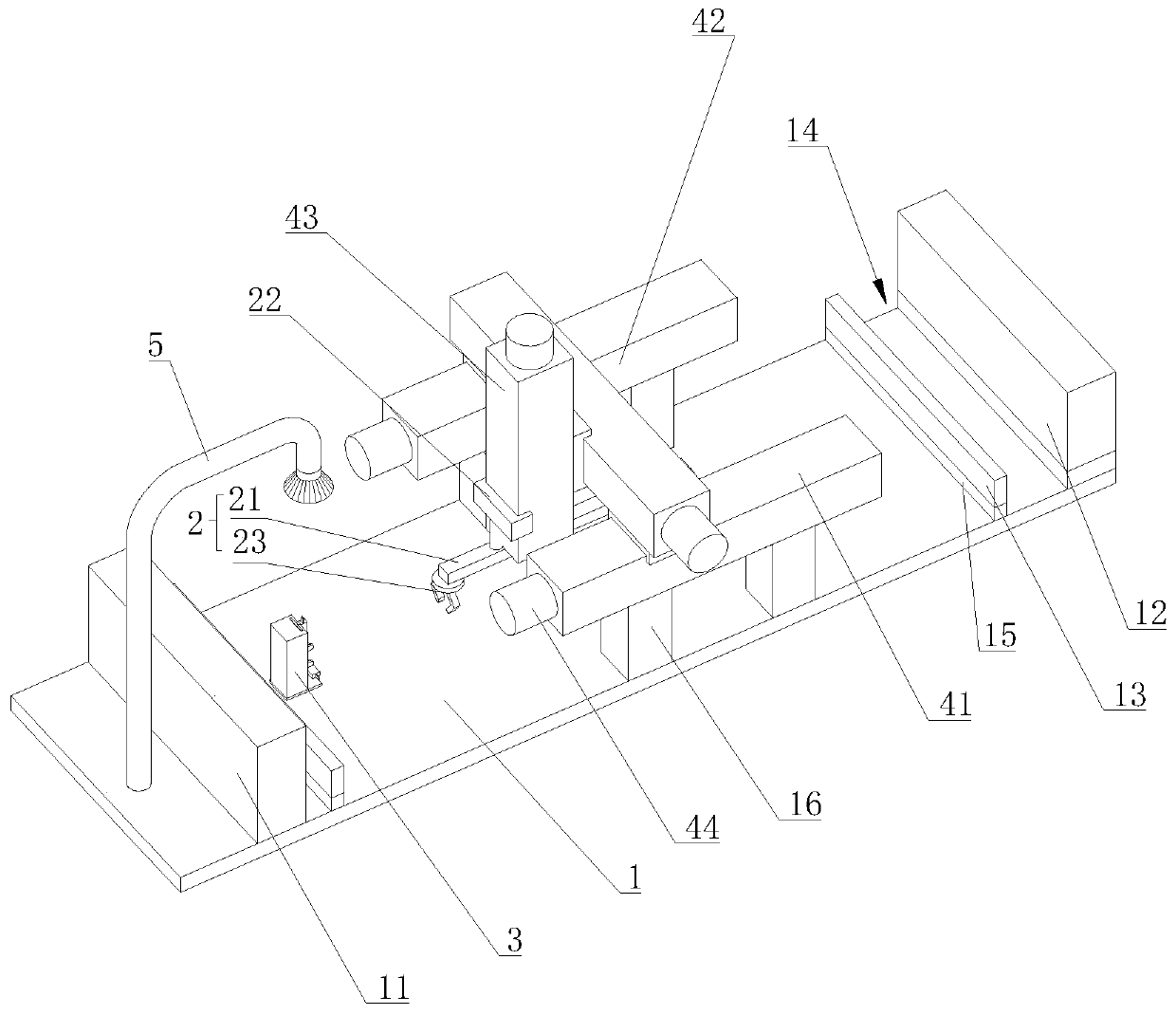

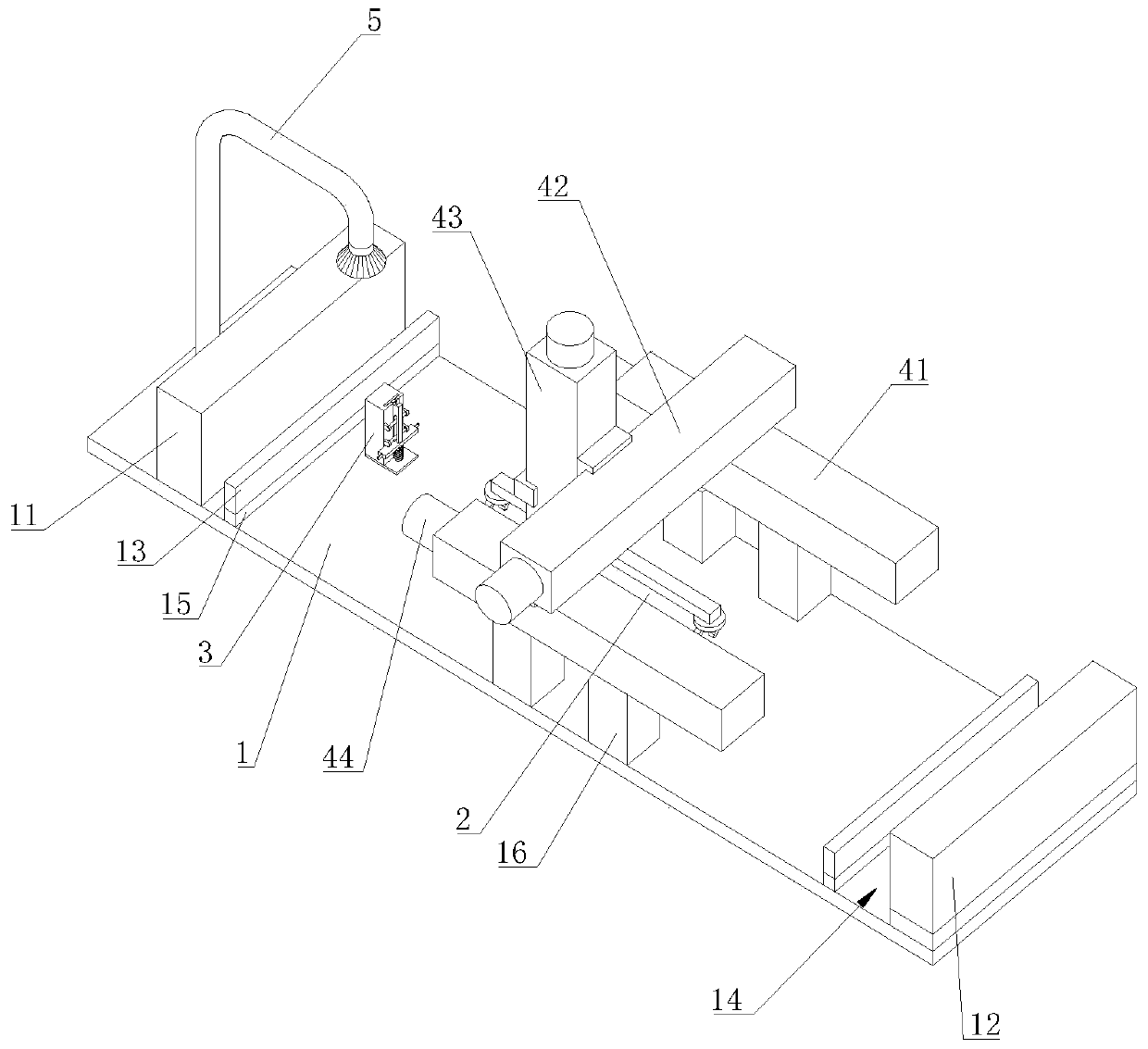

[0025] Such as Figure 1-3 As shown, an automatic positioning device applied to quartz products, including a workbench 1, the two ends of the workbench 1 are provided with end fixing components, and the workbench 1 is provided with a three-axis automatic movement device and The positioning component 3 is equipped with a part gripper 2 on the three-axis automatic moving device, and the three-axis automatic moving device drives the part gripper 2 to move up, down, front, back, left, and right, and the positioning component 3 and the end fixing component realize the positioning of the quartz product.

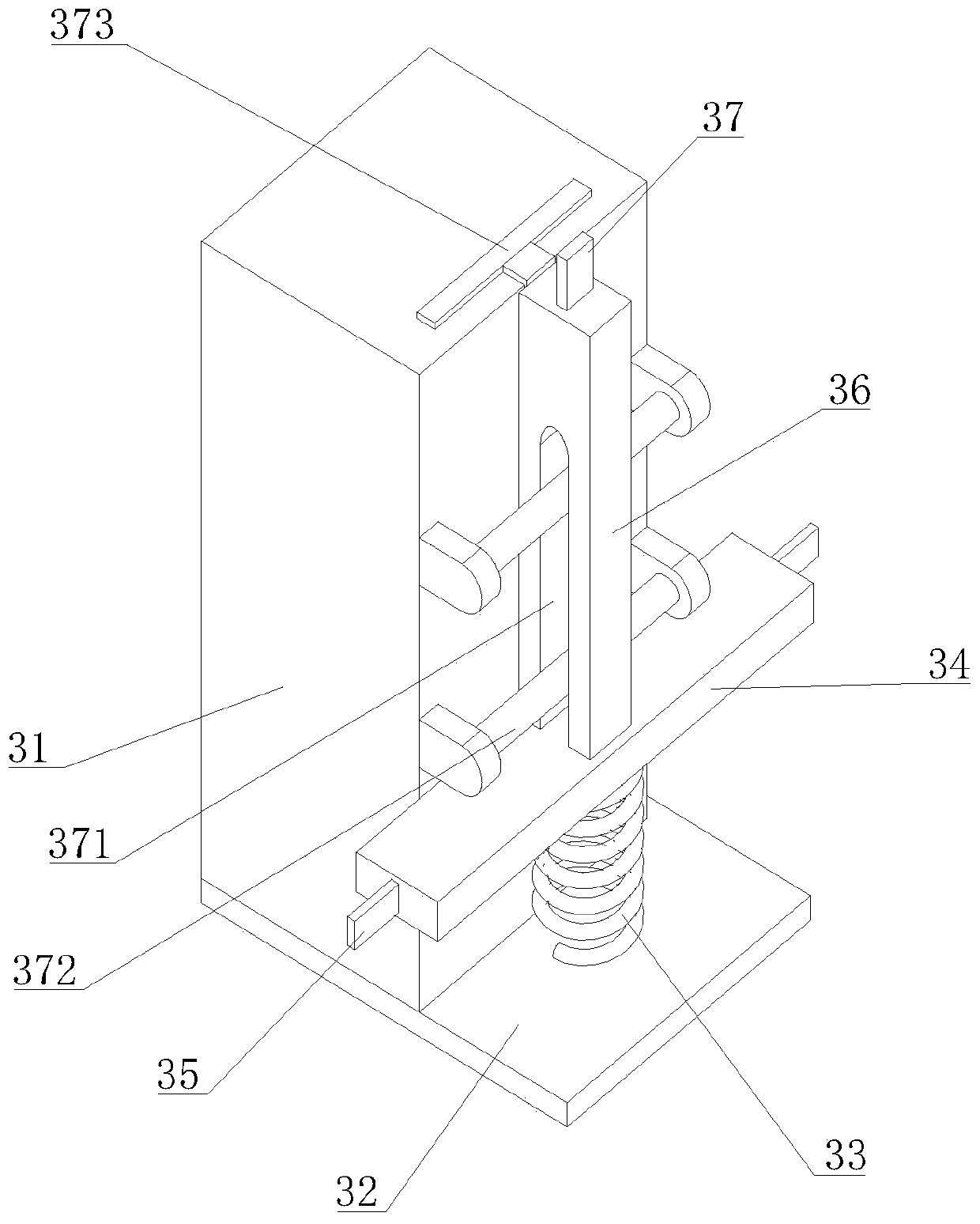

[0026] The positioning assembly 3 includes a mounting base 31, the mounting base 31 is connected to the workbench 1 through a fixed base plate 32, and the fixed base plate 32 is provided with an elastic member 33 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com