Preparation method of positive plate used for indigo waste water processing

A technology for wastewater treatment and anode plate, applied in the field of electrochemical treatment, can solve the problem of inappropriate treatment process, poor comprehensive properties such as tensile strength and resistivity of quaternary alloy electrode materials, and unsatisfactory degradation and removal effect of organic components, etc. To achieve the effect of enhancing the color adsorption capacity, improving the decolorization capacity, and enhancing the processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be further defined below in conjunction with the implementation of the specific test operation process, but the scope of protection is not limited to the description made.

[0028] In some embodiments, the method for preparing an anode plate for indigo wastewater treatment comprises the following steps:

[0029] (1) Lead is added in the graphite crucible, heated and melted to form a molten liquid;

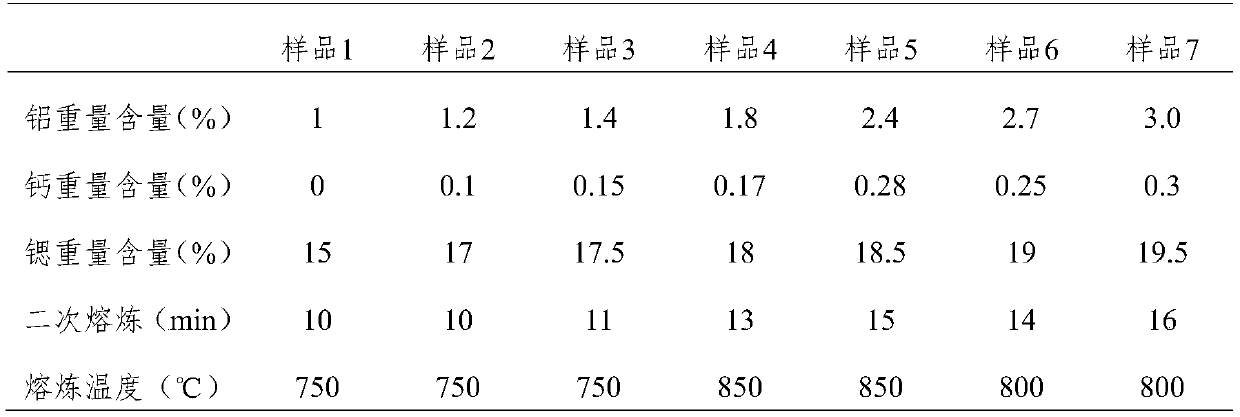

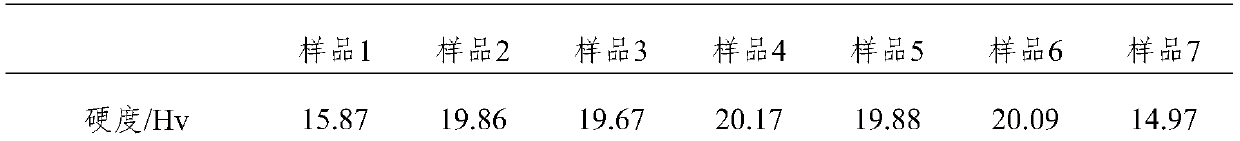

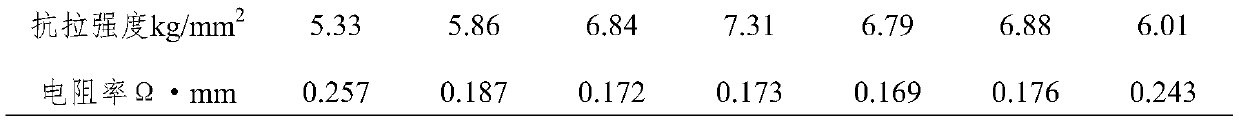

[0030] (2) Control the molten liquid to be at 750-850°C, add aluminum to it at a weight content of 1.2-2.7%, and smelt once at a constant temperature. After the aluminum is completely melted into a liquid state, a metal liquid is obtained;

[0031] (3) Control the temperature at 750-850°C, add calcium to it at a weight content of 0.1-0.28% and strontium at a weight content of 17-19%, stir at a constant temperature for secondary smelting, cast into ingots, calcined and rolled, punched, The anode plate for indigo wastewater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com