Method for preparing titanium and titanium alloy powder for 3D printing on basis of fluidized bed jet milling technology

A 3D printing and fluidized bed technology, applied in powder suspension granulation, additive manufacturing, metal processing equipment, etc., can solve the problem of low cost and stable production of spherical titanium powder, low yield of fine particle size titanium powder, Facing the high cost of milling equipment and other issues, it achieves the effects of cost reduction, high production efficiency and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

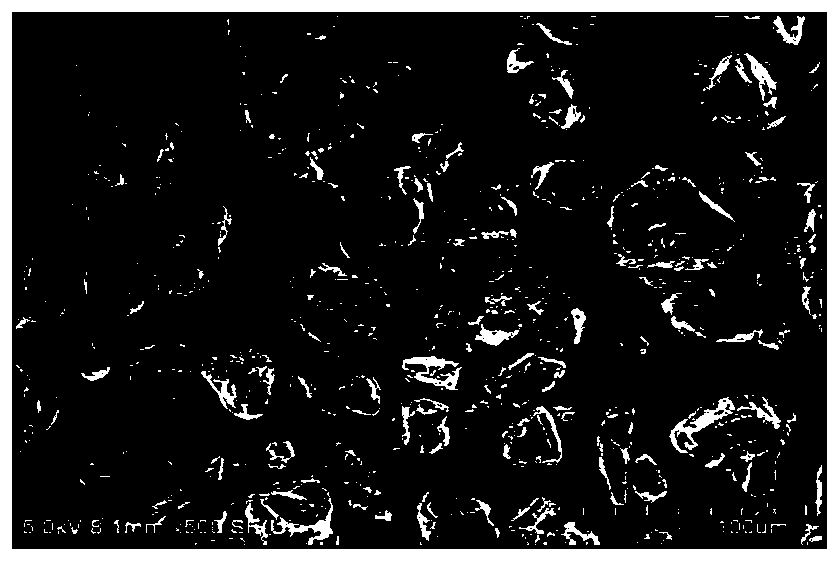

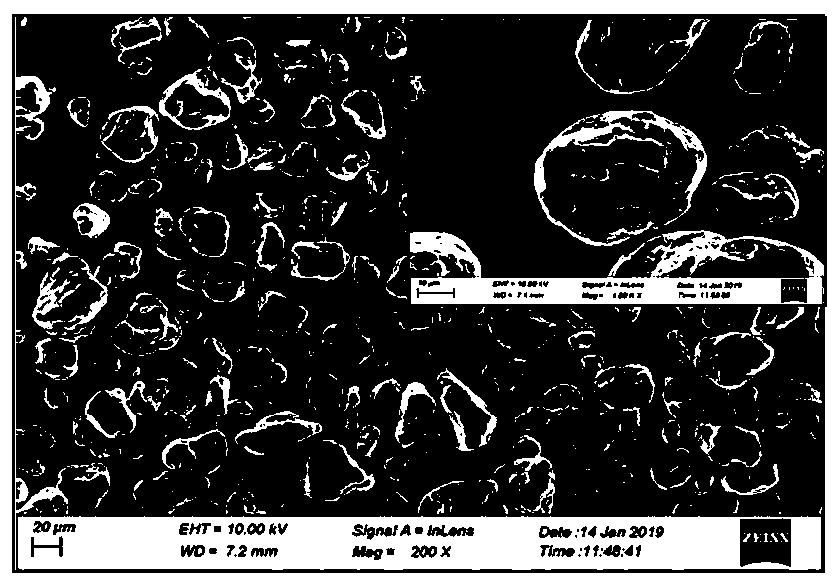

[0019] When using the titanium powder of the present invention, the hydrogenated dehydrogenation titanium powder of the irregular shape used has an oxygen content of 1200PPM, a quality of 400g, a particle size below 325 mesh, and an included angle between the fluidized bed jet mill nozzle and the grinding chamber wall surface of 60°. Use high-purity nitrogen as the grinding gas, the pressure of the grinding gas is 0.6MPa, the frequency of the sorting wheel is 60Hz / min when feeding, 0 when discharging, and the grinding time is 6min, such as figure 1 As shown, the morphology of the titanium powder before treatment is irregular, and the titanium powder after jet milling is nearly spherical, such as figure 2 As shown, the sphericity is improved, the surface smoothness is higher, the fluidity is 35s / 50g, and the oxygen content is 1400PPM.

[0020] The whole process of the present invention is time-consuming and requires low equipment. Only by adjusting the gas flow rate and grindi...

Embodiment 2

[0022] In this embodiment, the irregular hydrogenated dehydrogenation titanium powder described in the above-mentioned embodiment 1 is used, the oxygen content is 1200PPM, the mass is 600g, and the particle size is 325 mesh. The angle between the nozzle of the fluidized bed jet mill and the wall of the grinding chamber is 60°. Nitrogen is used as the grinding gas. The pressure of the grinding gas is 0.6MPa. The time is 4 minutes, the obtained titanium powder is nearly spherical, the surface is relatively smooth, the fluidity is 41s / 50g, and the oxygen content is 1600PPM.

Embodiment 3

[0024] This embodiment adopts the hydrogenated dehydrogenation titanium powder described in the above embodiment 1, the oxygen content is 1200PPM, the mass is 600g, and the particle size is 200 mesh. The angle between the nozzle of the fluidized bed jet mill and the wall of the grinding chamber is 60°, nitrogen is used as the grinding gas, the pressure of the grinding gas is 0.45 MPa, the frequency of the sorting wheel is 50 Hz / min, and the grinding time is 6 min. The obtained titanium powder is nearly spherical, The fluidity is 33s / 50g, and the oxygen content is 1600PPM.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com