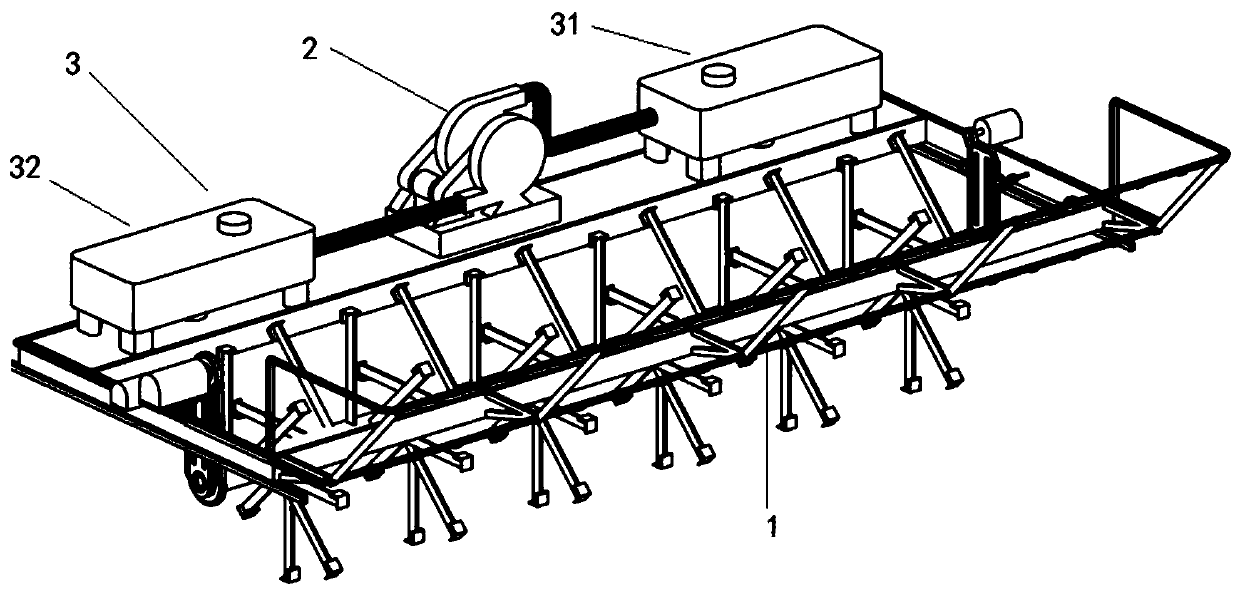

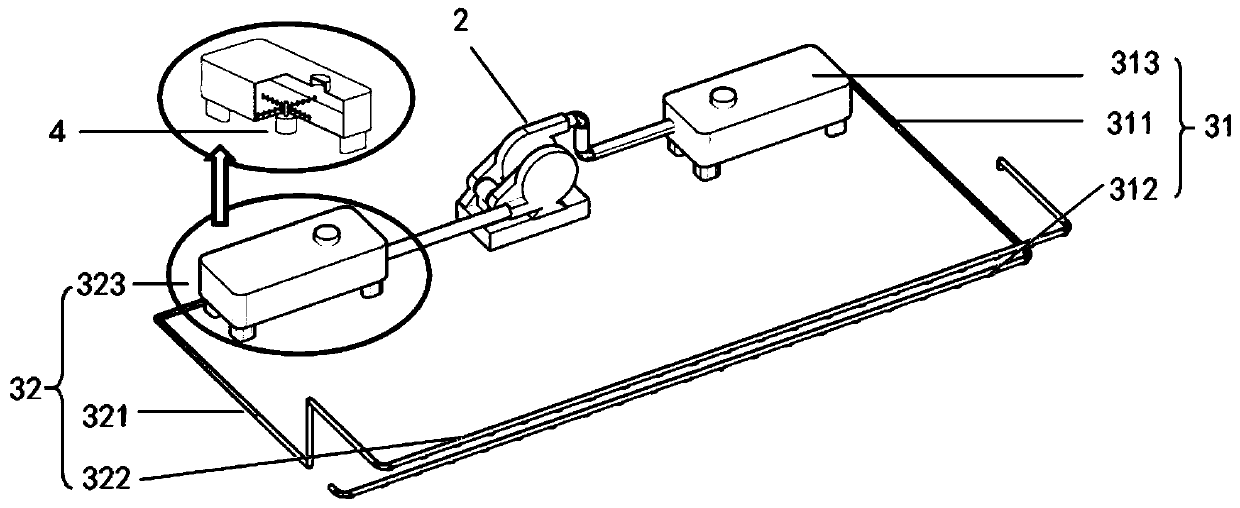

Equipment for emission reduction of poultry and livestock excrement fermentation odor and deodorization method

A technology for livestock and poultry manure and odor, which is applied in the field of harmless treatment of livestock and poultry waste, and can solve problems such as harm to humans and animals, unsuitable fermentation conditions, and inability to deodorize operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

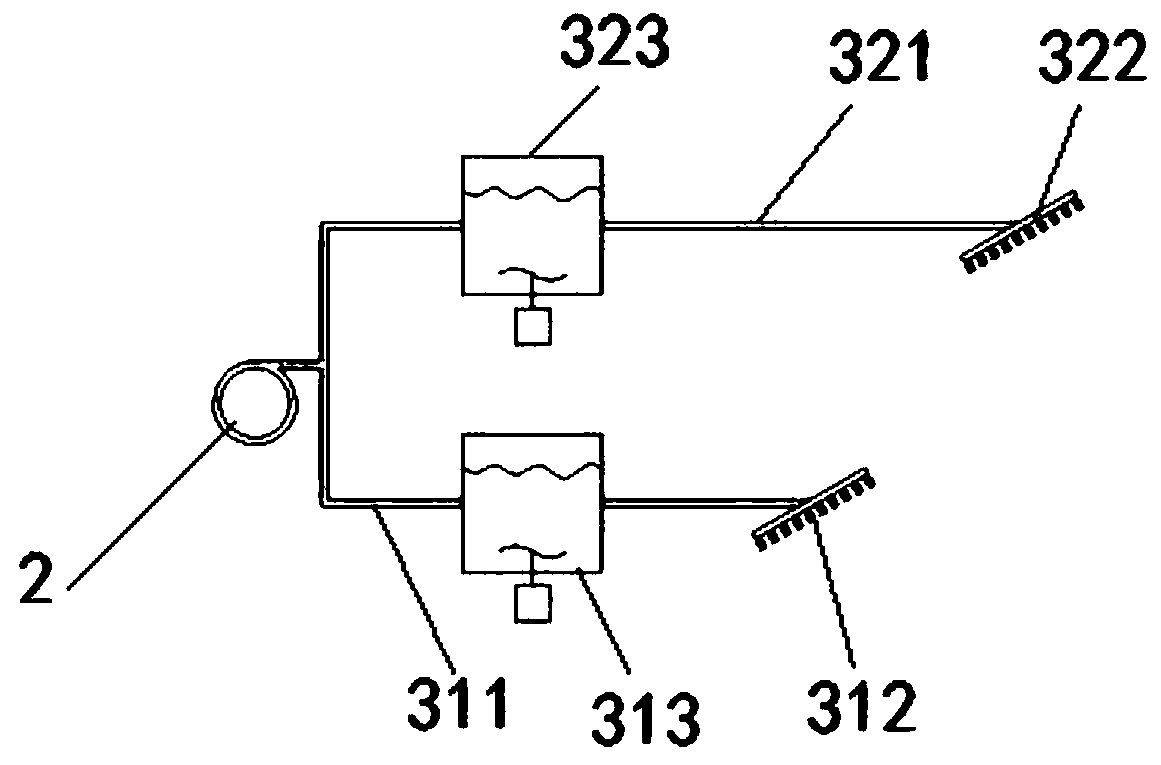

[0058] In this embodiment, the formula in the first deodorizing liquid is replaced by: solid citric acid, 80% liquid lactic acid and water in parts by weight of 1 part, 1 part, and 398 parts; the rest are the same as in Example 1.

Embodiment 3

[0060] In this embodiment, the formula in the first deodorizing liquid is replaced by: solid citric acid, 80% liquid lactic acid and water in parts by weight of 30 parts, 30 parts, and 340 parts; the rest are the same as in Example 1.

Embodiment 4

[0062] In this embodiment, the formula in the first deodorizing liquid is replaced by: solid citric acid, 75% liquid lactic acid and water in parts by weight of 3 parts, 1 part, and 396 parts; the rest are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com