Low-noise high-efficiency food processing machine

A food processing machine, high-efficiency technology, applied in the field of food processing, can solve the problems of reduced crushing performance and crushing efficiency, changing the crushing performance of the crushing blade, and not solving the noise well, so as to reduce the crushing performance, improve the crushing performance, reduce noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

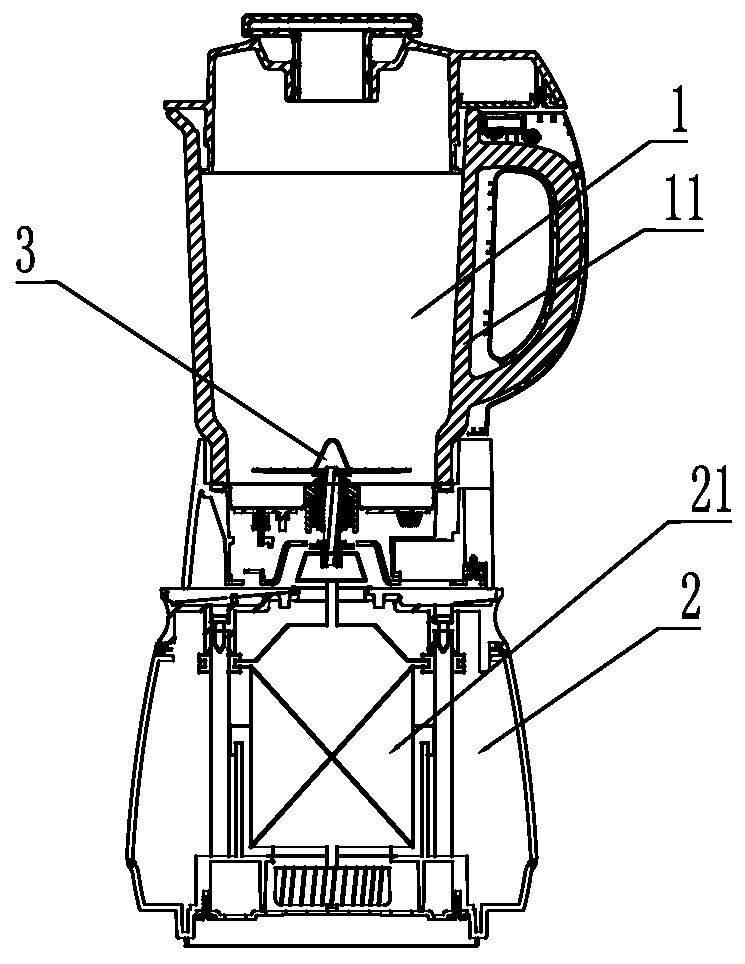

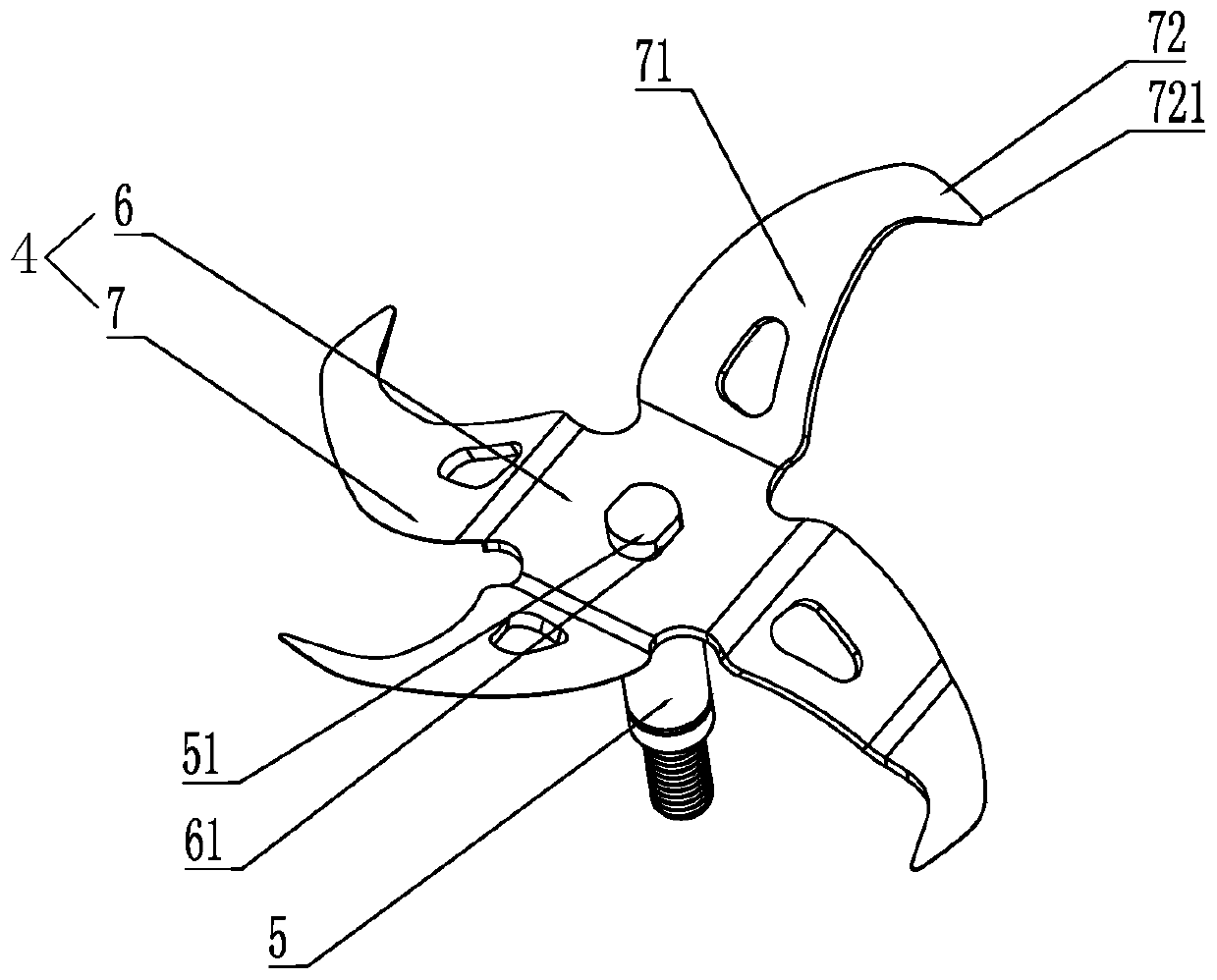

[0048] As the first embodiment of the low-noise and high-efficiency food processor of the present invention, further, as Figure 2-4 As shown, the crushing knife 3 includes a crushing blade 4 and a knife shaft 5, the crushing blade 4 is located in the cup body 11, and can cut and process the food in the cup body 11, and the knife shaft 5 passes through the cup body 11 , and is connected in transmission with the motor 21, the motor 21 drives the cutter shaft 5 to rotate and further drives the crushing blade 4 to rotate.

[0049] Such as figure 2 , 3 As shown, the crushing blade 4 includes a wing root 6 and a blade 7 . The wing root 6 is provided with a connecting hole 61 , and the upper end of the cutter shaft 5 is provided with a cutter shaft fixing platform 51 , and the cutter shaft fixing platform 51 passes through the connecting hole 61 and fixes the crushing blade 4 . Usually, after the crushing blade 4 passes through the cutter shaft fixing platform 51 , the crushing ...

Embodiment 2

[0075] Such as Figure 9 , 10 As shown, as the second embodiment of the food processor of the present invention, the difference from the first embodiment is that the pulverizing blade 4 includes a first pulverizing blade 41 and a second pulverizing blade 42 .

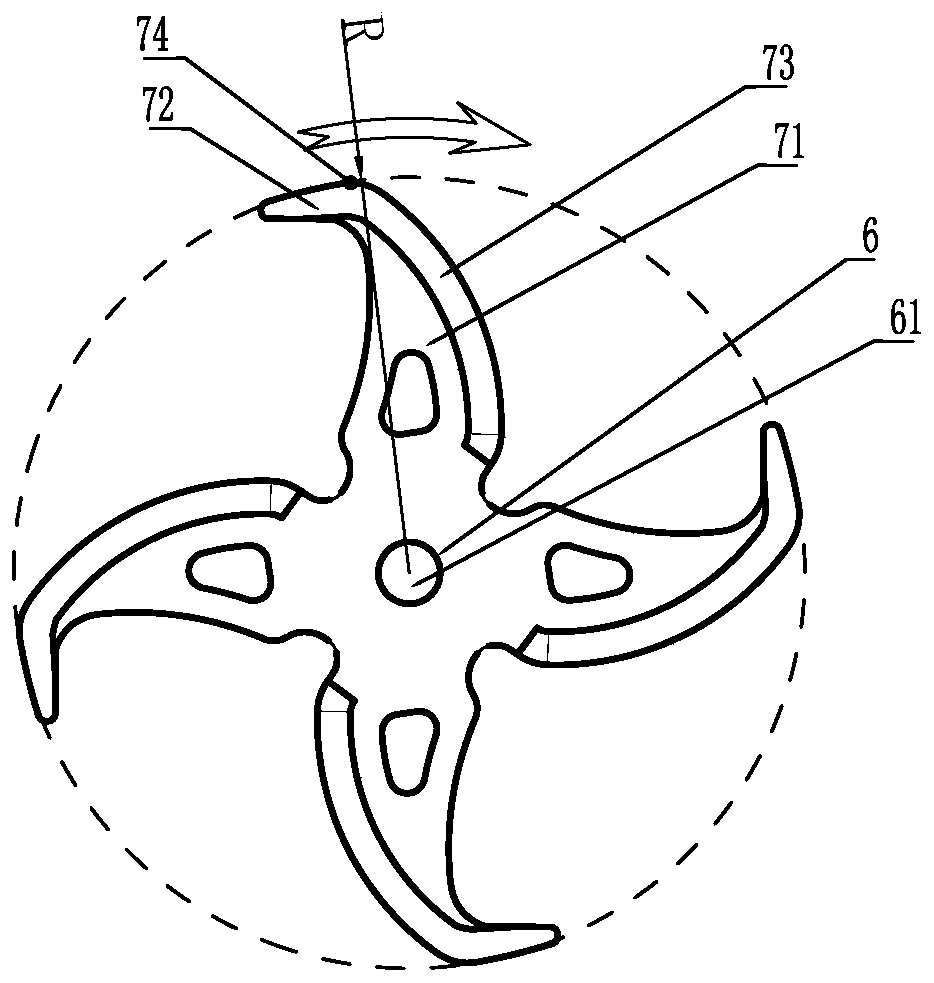

[0076] The first crushing blade 41 and the second crushing blade 42 are provided with wing roots and blades respectively, and the blades of the first crushing blade 41 and the second crushing blade 42 are provided with different bending dimensions. In this embodiment , the blade has 6 pieces.

[0077] Such as Figure 10 As shown, the part of the cutting edge 73 located at the crushing wing 71 includes a straight section, the length of the cutting edge from the cutting edge to the maximum point is L, and the radius of the maximum point is R, 1 / 3≤L / R≤1, preferably, said L / R=2 / 3. The advantage of such setting is: for the crushing wing provided with the straight section, the angle between the crushing wing and the exten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com