Conveyor belt monitoring device based on image and photoelectric information fusion

A monitoring device and conveyor belt technology, applied in the direction of conveyor control device, conveyor, conveyor objects, etc., can solve the problems of too short distance, reduced production efficiency, lack of monitoring, etc., and achieve increased relative distance and stable conveying direction. Change and ensure the effect of stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

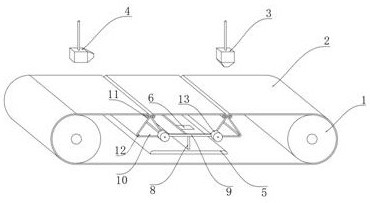

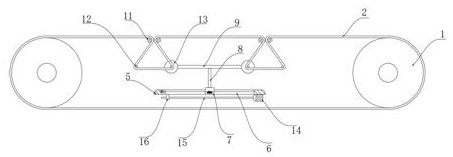

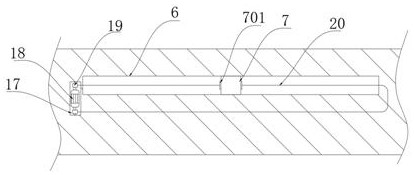

[0027] refer to Figure 1-5 , a conveyor belt monitoring device based on image and photoelectric information fusion, including a conveyor belt body, a photoelectric transmitter 3, and a photoelectric receiver 4, the conveyor belt body includes a belt body 2 and at least two rotating shafts 1, and the belt body 2 is sleeved on the rotating shaft 1, the rotating shaft 1 rotates under the action of an external power source, the photoelectric transmitter 3 and the photoelectric receiver 4 are provided with an image sensor, and the workpiece is transported on the conveyor belt body during use. The position information of the photoelectric receiver is sent to the processing unit of the photoelectric receiver; On the one hand, the processing unit of the photoelectric receiver 4 calculates the time interval between two measured objects according to the photoelectric information; Whether the distance between workpieces is within the normal range. If it exceeds the set value, it will ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com