Reliability test device of high-power laser chip

A technology of testing equipment and lasers, which is applied in the direction of electronic circuit testing, parts and instruments of electrical measuring instruments, etc., can solve problems such as difficult temperature control, high heat generation, and low testing efficiency, so as to ensure consistency and reduce differences , the effect of improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

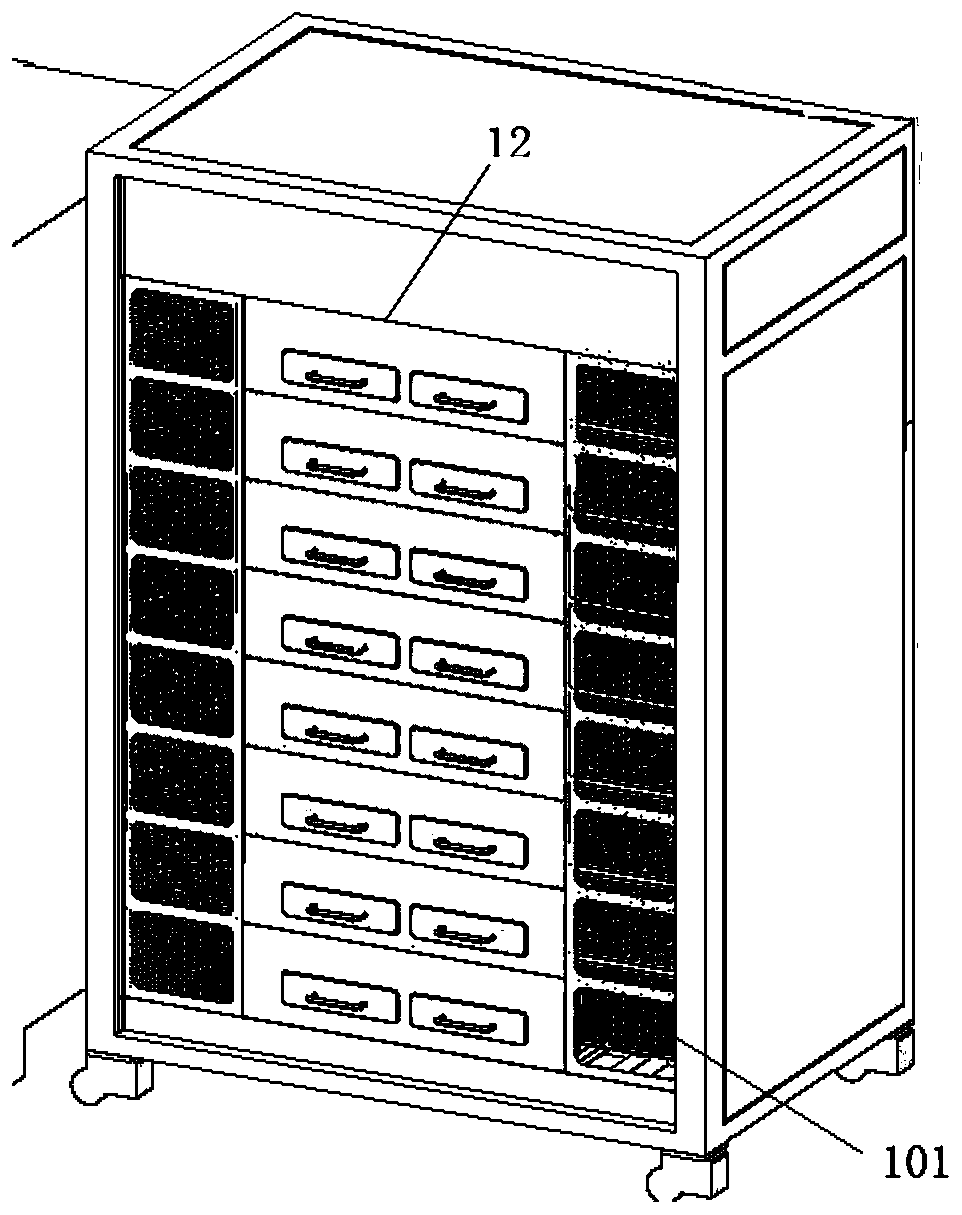

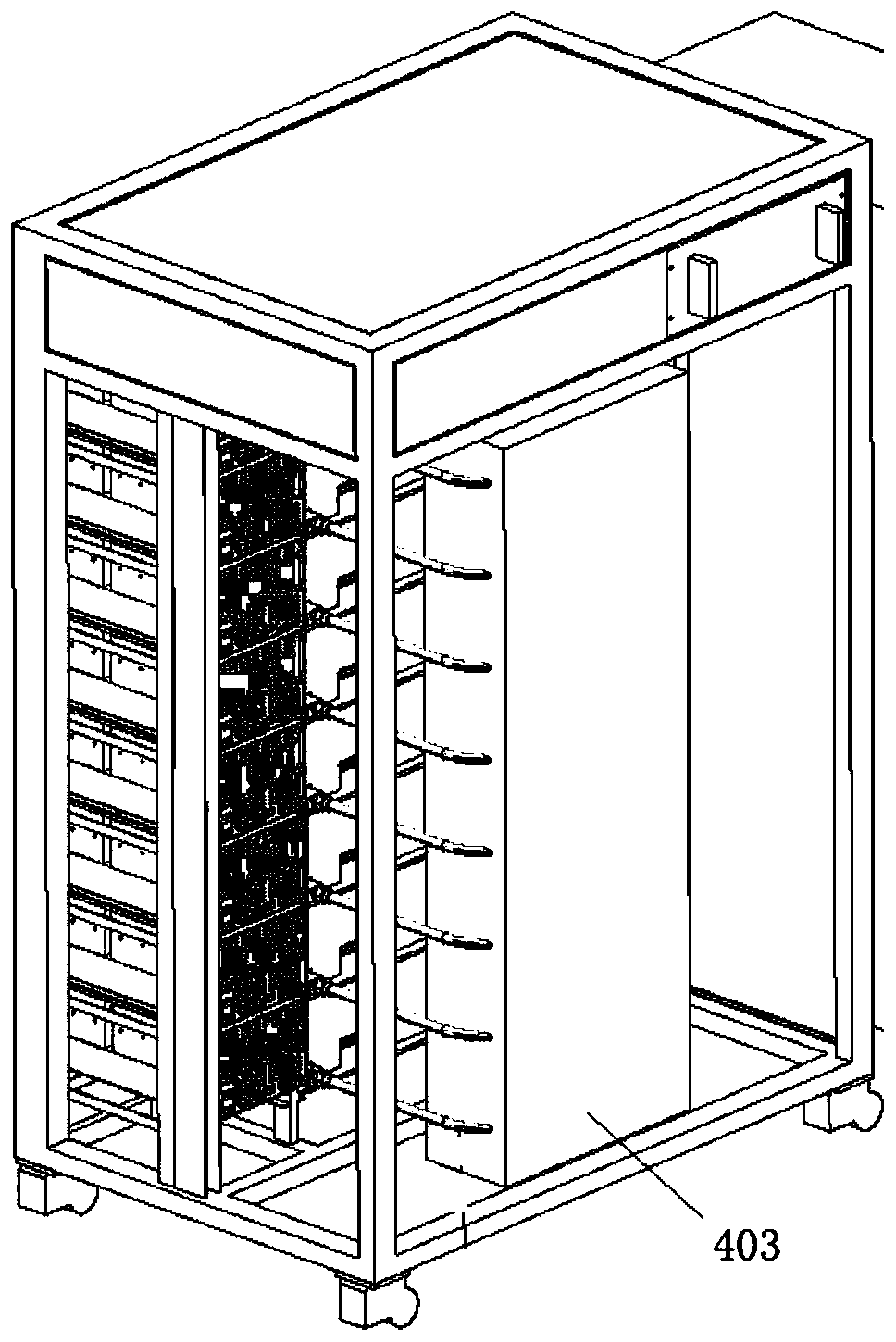

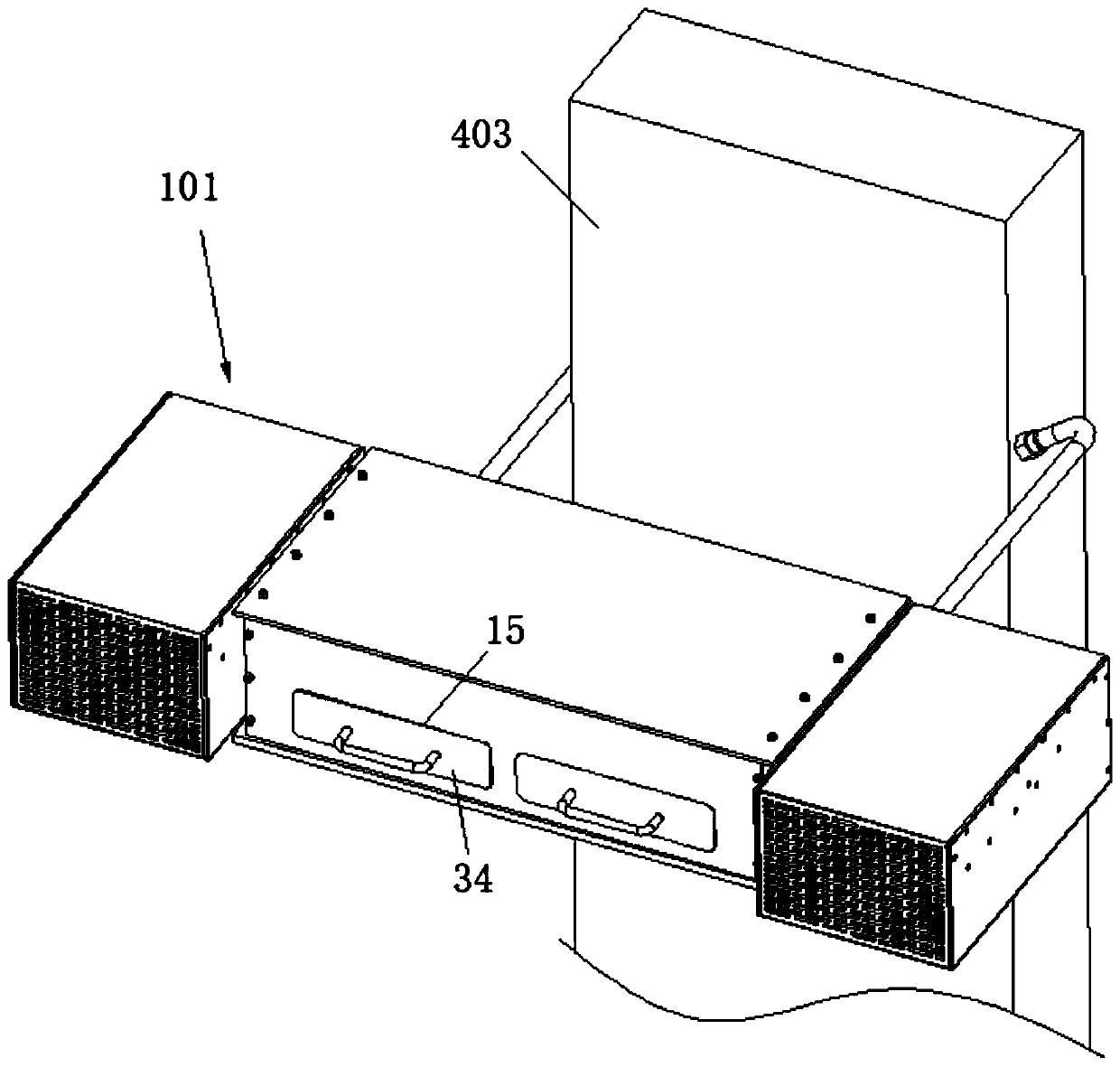

[0038] Embodiment 1: A kind of reliability test equipment of high-power laser chip, refer to attached Figure 1-9 , including a test carrier 1, a connection block 3 and a control assembly 101, the control assembly 101 includes a power supply module and a test module, the power supply module is used for chip power supply, and the test module is used for data collection and transmission of chip testing, A carrier board 2 is installed on the test platform 1, and a plurality of chip slots 201 for chip embedding are provided on the carrier board 2. There are several wires 21 connected to the chip on the carrier board 2, and these wires 21 are placed on the An electrical connector 22 is formed at one end of the carrier board 2, and a connection port 31 for inserting the power supply connector 22 is opened on the connection block 3, and the connection block 3 is electrically connected with the control assembly 101;

[0039] A cooling box 4 is arranged directly below the carrier plate...

Embodiment 2

[0046] Embodiment 2: a kind of reliability test equipment of high-power laser chip, refer to attached Figure 1-9 , including a test carrier 1, a connection block 3 and a control assembly 101, the control assembly 101 includes a power supply module and a test module, the power supply module is used for chip power supply, and the test module is used for data collection and transmission of chip testing, A carrier board 2 is installed on the test platform 1, and a plurality of chip slots 201 for chip embedding are provided on the carrier board 2. There are several wires 21 connected to the chip on the carrier board 2, and these wires 21 are placed on the An electrical connector 22 is formed at one end of the carrier board 2, and a connection port 31 for inserting the power supply connector 22 is opened on the connection block 3, and the connection block 3 is electrically connected with the control assembly 101;

[0047] A cooling box 4 is arranged directly below the carrier plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com