Embedded-type chemical wax removing ball as well as preparation method and application thereof

A wax removal ball and chemical technology, applied in the direction of chemical instruments and methods, mechanical equipment, drilling compositions, etc., can solve the problems of pipe jamming, manpower, material resources, financial resources waste, rubber balls without wax-proof effect, etc., to achieve Reduce dosing cost, reduce dosing cycle and improve wax removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] An embedded chemical wax removal ball and a preparation method thereof, in terms of parts by mass, its raw material components and dosage are as follows:

[0042] 40 parts of EVA; 40 parts of sodium stearate; 8 parts of sodium benzoate; 7 parts of sodium laurate; 4.7 parts of gemini surfactant 1,4-butane sultone; 0.3 parts of coloring agent.

[0043] Preparation Process

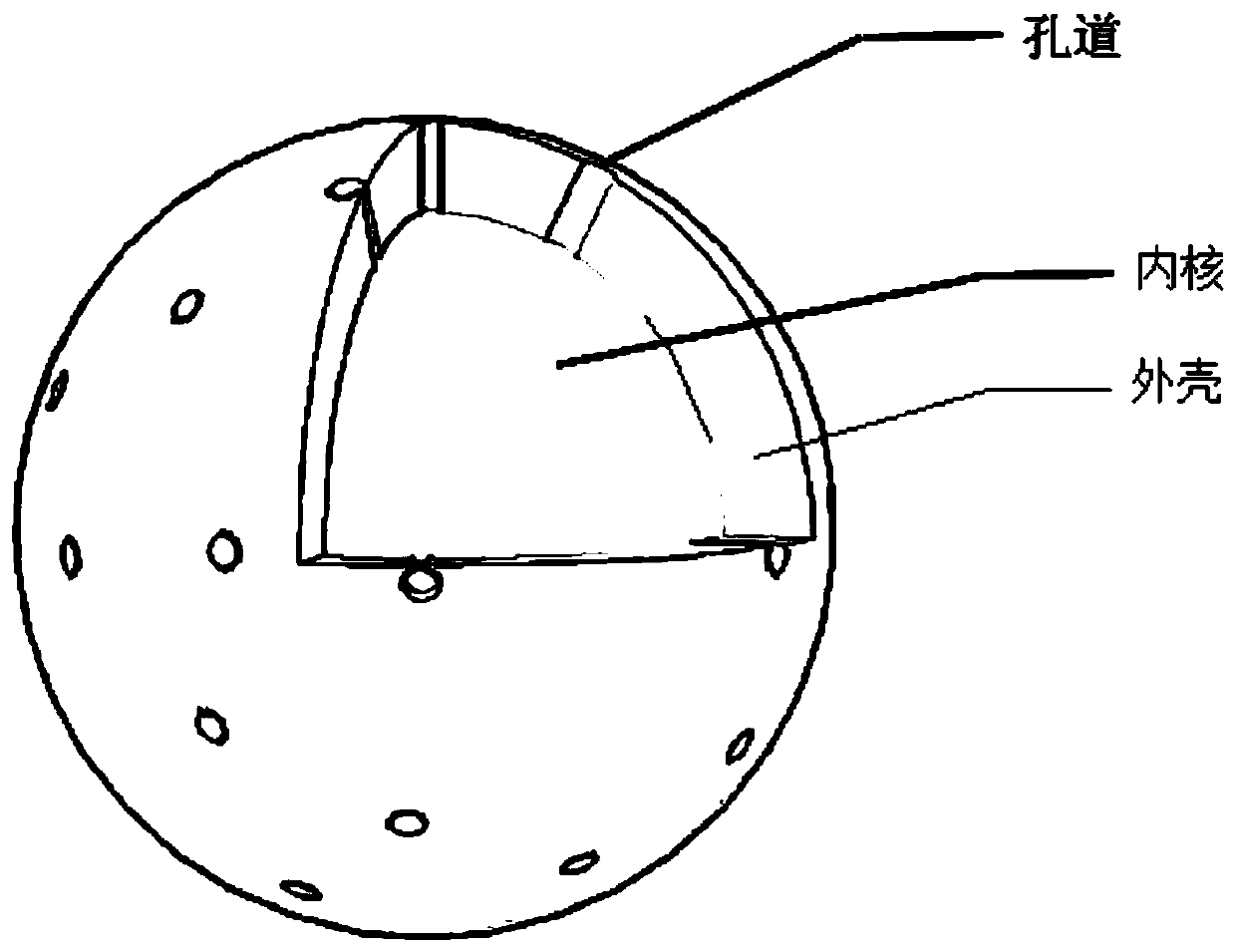

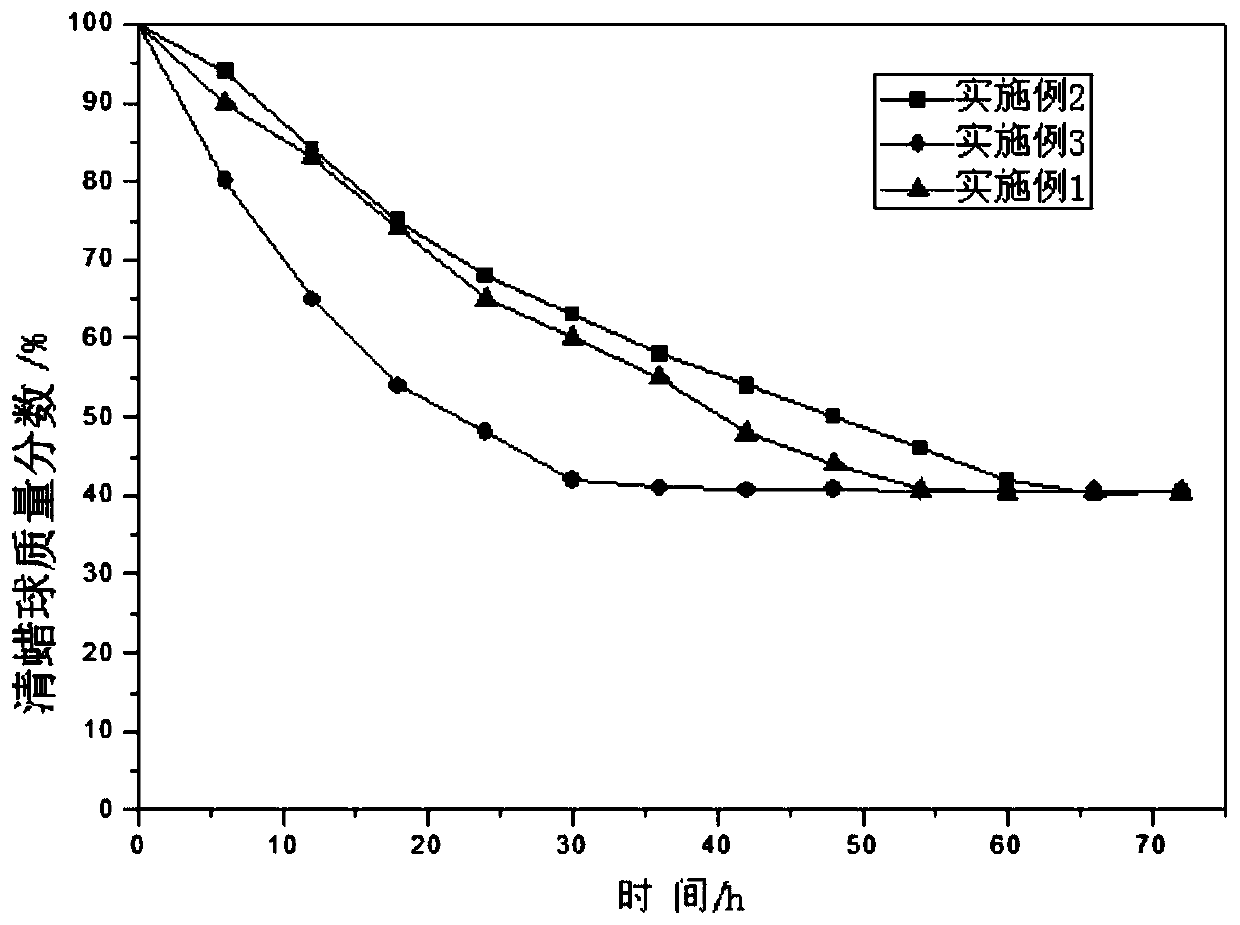

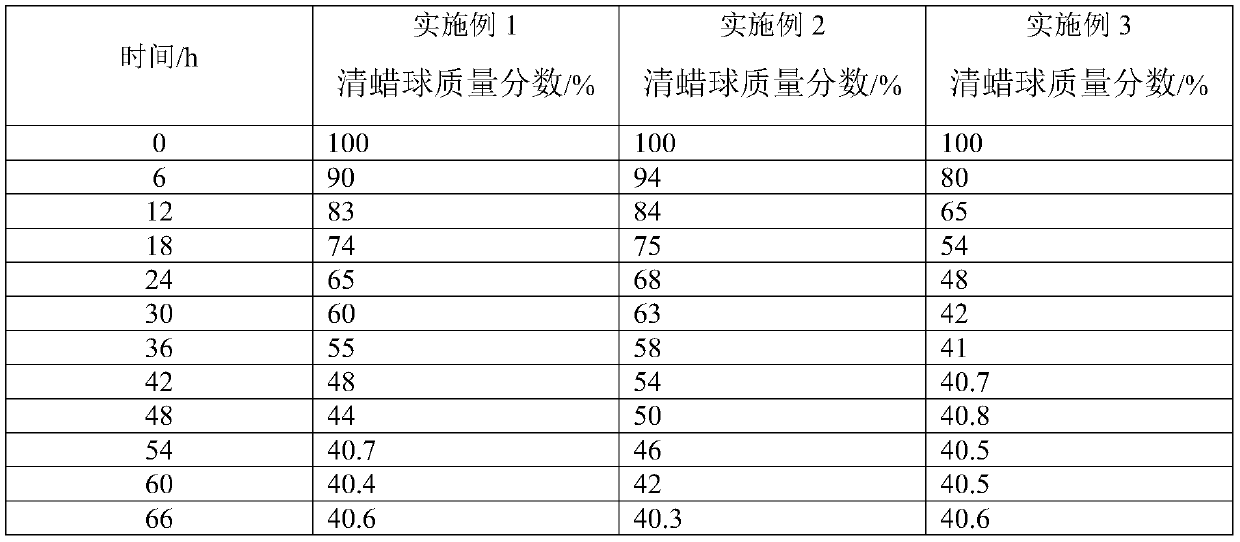

[0044] Take a certain quality of medicine according to the formula, dissolve sodium stearate, sodium benzoate, gemini surfactant, and sodium laurate in absolute ethanol, mix evenly, prepare solid particles with a diameter of 38 mm, and dry. Heat to 75°C to melt the EVA, mix it evenly with the colorant, adhere to the surface of the prepared solid particles, and use a stainless steel spherical mold for cooling and molding. Evenly punch 14 holes with a diameter of 3 mm and a depth of 3.5 mm on the surface of the prepared wax removal ball to penetrate the EVA shell. After the pitching test, the active co...

Embodiment 2

[0046] In parts by mass, 50 parts of EVA; 35 parts of sodium stearate; 3 parts of sodium benzoate; 7 parts of sodium laurate; 4.7 parts of gemini surfactant 1,4-butane sultone; 0.3 parts of coloring agent.

[0047] Preparation Process

[0048]Take a certain quality of medicine according to the formula, dissolve sodium stearate, sodium benzoate, gemini surfactant, and sodium laurate in absolute ethanol, mix evenly, prepare solid particles with a diameter of 40 mm, and dry. The EVA is melted at 78°C, mixed evenly with the coloring agent, attached to the surface of the prepared solid particles, and cooled and formed using a stainless steel spherical mold. Evenly drill 12 holes with a diameter of 2 mm and a depth of 2.5 mm on the surface of the prepared wax removal ball to penetrate the EVA shell. After the pitching test, the active components were completely dissolved, and the EVA shell was cleaned, and sodium stearate, sodium benzoate, gemini surfactant, and sodium laurate were...

Embodiment 3

[0050] 45 parts of EVA; 37 parts of sodium stearate; 5 parts of sodium benzoate; 7 parts of sodium laurate; 4.7 parts of gemini surfactant 1,4-butane sultone; 0.3 parts of coloring agent.

[0051] Preparation Process

[0052] Take a certain quality of medicine according to the formula, dissolve sodium stearate, sodium benzoate, gemini surfactant, and sodium laurate in absolute ethanol, mix evenly, prepare solid particles with a diameter of 39 mm, and dry. The EVA is melted at 80°C, mixed evenly with the coloring agent, attached to the surface of the prepared solid particles, and cooled and formed using a stainless steel spherical mold. Evenly punch 16 holes with a diameter of 4 mm and a depth of 3 mm on the surface of the prepared wax removal ball to penetrate the EVA shell. After the pitching test, the active components were completely dissolved, and the EVA shell was cleaned, and sodium stearate, sodium benzoate, gemini surfactant, and sodium laurate were weighed according ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com