A kind of photocurable ink and pcb board

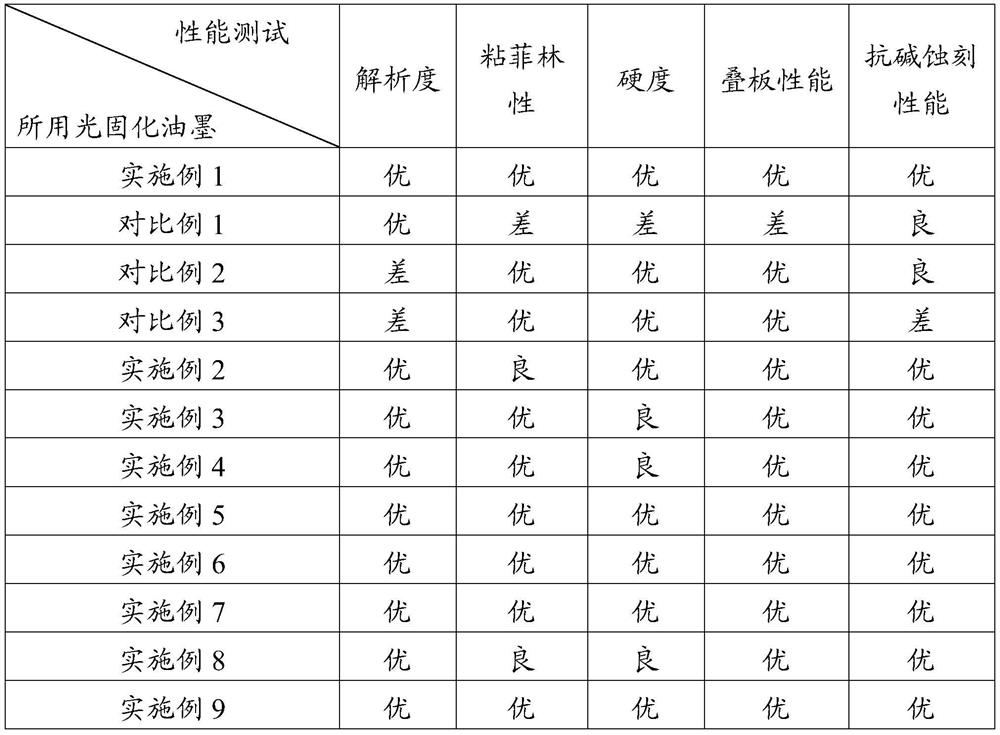

A light-curing ink and carboxylation technology, applied in ink, optics, opto-mechanical equipment, etc., can solve the problems of poor alkaline etching resistance of protective layer, difficulty in meeting high-precision requirements for PCB board manufacturing, and poor resolution of ink layer. , to achieve the effect of good resistance to alkaline etching, excellent resolution, and slow development speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0119] This embodiment provides a photocurable ink, which includes the following components in parts by weight: 20 parts of carboxylated modified epoxy acrylate resin, 2 parts of (meth)acrylic copolymer resin, trimethylol 3 parts of propane tri(meth)acrylate, 2 parts of 2-methyl-1-(4-methylthiophenyl)-2-morpholino-1-acetone, 30 parts of talc, propylene glycol methyl ether acetate 39 parts, 2 parts of phthalocyanine blue, 1 part of leveling agent, 1 part of defoamer.

[0120] Among them, the (meth)acrylic acid copolymer resin is formed by copolymerization of acrylic acid with a mass fraction of 20% and methyl methacrylate with 80% respectively, with a weight average molecular weight of 30,000, a molecular weight distribution index of 1.95, and an acid value of 90 mgKOH / g. The Tg point is 110°C.

[0121] Carboxylation modified epoxy acrylate resin is carried out ring-opening reaction by o-methyl novolak epoxy of CYDCN-200 model and (meth)acrylic acid to generate novolac epoxy a...

Embodiment 2

[0134] The present embodiment provides a photocurable ink, which includes the following components in parts by weight: 15 parts of carboxylated modified epoxy acrylate resin, 10 parts of (meth)acrylic acid copolymer resin, dipentaerythritol hexa( 2 parts of methacrylate, 6 parts of benzoin dimethyl ether, 2 parts of 2-isopropyl thioxanthone, 20 parts of silicon dioxide, 35 parts of propylene glycol methyl ether acetate, 5 parts of phthalocyanine green, leveling 1 part of agent, 1 part of adhesion promoter, 3 parts of defoamer.

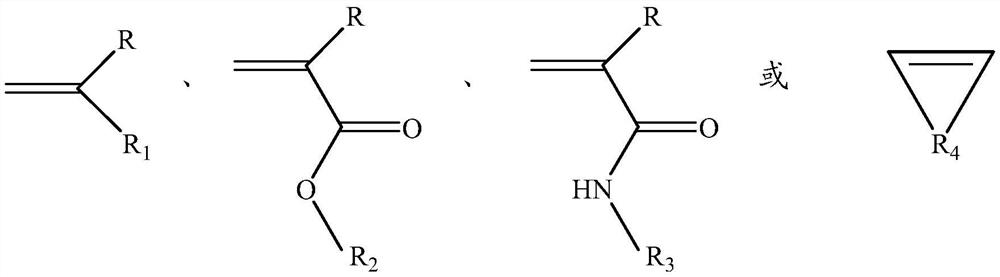

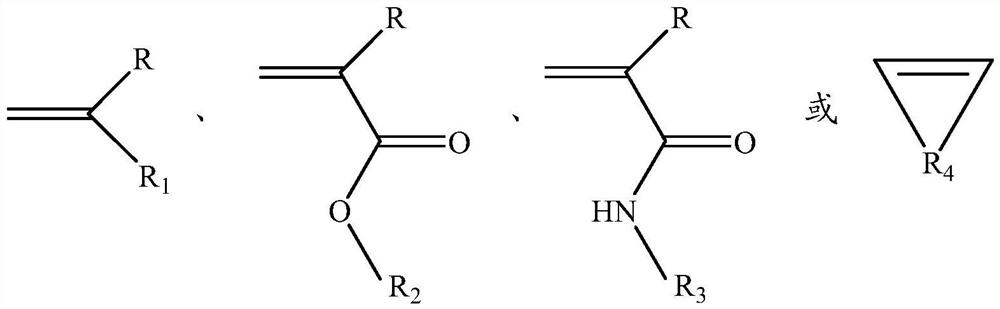

[0135] Among them, the (meth)acrylic acid copolymer resin is formed by copolymerization of 8% methacrylic acid, 82% methyl acrylate and 10% cyclopentene, with a weight average molecular weight of 20000, a molecular weight distribution index of 1.70, and an acid value of 50 mgKOH / g, the Tg point is 80°C, the total mass of methacrylic acid, methyl acrylate and cyclopentene is 100%, the mass fraction of methacrylic acid is 8%, the mass fraction of methyl...

Embodiment 3

[0138] This embodiment provides a photocurable ink, which includes the following components in parts by weight:

[0139] 35 parts of carboxylated modified epoxy acrylate resin, 1 part of (meth)acrylic acid copolymer resin, 2.8 parts of trimethylolpropane tri(meth)acrylate, 1,6-hexanediol di(meth)acrylic acid 1 part of ester, 2.8 parts of 2-methyl-1-(4-methylthiophenyl)-2-morpholino-1-propanone, 1 part of benzoin ethyl ether, 25 parts of kaolin, ethylene glycol mono 30 parts of methyl ether, 0.1 part of azo yellow, and 0.1 part of defoamer.

[0140] Among them, the (meth)acrylic copolymer resin is formed by copolymerization of 25% acrylic acid and 75% methyl methacrylate, with a weight average molecular weight of 60,000, a molecular weight distribution index of 2.02, an acid value of 140 mgKOH / g, and a Tg point of 105 °C, based on the total mass of acrylic acid and methyl methacrylate as 100%, the mass fraction of acrylic acid is 25%, and the mass fraction of methyl methacryla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com