A kind of multi-temperature zone control method of high molecular weight polycarbosilane bridge synthesis

A polycarbosilane bridge and high molecular weight technology is applied in the multi-temperature zone control field of high molecular weight polycarbosilane bridge combination, can solve the problems of complex process, low actual production efficiency, low cost, etc., and achieves simple process flow, Reduce time cost and economic cost, the effect of short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

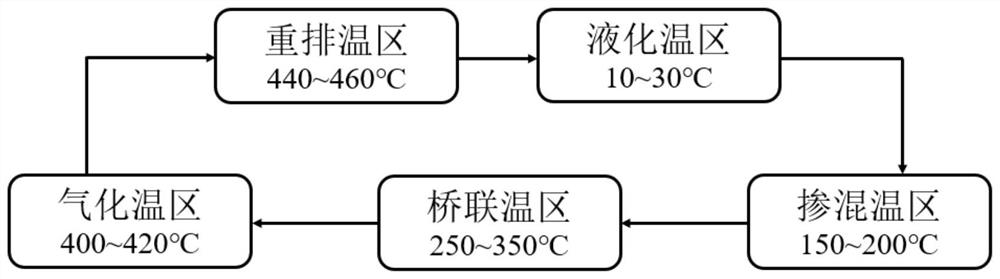

[0055] This embodiment provides a multi-temperature zone control method for high molecular weight polycarbosilane bridging synthesis, comprising the following steps:

[0056] S1: Replace the air in the synthesis unit including the gasification temperature zone, rearrangement temperature zone, liquefaction temperature zone, blending temperature zone and bridging temperature zone with nitrogen with a purity ≥ 99.99%;

[0057] S2: Take 100kg of liquid silane and place it in the vaporization temperature zone, and add 5kg of dimethyldivinylsilane into the mixing temperature zone;

[0058] S3: Heating and controlling the temperature in the five temperature zones respectively to realize vaporization of low molecular weight liquid silane, rearrangement of low molecular weight liquid silane, liquefaction of low molecular weight liquid silane, blending of low molecular weight liquid silane and bridging agent and low molecular weight liquid silane The purpose of bridging; the temperature...

Embodiment 2

[0068] This embodiment provides a multi-temperature zone control method for high molecular weight polycarbosilane bridging synthesis, comprising the following steps:

[0069] S1: Replace the air in the synthesis device including the gasification temperature zone, rearrangement temperature zone, liquefaction temperature zone, blending temperature zone and bridging temperature zone with argon with a purity ≥ 99.99%;

[0070] S2: Take 100kg of liquid silane and place it in the vaporization temperature zone, and add 7kg of divinylsilane into the mixing temperature zone;

[0071] S3: Heating and controlling the temperature in the five temperature zones respectively to realize vaporization of low molecular weight liquid silane, rearrangement of low molecular weight liquid silane, liquefaction of low molecular weight liquid silane, blending of low molecular weight liquid silane and bridging agent and low molecular weight liquid silane The purpose of bridging; the temperatures in the ...

Embodiment 3

[0078] This embodiment provides a multi-temperature zone control method for high molecular weight polycarbosilane bridging synthesis, comprising the following steps:

[0079] S1: Replace the air in the synthesis device including the gasification temperature zone, rearrangement temperature zone, liquefaction temperature zone, blending temperature zone and bridging temperature zone with argon with a purity ≥ 99.99%;

[0080] S2: Take 100kg of liquid silane and place it in the vaporization temperature zone, and add 8kg of methyldivinylsilane into the mixing temperature zone;

[0081] S3: Heating and controlling the temperature in the five temperature zones respectively to realize vaporization of low molecular weight liquid silane, rearrangement of low molecular weight liquid silane, liquefaction of low molecular weight liquid silane, blending of low molecular weight liquid silane and bridging agent and low molecular weight liquid silane The purpose of bridging; the temperature in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com