Bismuth phosphate cathode material with stable cycle performance for lithium battery and preparation method thereof

A technology of cycle performance and cathode material, applied in battery electrodes, lithium storage batteries, nanotechnology for materials and surface science, etc., can solve the problems of high reaction activation energy, the cycle performance of cathode materials needs to be improved, and achieve low energy consumption , improve the cycle stability, reduce the effect of the formation of dense crystal form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

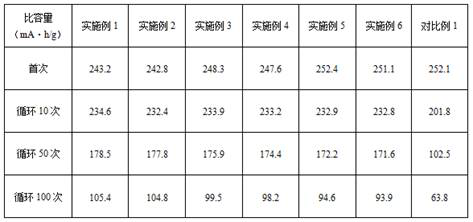

Examples

Embodiment 1

[0028] (1) Add 0.96mol of bismuth nitrate pentahydrate into 6.4L of dilute nitric acid with a pH value of 2, and stir at room temperature until completely dissolved to obtain a bismuth source solution; In nitric acid, heat to 150°C and keep stirring until it is completely dissolved to obtain a tellurium source solution; add 1.013mol of ammonium phosphate to 8.5L deionized water, and stir at room temperature until completely dissolved to obtain a phosphorus source solution;

[0029] (2) Add the tellurium source solution into the bismuth source solution and stir to mix evenly, then add 0.04mol o-dichlorobenzene, ultrasonically disperse for 25 minutes, then add the phosphorus source solution, add phosphoric acid solution dropwise to adjust the pH value to 2.5, and introduce hydrogen sulfide gas, placed in a constant temperature water bath at 45°C, continued ultrasonic oscillation for 45 minutes, and then filtered and washed to obtain Te 4+ doped BiPO 4 Precursor;

[0030] (3) P...

Embodiment 2

[0032] (1) Add 0.48mol of bismuth sulfate heptahydrate into 3.2L of dilute nitric acid with a pH value of 2, and stir at room temperature until completely dissolved to obtain a bismuth source solution; In nitric acid, heat to 150°C and keep stirring until it is completely dissolved to obtain a tellurium source solution; add 1.013mol potassium phosphate to 8.5L deionized water, and stir at room temperature until completely dissolved to obtain a phosphorus source solution;

[0033] (2) Add the tellurium source solution into the bismuth source solution and stir to mix evenly, then add 0.04mol o-dichlorobenzene, ultrasonically disperse for 20 minutes, then add the phosphorus source solution, add phosphoric acid solution dropwise to adjust the pH value to 2, and introduce hydrogen sulfide gas, placed in a constant temperature water bath at 50°C, continued ultrasonic oscillation for 60 min, and then filtered and washed to obtain Te 4+ doped BiPO 4 Precursor;

[0034] (3) Put the p...

Embodiment 3

[0036] (1) Add 0.97mol of bismuth nitrate pentahydrate into 6.5L of dilute nitric acid with a pH value of 2, stir at room temperature until completely dissolved to obtain a bismuth source solution; add 0.03mol of potassium tetrahydrogen tellurate into 1L of dilute nitric acid with a pH value of 2 , heated to 150°C and kept stirring until it was completely dissolved to obtain a tellurium source solution; add 1.01mol of sodium phosphate to 7.8L deionized water and stir at room temperature until completely dissolved to obtain a phosphorus source solution;

[0037] (2) Add the tellurium source solution into the bismuth source solution and stir to mix evenly, then add 0.04mol o-dichlorobenzene, ultrasonically disperse for 30 minutes, then add the phosphorus source solution, add phosphoric acid solution dropwise to adjust the pH value to 3, and introduce hydrogen sulfide gas, placed in a constant temperature water bath at 40°C, continued ultrasonic oscillation for 40 min, and then fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com