A hybrid fiber reinforced toughened high-strength self-compacting concrete and its preparation method

A self-compacting concrete and hybrid fiber technology, which is applied in the field of concrete to achieve the effects of improving fluidity, increasing fluidity and improving pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0031] A hybrid fiber-reinforced toughened high-strength self-compacting concrete, in which 0.03% to 0.09% of the volume of the concrete matrix is mixed with nano-carbon fibers and 0.6% to 0.9% of the volume of the concrete matrix is copper-coated microwire steel fibers. The weight fraction is composed of: per 100 parts of concrete matrix, 35-37 parts of coarse aggregate, 31-33 parts of fine aggregate, 17-18 parts of cement, 4-6 parts of fly ash, 2-3 parts of silica fume, water reducing 0.4-0.6 parts of agent and 5-7 parts of water.

[0032] In the aforementioned hybrid fiber reinforced and toughened high-strength self-compacting concrete, the volume content of the nano-carbon fibers is 0.03% to 0.09%. When the volume content of the nano-carbon fibers exceeds the upper limit of the above range, the fibers will be unevenly dispersed and cannot Play a good role in modifying. The volume content of the copper-coated microwire steel fiber is 0.6% to 0.9%. When the volume conte...

Embodiment 1

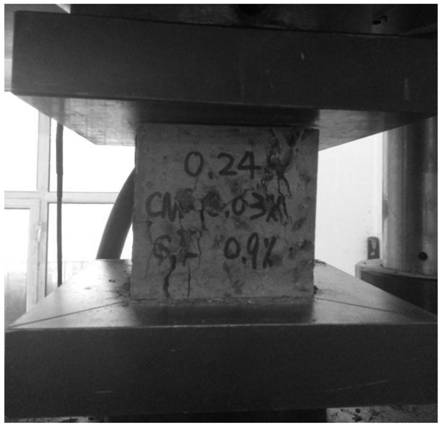

[0042] Compressive strength test: In this embodiment, 5 groups of test pieces were made, of which 1 group without adding any fiber was used as the control group, and 4 groups of fiber concrete were used as the test group. The weight fraction of matrix concrete is as follows: per 100 parts of concrete, 36 parts of coarse aggregate, 32 parts of fine aggregate, 18 parts of cement, 5 parts of fly ash, 2.5 parts of silica fume, 0.5 parts of water reducing agent and 6 parts of water.

[0043] The compressive strength test uses a cube with a side length of 100mm, and each group makes 6 specimens. The test groups and test results are as follows:

[0044]

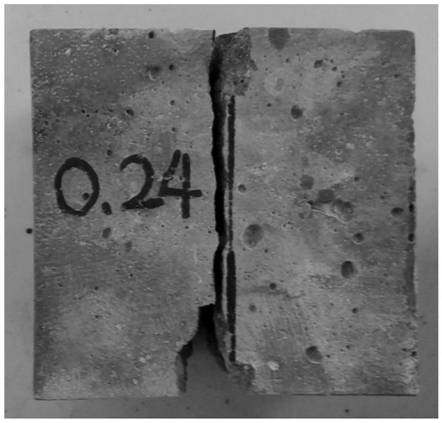

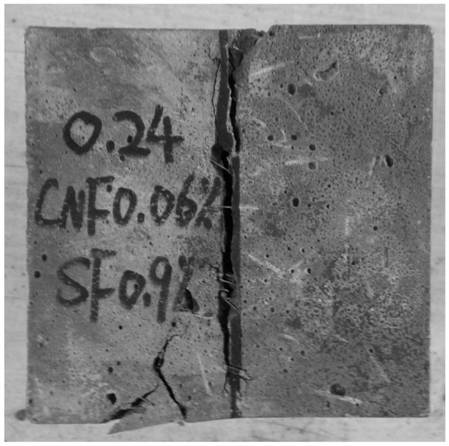

[0045] From the test data in the table, it can be seen that the present invention can give full play to the beneficial effect of the hybrid fiber through appropriate raw material and hybrid fiber ratio, thereby greatly improving the cubic compressive strength of concrete, which is 16.86% and 11.97% higher than ordinary concrete resp...

Embodiment 2

[0047] Splitting tensile strength: In this embodiment, 5 groups of test pieces were made, of which 1 group without adding any fiber was used as the control group, and 4 groups of fiber concrete were used as the test group.

[0048] The matrix concrete mix ratio is the same as in Example 1.

[0049] The splitting tensile strength test uses a cube with a side length of 100mm, and each group makes 6 specimens. The test groups and test results are as follows:

[0050]

[0051]

[0052] As can be seen from the test data in the table, the present invention can give full play to the beneficial effect of the hybrid fiber through appropriate raw material and hybrid fiber ratio, thereby greatly improving the splitting tensile strength of concrete, which is 29.17% higher than ordinary concrete, respectively. 50.93%, 47.39%, and 57.00%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com