Coal-based graphite microcrystal conductive compound and preparation method and application thereof

A technology of graphite microcrystals and composites, which is applied in the direction of circuits, electrical components, battery electrodes, etc., can solve the problems that restrict the wide application of coal-based carbon materials, the conductivity of coal-based carbon materials is not high, and the unfavorable full infiltration of electrolyte, etc. Achieve excellent rate and cycle performance, low price, and improve conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

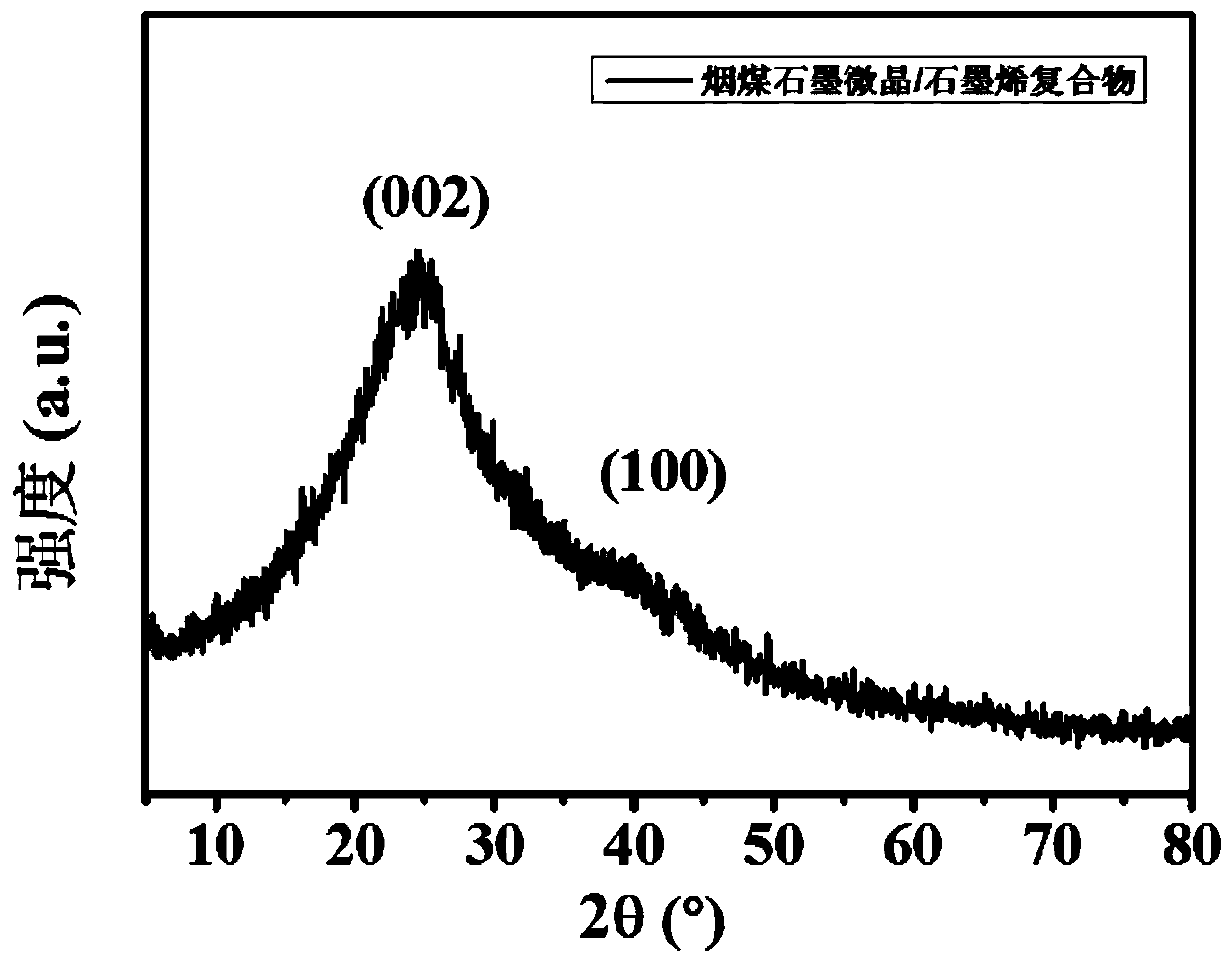

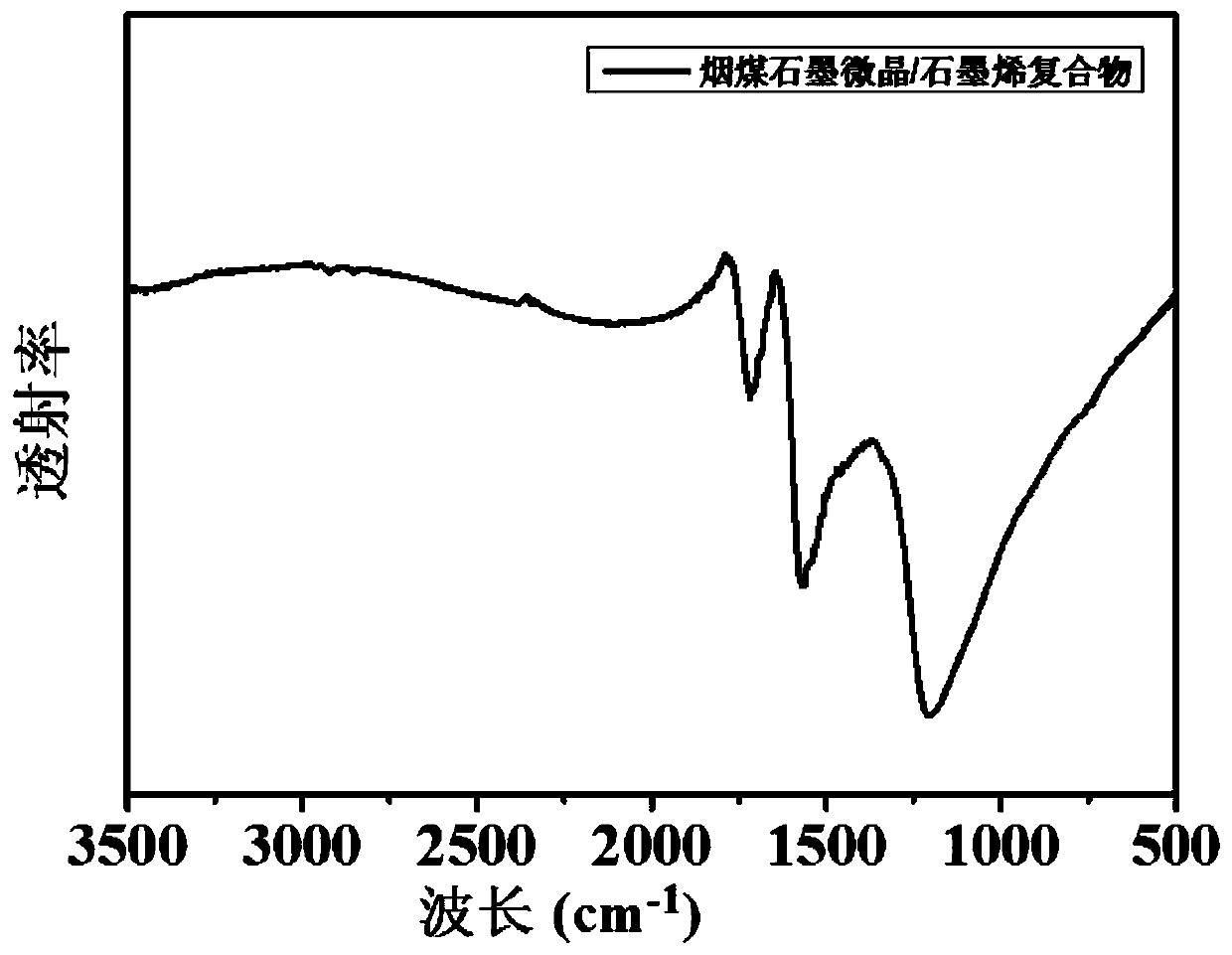

[0027] The bituminous coal was pulverized to obtain precursor particles with a particle size of 200 mesh. Under an ice-water bath, 5 g of bituminous coal particles were slowly stirred and added to 100 mL of mixed acid (VHNO 3 :VH 2 SO 4 =1:4) in the beaker. Raise the temperature to 80 °C and stir the reaction for 8 h, then cool to room temperature and dilute with water. The mixture was centrifuged at 3000 rpm for 3 min to collect oxidized coal samples. Then place it in a dialysis bag for dialysis treatment and wash until neutral. Then the sample was centrifuged at 10,000 rpm for 5 min, the suspension was selected, and dried at 60 °C for 48 h to obtain a graphite oxide microcrystalline sample. According to the mass ratio of 1:2, the graphene oxide and the prepared graphite oxide microcrystal samples were ultrasonically mixed at room temperature for 60 min to prepare a uniform mixed solution. The mixed solution was vacuum freeze-dried for 36 h to obtain a composite gel of g...

Embodiment 2

[0033] The anthracite was pulverized to obtain 100-mesh precursor particles. Under an ice-water bath, 5 g of anthracite particles were slowly stirred and added to 100 mL of mixed acid (VHNO 3 :VH 2 SO 4=1: 5) in the beaker. Raise the temperature to 70 °C and stir the reaction for 10 h, then cool to room temperature and dilute with water. The mixture was centrifuged at 4000 rpm for 5 min to collect oxidized coal samples. Then place it in a dialysis bag for dialysis treatment and wash until neutral. Then the sample was centrifuged at 11000 rpm for 5 min, the suspension was selected, and dried at 80 °C for 36 h to obtain a graphite oxide microcrystalline sample. According to the mass ratio of 1:2, the carboxylated carbon nanotubes and the prepared graphite oxide microcrystal samples were ultrasonically mixed at room temperature for 120 min to prepare a mixed solution. The mixed solution was vacuum freeze-dried for 36 h to obtain a composite gel of graphite oxide microcrystal...

Embodiment 3

[0037] The coking coal was pulverized to obtain precursor particles with a mesh size of 400 mesh. Under an ice-water bath, 7 g of coking coal particles were slowly stirred and added to 100 mL of mixed acid (VHNO 3 :VH 2 SO 4 =1:3) in the beaker. Raise the temperature to 80 °C and stir the reaction for 10 h, then cool to room temperature and dilute with water. The mixture was centrifuged at 3000 rpm for 5 min to collect oxidized coal samples. Then place it in a dialysis bag for dialysis treatment and wash until neutral. Then the sample was centrifuged at 10,000 rpm for 9 min, the suspension was selected, and dried at 80 °C for 24 h to obtain a graphite oxide microcrystalline sample. According to the mass ratio of 1:2, the water-soluble carbon black and the prepared graphite oxide crystallites were ultrasonically mixed at room temperature for 30 min to prepare a mixed solution. The mixed solution was vacuum freeze-dried for 24 h to obtain a composite gel of graphite oxide m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com