Preparation, product and application of tubular lithium titanate/titanium dioxide composites with regular defects

A composite material, titanium dioxide technology, applied in the direction of secondary batteries, electrochemical generators, structural parts, etc., can solve the problems of unstable electrode capacity density, uneven material mixing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

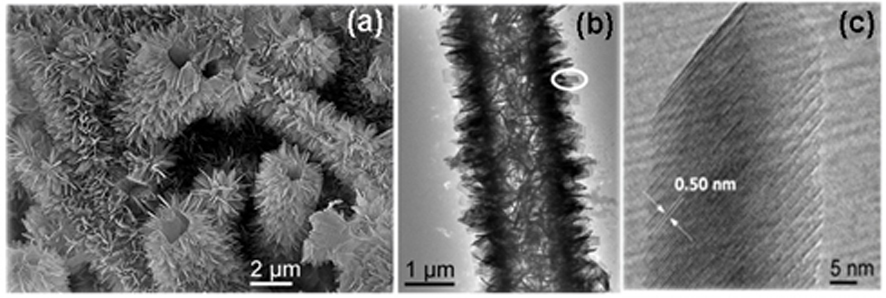

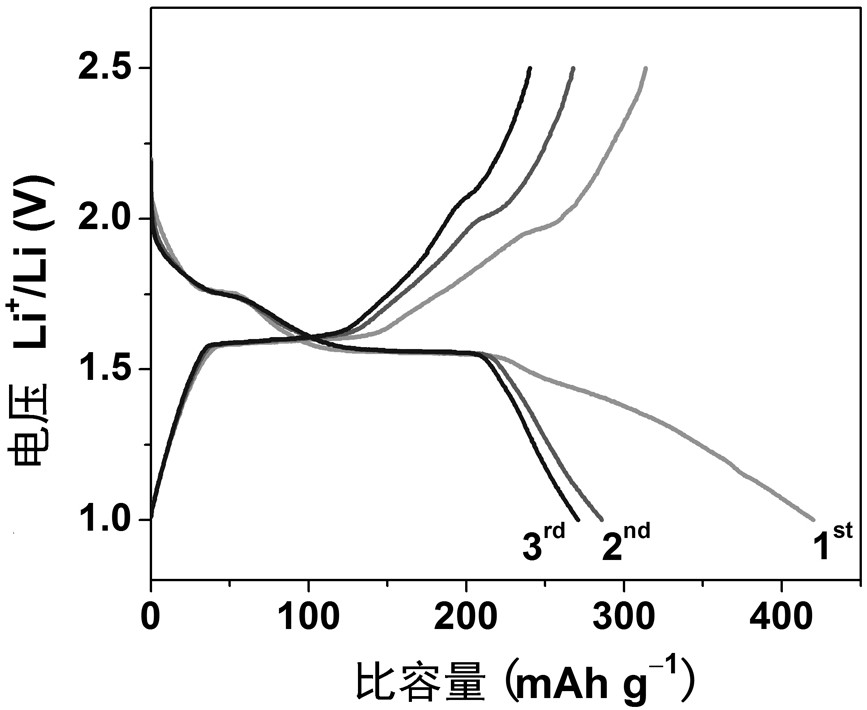

[0023] A method for preparing a tubular lithium titanate / titanium dioxide composite material containing regular defects, using ultraviolet light excitation and hydrothermal method as a technical path, and synthesizing regular-containing nanosheets through the hydrolysis conversion and calcination of ethylene glycol titanium Defective tubular Li 4 Ti 5 O 12 / TiO 2 For composite materials, follow these steps:

[0024] a. Porous amorphous TiO 2 Preparation of rods: Measure 5 ml of n-tetrabutyl titanate dropwise into 200 ml of ethylene glycol, stir at 160 oReflux for 2 h at C temperature to obtain a white ethylene glycol titanium precipitate. The obtained white ethylene glycol titanium was washed several times with ethanol, dispersed in an aqueous solution, and irradiated with ultraviolet light of a 150 W mercury lamp for 4 hours to obtain porous amorphous TiO 2 Great.

[0025] b. Li 4 Ti 5 O 12 / TiO 2 Preparation of tubes: Weigh 0.24 g of the porous amorphous TiO obtai...

Embodiment 2

[0028] A preparation method of a tubular lithium titanate / titanium dioxide composite material containing regular defects, similar to Example 1, is as follows:

[0029] a. Porous amorphous TiO 2 Preparation of rods: Measure 5 ml of n-tetrabutyl titanate dropwise into 300 ml of ethylene glycol, stir at 160 o Reflux for 2 h at C temperature to obtain a white ethylene glycol titanium precipitate. The obtained white ethylene glycol titanium was washed several times with ethanol, dispersed in an aqueous solution, and irradiated with ultraviolet light of a 300 W mercury lamp for 4 hours to obtain porous amorphous TiO 2 Great.

[0030] b. Li 4 Ti 5 O 12 / TiO 2 Preparation of tubes: Weigh 0.36 g of the porous amorphous TiO obtained in step a 2 rod, disperse it into 50 ml of deionized water, and at the same time add 0.18 g of lithium hydroxide, and after stirring for half an hour, transfer the resulting suspension to a stainless steel autoclave containing a teflon lining, at 140 ...

Embodiment 3

[0032] A preparation method of a tubular lithium titanate / titanium dioxide composite material containing regular defects, similar to Example 1, is as follows:

[0033] a. Porous amorphous TiO 2 Preparation of rods: measure 10 ml of n-tetrabutyl titanate dropwise into 400 ml of ethylene glycol, stir at 160 o Reflux for 2 h at C temperature to obtain a white ethylene glycol titanium precipitate. The obtained white ethylene glycol titanium was washed several times with ethanol, dispersed in an aqueous solution, and irradiated with ultraviolet light of a 300 W mercury lamp for 4 hours to obtain porous amorphous TiO 2 Great.

[0034] b. Li 4 Ti 5 O 12 / TiO 2 Preparation of tubes: Weigh 0.72 g of the porous amorphous TiO obtained in step a 2 rod, disperse it into 200 ml of deionized water, and at the same time add 0.14 g of lithium hydroxide, and after stirring for half an hour, transfer the resulting suspension to a stainless steel autoclave containing a teflon lining, at 13...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com