Preparation method of metal-organic framework compound and application thereof

A metal-organic framework and compound technology, which is used in the application field of metal-organic framework compounds and the preparation of cobalt selenide/graphite carbon composite materials, can solve the problems of poor stability during use, insufficient overall distribution, and inability to form homogeneous distribution. , to achieve the effect of uniform size, simple and feasible preparation process, and no deterioration of lithium storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: Preparation of polyhedral metal organic framework compound ZIF-67

[0025] Weigh 4.9mmol Co(NO 3 ) 2 ·6H 2 O and 39.5mmol 2-methylimidazole were dissolved in 100ml methanol respectively, and the stirring speed was set to be 350r / min. After stirring and dissolving completely, the Co(NO 3 ) 2 · 6H 2 The O solution was poured into the 2-methylimidazole solution, stirred for 12 minutes, aged at room temperature for 20 hours after the stirring was stopped, and the product was centrifuged at a speed of 15000 r / min, and the centrifugation time was 5 minutes. After centrifugation, the precipitate was washed with methanol for 3 times. The amount of methanol used was 25 times the mass of the precipitate, and then placed in vacuum at 60°C for 12 hours. The resulting product was the polyhedral metal-organic framework compound ZIF-67.

Embodiment 2

[0026] Example 2: Preparation of cobalt selenide / graphite carbon composite based on MOFs template

[0027] Mix the polyhedral metal-organic framework compound ZIF-67 prepared in Example 1 with Se powder at a mass ratio of 1:1, mix evenly with a mortar, and then place it in a tube furnace under an argon atmosphere to raise the temperature The temperature was raised from room temperature to 800°C at a rate of 5°C / min, and kept at 800°C for 4 hours to obtain a cobalt selenide / graphite carbon composite material.

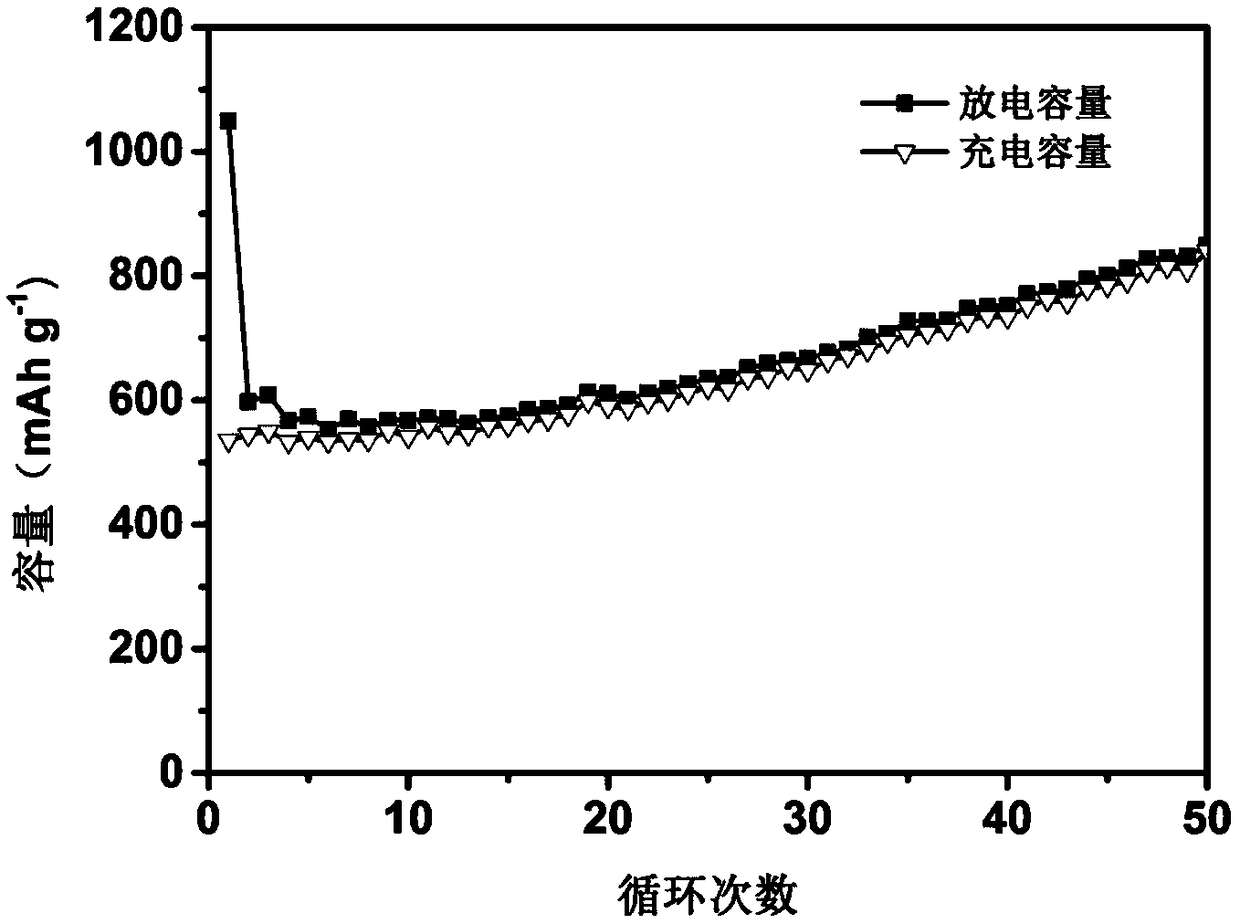

[0028] Experimental result shows: the cobalt selenide / graphitic carbon composite material that the present invention prepares has excellent lithium storage performance, at 100mA g -1 After 50 charge-discharge cycles at the current density, the discharge capacity is 849.12mAh g -1 , indicating that the high specific surface area and porosity provided by the cobalt selenide / graphitic carbon composite material is conducive to increasing the reaction area and promoting the ...

Embodiment 3

[0030] A preparation method for building cobalt selenide / graphite carbon composite material based on MOFs template, comprising the following steps:

[0031] 1) Preparation of polyhedral metal-organic framework compound ZIF-67: Weigh 5.5mmol Co(NO 3 ) 2 ·6H 2 O and 45mmol 2-methylimidazole were dissolved in 100ml methanol respectively, and the stirring speed was set to be 350r / min. After the stirring was completely dissolved, the Co(NO 3 ) 2 · 6H 2The O solution was poured into the 2-methylimidazole solution, stirred for 15 minutes, aged at room temperature for 22 hours after the stirring was stopped, and the product was centrifuged at a speed of 16000 r / min, and the centrifugation time was 3 minutes. After centrifugation, the precipitate was washed with methanol for 3 times. The amount of methanol used is 20 times the mass of the precipitate, and then placed at 60°C for 12 hours in a vacuum. The resulting product is a polyhedral metal-organic framework compound ZIF-67. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com