Magnesium ion battery cathode material of composite core-shell structure and preparation method thereof, and application of magnesium ion battery cathode material of composite core-shell structure

A magnesium-ion battery and cathode material technology, applied in battery electrodes, secondary batteries, structural parts, etc., can solve problems such as charge and discharge capacity and cycle stability limitations, and achieve excellent electrical properties, mild reaction conditions, and structural stability Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

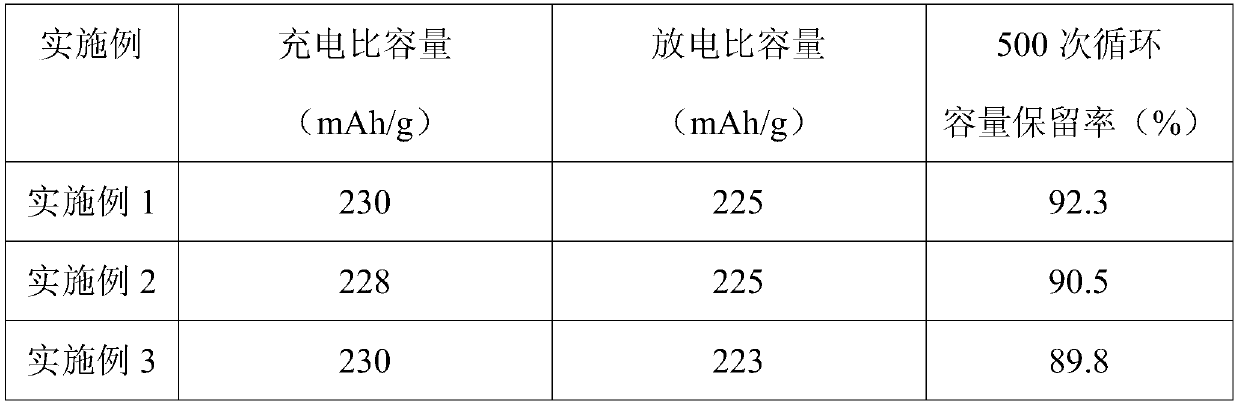

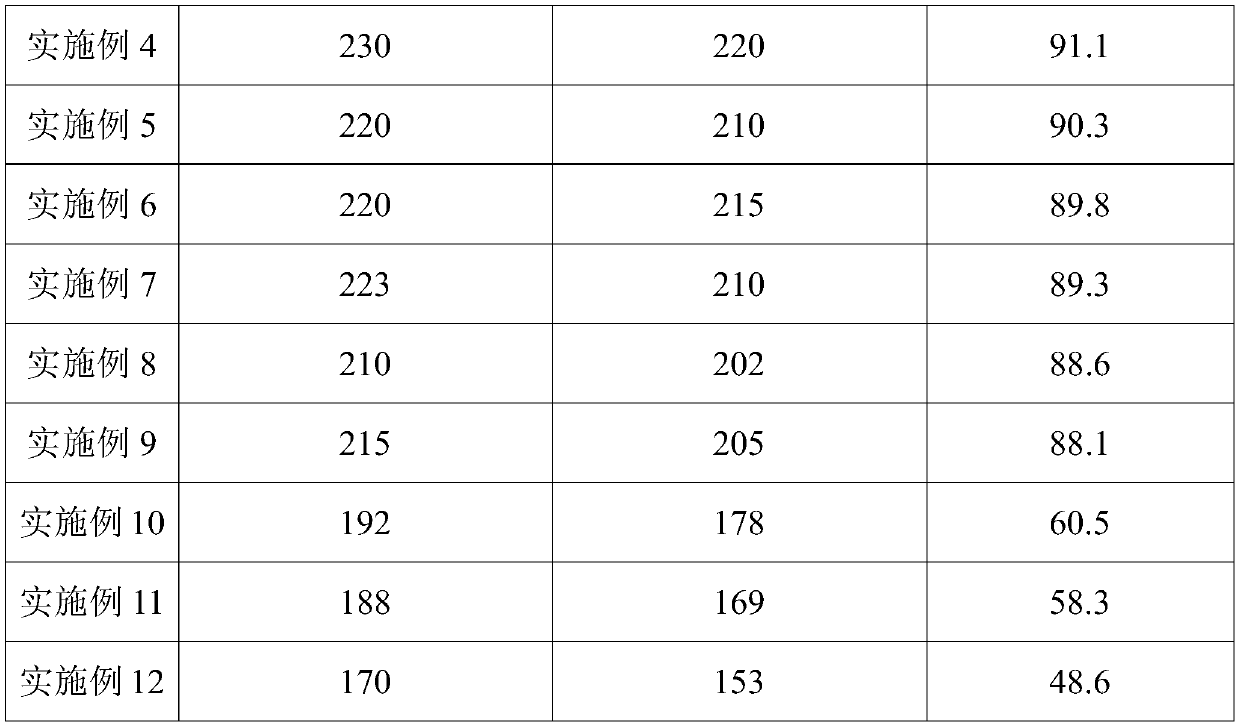

Embodiment 1

[0034] The present embodiment provides a positive electrode material for a magnesium ion battery, which includes a magnesium iron magnesium silicate material as an inner core and a coating vanadium oxide covering the surface of the inner core, and the mass ratio of the vanadium oxide to the iron magnesium silicate is: 0.08:1. Its preparation method comprises the following steps:

[0035] (1) Disperse magnesium iron silicate in deionized water to obtain solution A;

[0036] (2) Dispersing vanadium oxide in solution A obtained in step (1) to obtain solution B;

[0037] (3) The solution B obtained in the step (2) was spray-dried for 5 hours at 110° C. under a nitrogen atmosphere to obtain the positive electrode material for the magnesium ion battery.

[0038]Utilize the prepared magnesium ion battery positive electrode material to manufacture magnesium ion battery and carry out electrochemical performance test, the specific method is: the described magnesium ion battery positiv...

Embodiment 2

[0041] This embodiment provides a kind of anode material of magnesium ion battery, and it comprises the manganese-magnesium silicate of magnesium electric anode material as inner core and the cladding titanium oxide that covers on inner core surface, and the mass ratio of described titanium oxide and manganese-magnesium silicate is 0.1:1. Its preparation method comprises the following steps:

[0042] (1) Disperse manganese magnesium silicate in deionized water to obtain solution A;

[0043] (2) Dispersing titanium oxide in solution A obtained in step (1) to obtain solution B;

[0044] (3) The solution B obtained in the step (2) was spray-dried for 3 hours at 120° C. under an argon atmosphere to obtain the positive electrode material for the magnesium ion battery.

[0045] Utilize the prepared magnesium ion battery positive electrode material to manufacture magnesium ion battery and carry out electrochemical performance test, the specific method is: the described magnesium io...

Embodiment 3

[0048] The present embodiment provides a positive electrode material for a magnesium ion battery, which includes a magnesium electric positive electrode material iron cobalt magnesium silicate as an inner core and a coating titanium oxide covering the surface of the inner core, and the mass of the titanium oxide and iron cobalt magnesium silicate The ratio is 0.2:1. Its preparation method comprises the following steps:

[0049] (1) Disperse iron, cobalt and magnesium silicate in deionized water to obtain solution A;

[0050] (2) Dispersing nickel oxide in solution A obtained in step (1) to obtain solution B;

[0051] (3) The solution B obtained in the step (2) was spray-dried for 10 h at 130° C. under a nitrogen atmosphere to obtain the positive electrode material for the magnesium ion battery.

[0052] Utilize the prepared magnesium ion battery positive electrode material to manufacture magnesium ion battery and carry out electrochemical performance test, the specific metho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com