High-performance air-source drying and moisture sucking integrated machine and system

An air source, high-performance technology, used in dryers, drying, drying gas layout, etc., can solve the problems of difficult control of dehumidification, affecting temperature stability, affecting the utilization rate of waste heat, etc., to ensure stability and uniformity. performance, improve heat utilization rate, and improve the effect of waste heat utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

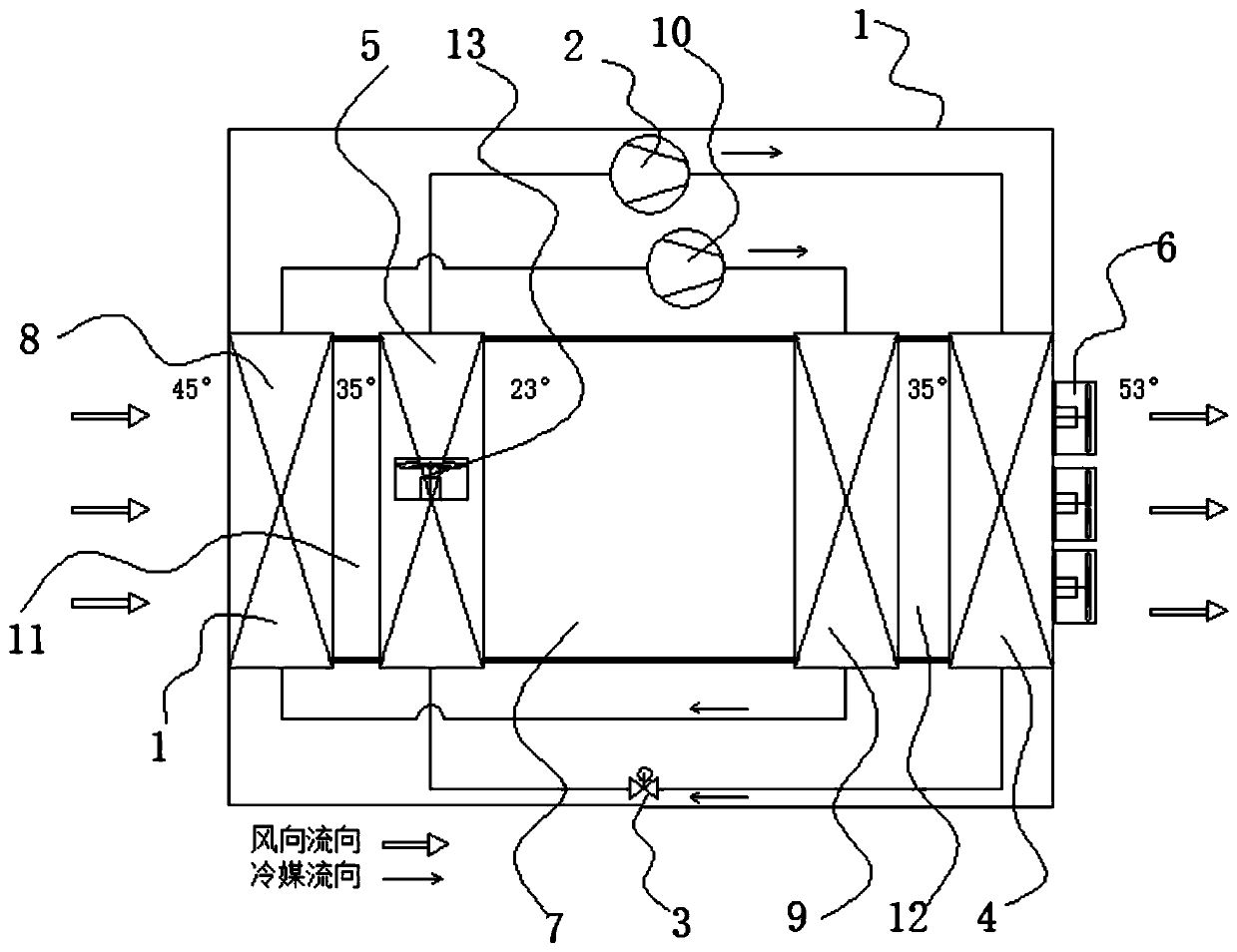

[0029] see figure 1 The high-performance air source drying and dehumidifying integrated machine provided in this embodiment includes a cabinet 1, a compressor 2, a throttle valve 3, a condenser 4, an evaporator 5, an air outlet fan 6 and a heat exchange device. The box body 1 is formed with an air passage 7, the condenser 4 and the evaporator 5 are respectively arranged at the front and rear sections of the air passage 7, and the air outlet fan 6 is arranged corresponding to the condenser 4 for exhausting air. The compressor 2 and the throttle valve 3 are respectively connected to the condenser 4 and the evaporator 5 to form a refrigerant flow cycle from the compressor 2 to the condenser 4 to the throttle valve 3 to the evaporator 5; the heat exchange device includes a pre-cooling Heat exchanger 8, preheating heat exchanger 9 and auxiliary compressor 10, described auxiliary compressor 10 is connected with precooling heat exchanger 8, preheating heat exchanger 9 through pipelin...

Embodiment 2

[0036] This embodiment is basically the same as Embodiment 1, the difference is that:

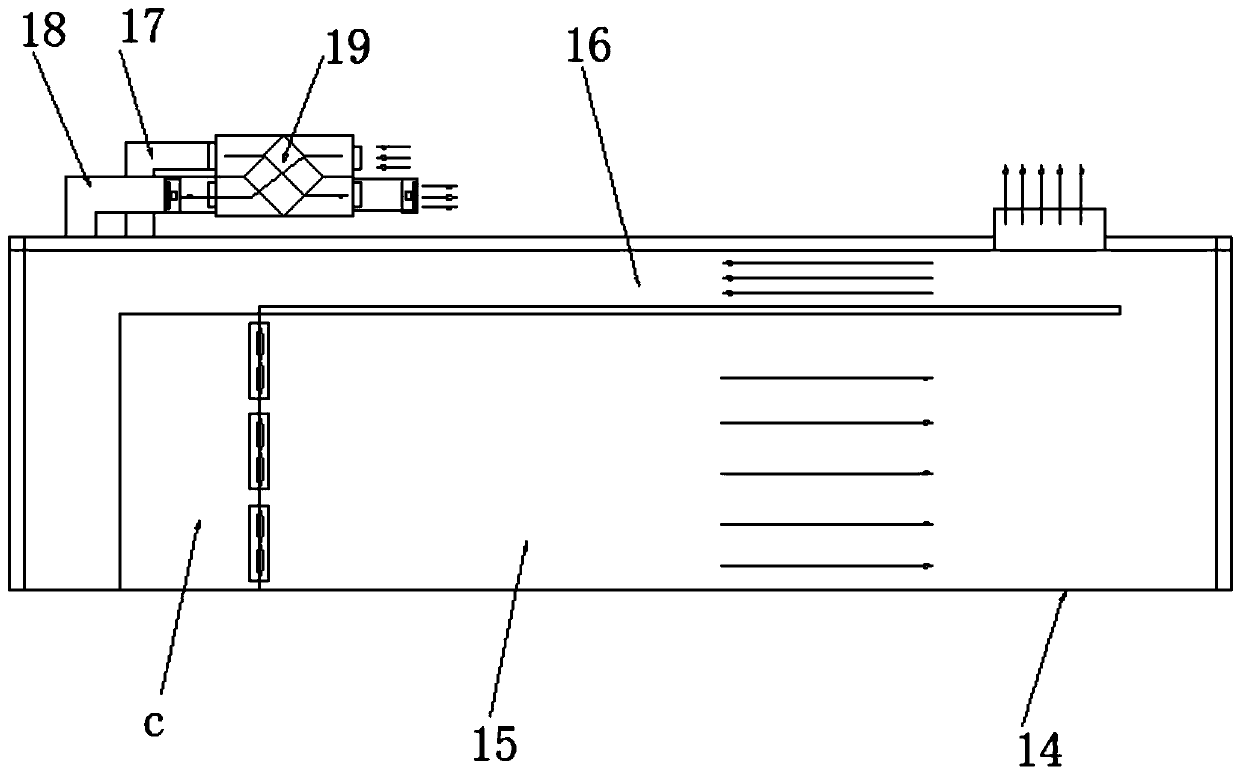

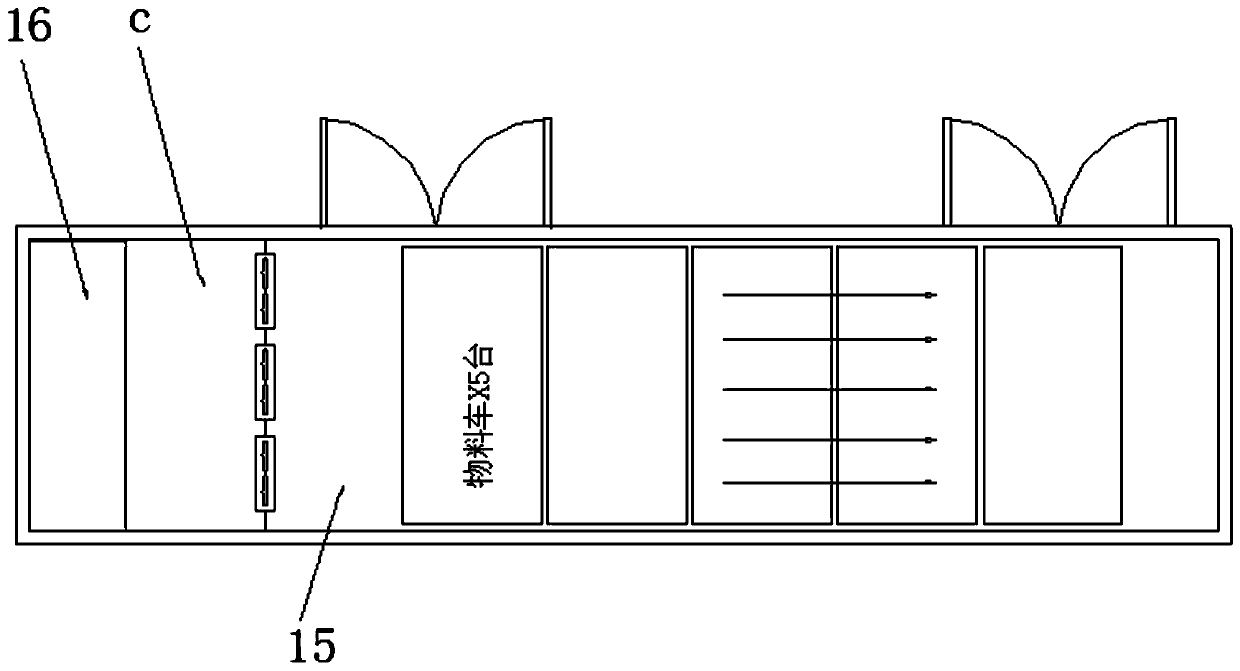

[0037] see Figure 4 to Figure 5 , using the dual-machine heat pump drying system of the high-performance air source drying and dehumidifying integrated machine, including a drying chamber 14, and the drying chamber 14 is provided with a separator 20 in the middle, thereby forming a left and right corresponding first A drying area 15a and a second drying area 15b. The drying chamber 14 is respectively provided with a first air return area 16a and a second air return area 16a connecting the first drying area 15a and the second drying area 15b at the front and rear positions. Wind area 16b, wherein, the front end of the first drying area 15a is provided with a first high-performance air source drying and dehumidifier c1, and the rear end of the second drying area 15b is provided with a second high-performance air source drying machine. The integrated drying and dehumidifying machine c2, the ...

Embodiment 3

[0042] see Image 6 , this embodiment is basically the same as Embodiment 1, the difference is that there is a height difference between the condenser 4 and the evaporator 5, and the position of the condenser 4 is higher than that of the evaporator 5, and the heat exchange The device includes a precooling heat exchanger 8, a preheating heat exchanger 9 and a gravity flow heat pipe 21, the precooling heat exchanger 8 corresponds to the evaporator 5, the preheating heat exchanger 9 corresponds to the condenser 4, and the preheating heat exchanger 9 corresponds to the condenser 4. There is a height difference between the cold heat exchanger 8 and the preheating heat exchanger 9, and the position of the preheating heat exchanger 9 is higher than that of the precooling heat exchanger 8, and the gravity self-flow heat pipe 21 and the precooling heat exchanger 8. The preheating heat exchangers 9 are connected to each other to form a loop, thereby forming a refrigerant flow cycle from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com