Preparation method of structure and function integrated neutron absorbing material

A technology of absorbing materials and functions, applied in the field of radiation protection, can solve the problems of low strength, unsatisfactory dry storage structure and functional integration, and achieve the effects of high density, improved distribution uniformity, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

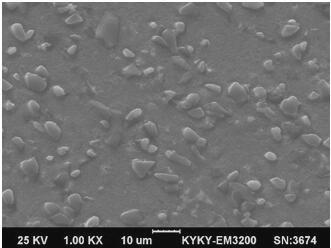

[0034] Weigh 31% boron carbide powder, 1% Y 2 o 3 powder, 68% 6061 aluminum powder, put it into a ball mill tank and mill it for 10 hours, and the ball milling speed is 100 r / min, and finally get a mixed powder; put the mixed powder into a soft mold and use cold isostatic pressing to form it. The compression pressure is 270MPa, and the time is 5min; the cold compact is put into the aluminum sheath, degassed and welded, and the densification treatment is carried out by hot rolling, and the hot rolling temperature is 450°C; the densified neutron absorbing material is heated at 350°C Further hot rolling to the final size; the hot-rolled sheet was annealed at 450° C. for 60 minutes in an air atmosphere to obtain a structural-functional integrated neutron absorbing material. The neutron absorbing plate B prepared in this embodiment 4 C particles are evenly distributed, such as figure 1 As shown, the tensile strength is 326MPa.

Embodiment 2

[0036] Weigh 12% boron carbide powder, 8% Al 2 o 3 powder, 80% 6061 aluminum powder, put it into a ball mill tank and mill it for 25 hours, the ball milling speed is 200 r / min, and finally get a mixed powder; put the mixed powder into a soft mold and use cold isostatic pressing to form, cold isostatic The compression pressure is 120MPa, and the time is 30min; the cold compact is put into the aluminum sheath, degassed and welded, and the densification process is carried out by hot isostatic pressing. The hot isostatic pressing temperature is 550°C, and the time is 20min; The neutron absorbing material was hot-rolled at 450°C to the final size; the hot-rolled plate was annealed at 550°C for 20 minutes in a vacuum atmosphere to obtain a structurally functional integrated neutron absorbing material. The neutron absorbing plate B prepared in this embodiment 4 C particles are evenly distributed, such as figure 2 As shown, the tensile strength is 282MPa.

Embodiment 3

[0038] Weigh 20% boron carbide powder, 10% Zr 2 o 3 powder, 70% 7075 aluminum powder, put it into a ball mill tank and mill it for 2 hours, the ball milling speed is 300 r / min, and finally get a mixed powder; put the mixed powder into a soft mold and use cold isostatic pressing to form, cold isostatic The compression pressure is 200MPa, and the time is 5min; the cold compact is put into the aluminum sheath, degassed and welded, and densified by hot forging, and the hot forging temperature is 600°C; the densified neutron absorbing material is Hot rolling to the final size; the hot-rolled sheet was annealed at 620° C. for 200 min in an argon atmosphere to obtain a structural-functional integrated neutron absorbing material. The neutron absorbing plate B prepared in this embodiment 4 C particle distribution is relatively uniform (such as image 3 shown), the tensile strength can reach 497MPa.

[0039] In the present invention, aluminum alloy may also be used as the raw materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com