Composite wave-absorbing material and preparation method thereof

A technology of composite wave-absorbing materials and composite materials, applied in the field of composite wave-absorbing materials and their preparation, can solve the problems of limited application range, complex preparation process, narrow frequency band, etc., and achieve excellent wave-absorbing performance, high conductivity, and strong absorption intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The embodiment of the present invention provides the first composite wave-absorbing material, the preparation method of which is as follows:

[0050] (1) Weigh the chemicals used, cobalt dichloride hexahydrate, urea, and ammonium fluoride, with a mass of 3.842g, 3.964g, and 0.977g, respectively, and add them to 330mL of distilled water, and ultrasonically stir for 0.5h-1h to form a uniform dispersion solution. Transferred to a hydrothermal reactor, 120 ° C hydrothermal reaction for 5 h, naturally cooled to room temperature, the obtained product was kept at 350 ° C in an argon atmosphere for 2 h, and then naturally cooled to room temperature to obtain 1.446 g of Co 3 o 4 ;

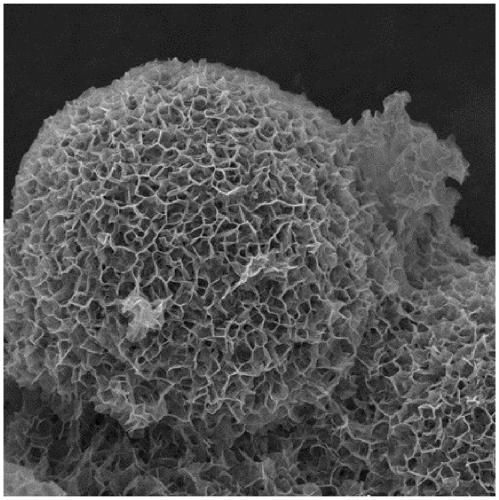

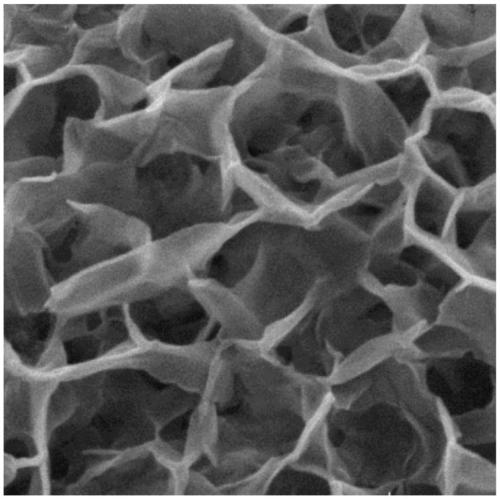

[0051] (2) will Co 3 o 4 and 8.640 g of Na 2 S was added to 180mL aqueous solution, sonicated for 0.5h-1h to form a uniform dispersion solution, hydrothermally reacted at 120°C for 24h, and then annealed at 500°C for 2h to obtain three-dimensional cobalt sulfide;

[0052] (3) Transfer 100 mg of ...

Embodiment 2

[0057] The embodiment of the present invention provides the second composite wave-absorbing material, the preparation method of which is as follows:

[0058] (1) Weigh the chemicals used, cobalt dichloride hexahydrate, urea, and ammonium fluoride, with a mass of 3.842g, 3.964g, and 0.977g, respectively, and add them to 330mL of distilled water, and ultrasonically stir for 0.5h-1h to form a uniform dispersion solution. Transferred to a hydrothermal reactor, 120 ° C hydrothermal reaction for 5 h, naturally cooled to room temperature, the obtained product was kept at 350 ° C in an argon atmosphere for 2 h, and then naturally cooled to room temperature to obtain 1.446 g of Co 3 o 4 ;

[0059] (2) will Co 3 o 4 and 8.640 g of Na 2 S was added to 180mL aqueous solution, sonicated for 0.5h-1h to form a uniform dispersion solution, hydrothermally reacted at 150°C for 24h, and then annealed at 500°C for 2h to obtain three-dimensional cobalt sulfide;

[0060] (3) Transfer 100 mg of...

Embodiment 3

[0064] The embodiment of the present invention provides a third composite wave-absorbing material, the preparation method of which is as follows:

[0065] (1) Weigh the chemicals used, cobalt dichloride hexahydrate, urea, and ammonium fluoride, with a mass of 3.842g, 3.964g, and 0.977g, respectively, and add them to 330mL of distilled water, and ultrasonically stir for 0.5h-1h to form a uniform dispersion solution. Transferred to a hydrothermal reactor, 120 ° C hydrothermal reaction for 5 h, naturally cooled to room temperature, the obtained product was kept at 350 ° C in an argon atmosphere for 2 h, and then naturally cooled to room temperature to obtain 1.446 g of Co 3 o 4 ;

[0066] (2) will Co 3 o 4 and 8.640 g of Na 2 S was added to 180mL aqueous solution, sonicated for 0.5h-1h to form a uniform dispersion solution, hydrothermally reacted at 180°C for 24h, and then annealed at 500°C for 2h to obtain three-dimensional cobalt sulfide;

[0067] (3) Transfer 100 mg of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com