Integral explosion-proof film for black screen and preparation method thereof

A technology of black screen and explosion-proof film, which is applied in the field of explosion-proof film for integrated black screen and its preparation, can solve the problems of decreased light transmittance of glass, low glass yield, etc. produced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

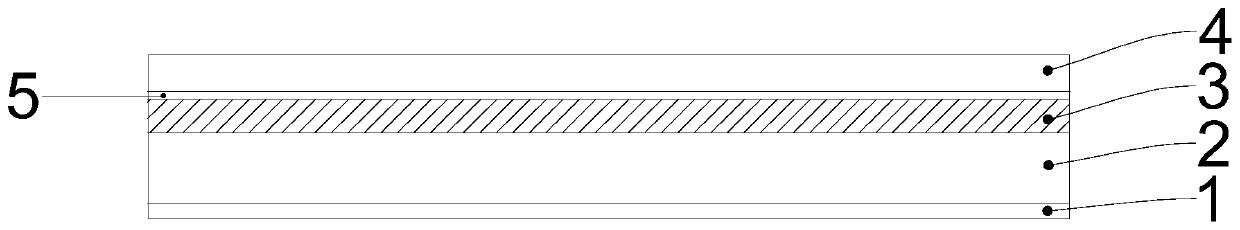

Image

Examples

preparation example Construction

[0035] The preparation method of explosion-proof film for integrated black screen is as follows:

[0036] Step 1. Weigh the resin, solvent, black color paste, and dispersant in sequence and add them to the liquid mixing tank, stir and disperse for 10-30 minutes, and let stand for defoaming to obtain a coating liquid with a solid content of 20-60%;

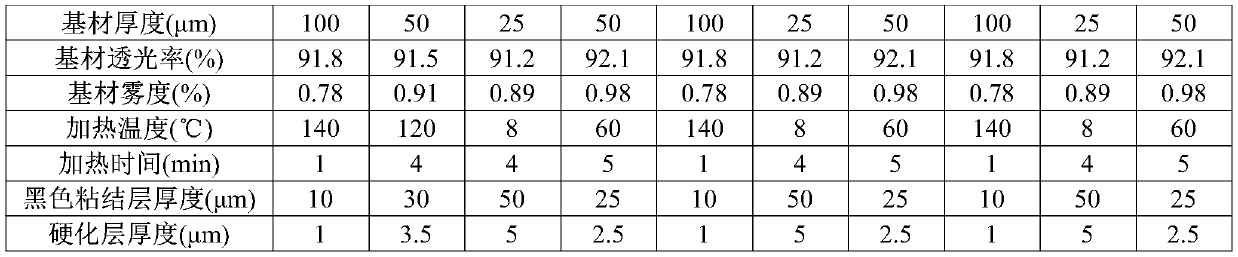

[0037] Step 2: Apply the prepared coating solution evenly on one side of the substrate layer 2, heat at 60-140°C for 1-5 minutes, and then fully cure by ultraviolet light or heating to obtain a black adhesive layer 3;

[0038] Step 3: Attach the release film layer 4 to the surface of the black adhesive layer 3 to ensure no air bubbles;

[0039] Step 4: Coating functional coating 1 on the other side of the substrate, and curing by ultraviolet light to obtain an explosion-proof film for an integrated black screen;

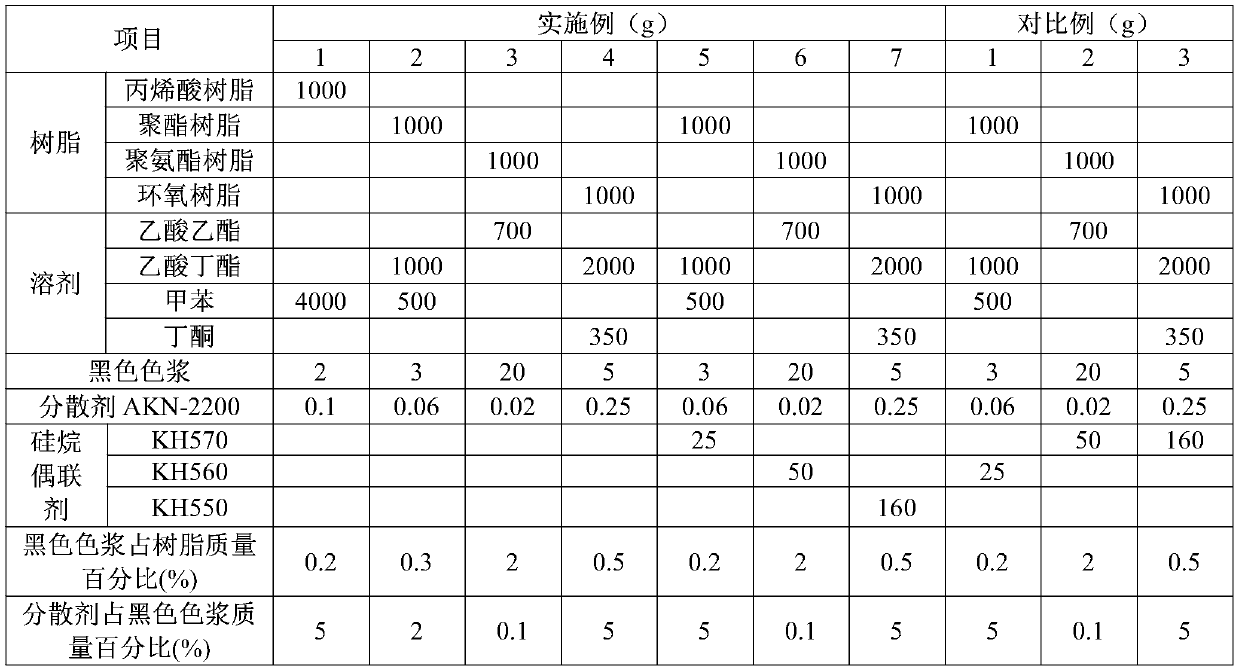

[0040] Wherein, the resin is one of acrylic resin, polyester resin, polyurethane resin and epoxy resin; the solvent is...

Embodiment 5

[0045] In Example 5, after step 2, the prepared coating solution was uniformly coated on one side of the substrate layer, and then left to stand for 5 minutes before heating and subsequent treatment. The treatment method of Comparative Example 1 was consistent with that of Example 5.

Embodiment 6

[0046] In Example 6, after step 2, the prepared coating liquid was uniformly coated on one side of the substrate layer, and then left to stand for 10 minutes before heating and subsequent treatment. The treatment method of Comparative Example 2 was consistent with that of Example 6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com