Fireproof and flame-retardant type sand surface waterborne polyurethane finishing coat and a preparation method thereof

A water-based polyurethane, fire-resistant and flame-retardant technology, applied in polyurea/polyurethane coatings, fire-resistant coatings, coatings, etc., can solve the problems of operator injury, increased risk of fire and explosion, pollution of the environment, etc., and achieve enhanced weather resistance , High fullness of the coating, the effect of increasing the hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0076] A kind of preparation method of above-mentioned fire retardant type sand surface waterborne polyurethane finish paint, comprises the following steps:

[0077] S1, preparation of component A

[0078] S1.1. Add water, water-based acrylic dispersion hydroxyl resin, halogen-free flame-retardant water-based polyurethane resin, defoamer, dispersant and wetting agent in the dispersion tank according to mass percentage, and carry out medium-speed dispersion, medium-speed dispersion The speed is 600~800r / min;

[0079] S1.2. Slowly add nano-titanium dioxide, nano-zinc borate, magnesium hydroxide, aluminum hydroxide, calcined kaolin, sand flour and water-based wax powder, add water to rinse the cylinder wall, and disperse at high speed for 20-50 minutes until the fineness is ≤40 microns. Add leveling agent, thickener, preservative and antifungal agent at medium and low dispersing speed. The speed is 1000-1500r / min, and the fineness and viscosity of the finished product are teste...

Embodiment 1

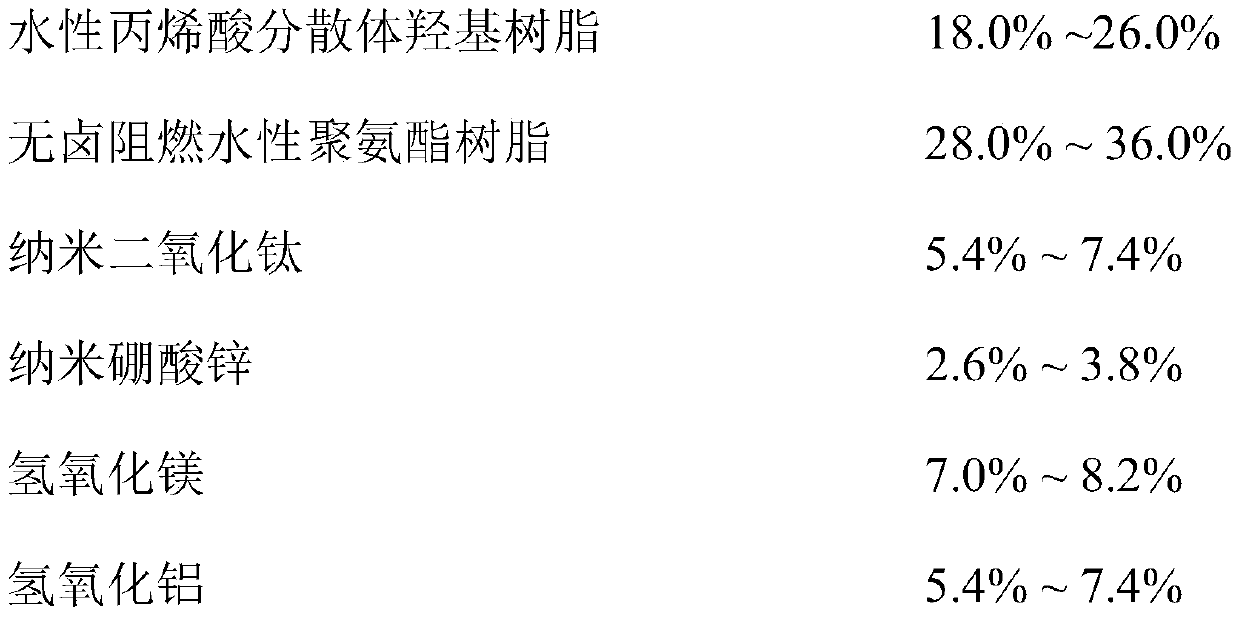

[0086] A kind of fire-proof and flame-retardant sand surface water-based polyurethane topcoat comprises the following components by mass percentage:

[0087] A component (main paint)

[0088]

[0089] B component (curing agent)

[0090] Hydrophilic aliphatic polyisocyanate 40.0%

[0091] Lipophilic aliphatic polyisocyanate 36.0%

[0092] Propylene Glycol Diacetate 24.0%

[0093] Component A (main paint) and component B (curing agent) are mixed according to the NCO / OH equivalent ratio of n(-NCO):n(-OH)=1.2~1.3, that is, the -NCO functional group in component A and The equivalent molar ratio of -OH functional groups in component B is 1.2-1.3.

[0094] A kind of preparation method of above-mentioned fire retardant type sand surface waterborne polyurethane finish paint, comprises the following steps:

[0095] S1, preparation of component A

[0096] S1.1. Add water, water-based acrylic dispersion hydroxyl resin, halogen-free flame-retardant water-based polyurethane resin, ...

Embodiment 2

[0105] A kind of fire-proof and flame-retardant sand surface water-based polyurethane topcoat comprises the following components by mass percentage:

[0106] A component (main paint)

[0107]

[0108] B component (curing agent)

[0109] Hydrophilic aliphatic polyisocyanate 42.0%

[0110] Lipophilic aliphatic polyisocyanate 35.0%

[0111] Propylene Glycol Diacetate 23.0%

[0112] Component A (main paint) and component B (curing agent) are mixed according to the NCO / OH equivalent ratio of n(-NCO):n(-OH)=1.2~1.3, that is, the -NCO functional group in component A and The equivalent molar ratio of -OH functional groups in component B is 1.2-1.3.

[0113] A kind of preparation method of above-mentioned fire retardant type sand surface waterborne polyurethane finish paint, comprises the following steps:

[0114] S1, preparation of component A

[0115] S1.1. Add water, water-based acrylic dispersion hydroxyl resin, halogen-free flame-retardant water-based polyurethane resin, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact resistance | aaaaa | aaaaa |

| Impact resistance | aaaaa | aaaaa |

| Impact resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com